Blow fill foundation treating method and gas injection draining method therefor

A treatment method, gas injection and drainage technology, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as shortening the growth time of foundation strength, accelerating foundation drainage consolidation, and difficulty in drainage of dredged fill soil, etc., to achieve beneficial Long-term strength and effective maintenance, enhanced hydraulic infiltration slope, and improved internal soil permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

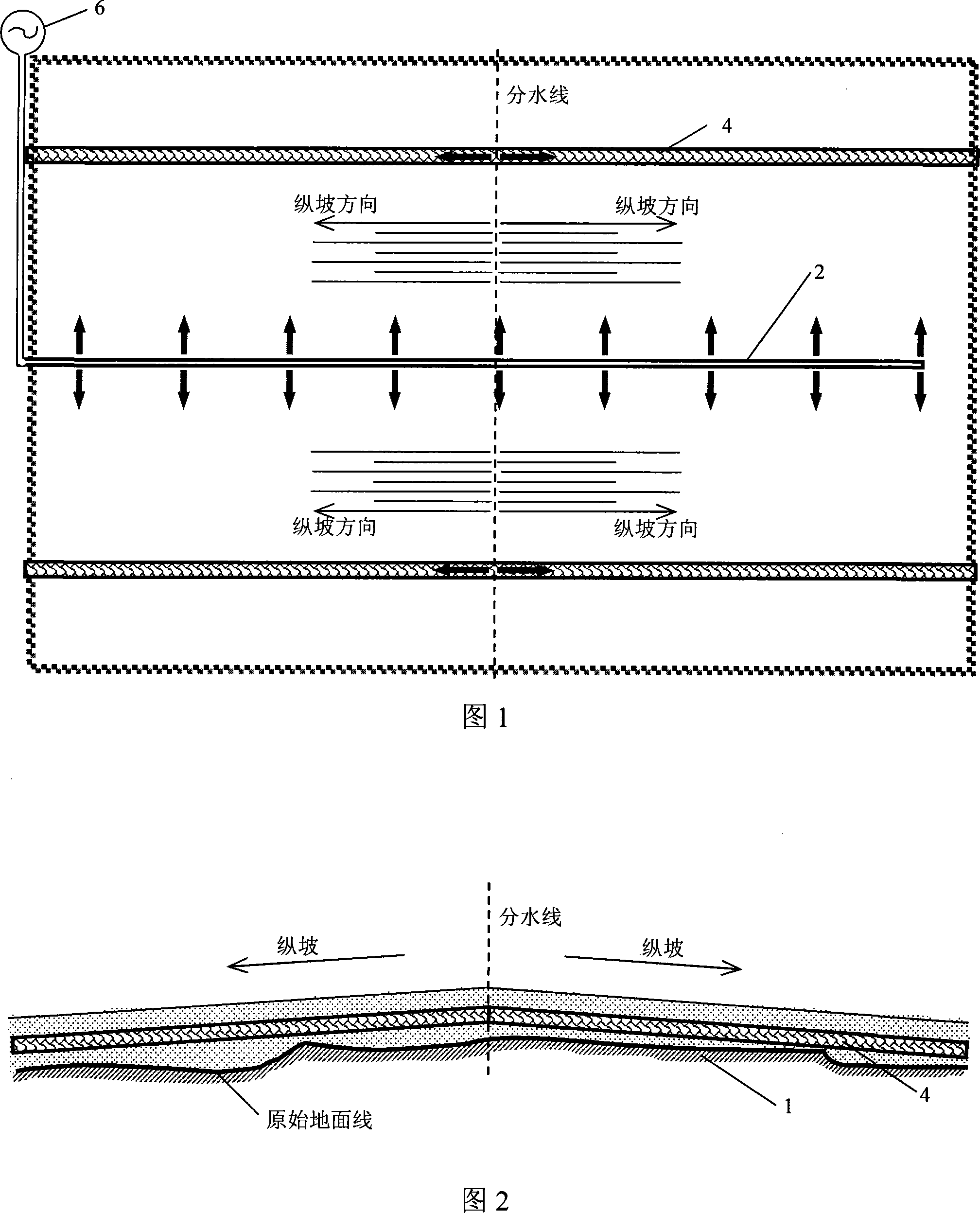

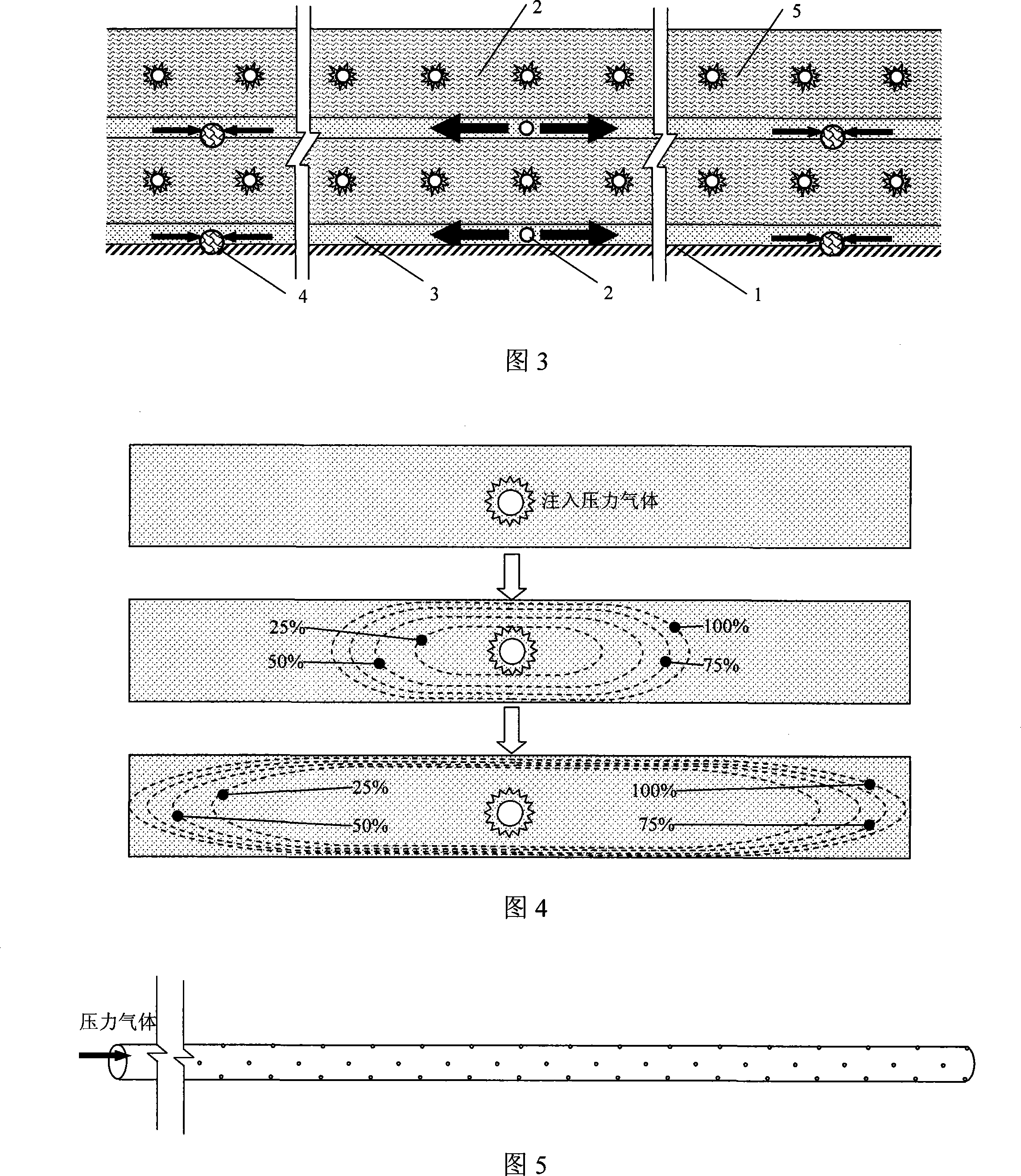

[0037] The invention is based on the conventional layered soil filling method for reducing the length of the consolidation seepage path of the soil layer, combined with an air injection drainage device to form a new type of filling soil foundation treatment method. This treatment method is not carried out after the foundation of the dredger fill is formed, but preparations are made before the fill, and the foundation treatment is carried out while the fill is carried out, which can significantly improve the treatment efficiency of the fill foundation and shorten the construction period. As shown in Figures 1 to 5, there are: 1. Dredging filling site; 2. Air injection pipe; 3. Water delivery sand cushion; 4. Drainage blind ditch; 5. Dredging fill; 6. Air supply device.

[0038] The foundation treatment system in the present invention is mainly composed of three parts: a gas injection device, a drainage system and a dredging and filling soil layer (5). The thickness of a single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com