Compressed air engine

A compressed air and engine technology, which is applied to engine components, machines/engines, non-variable engines, etc., can solve the problems of energy waste, high energy consumption of compressed air engines, etc., and achieve low production costs and high energy utilization , the effect of small energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

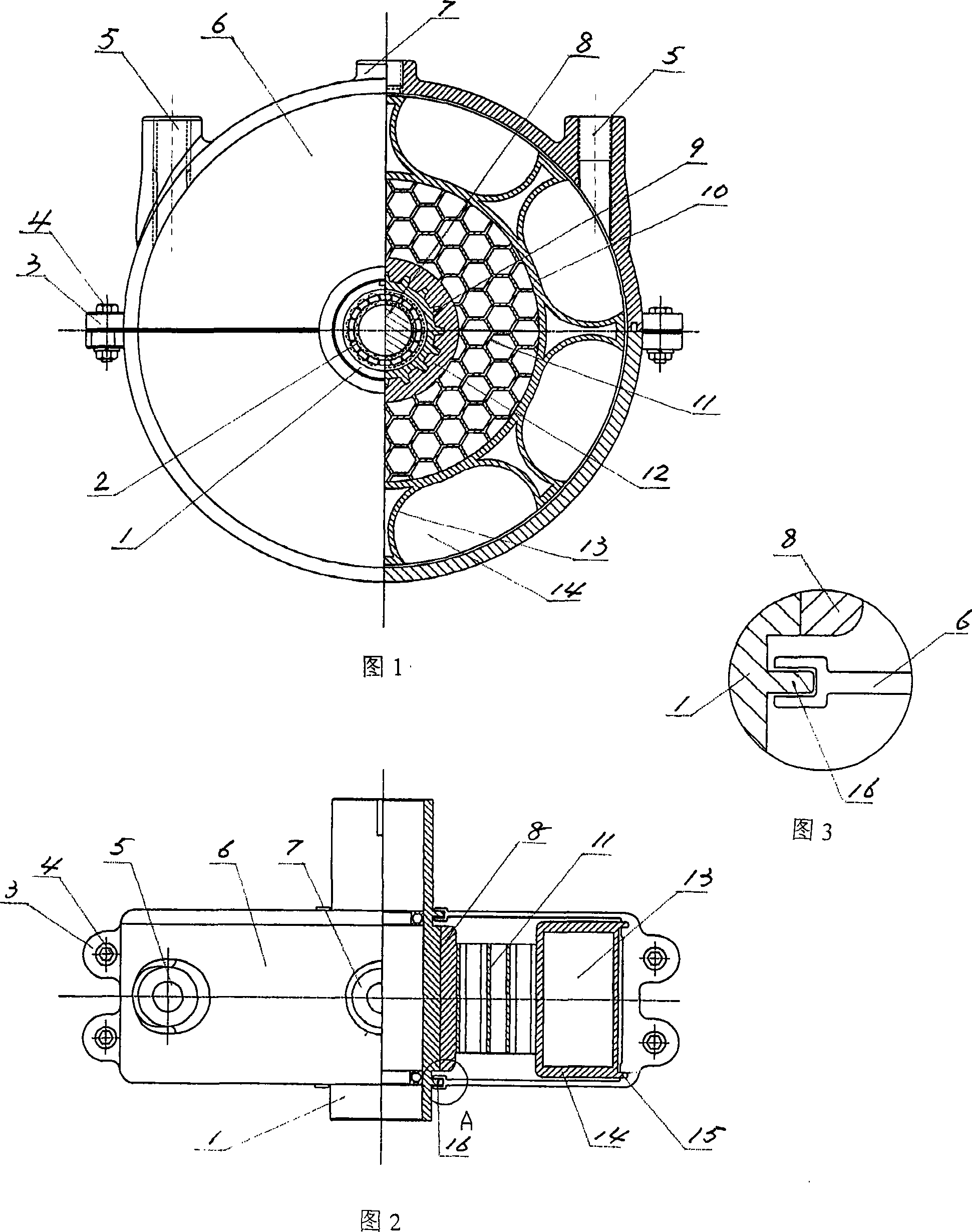

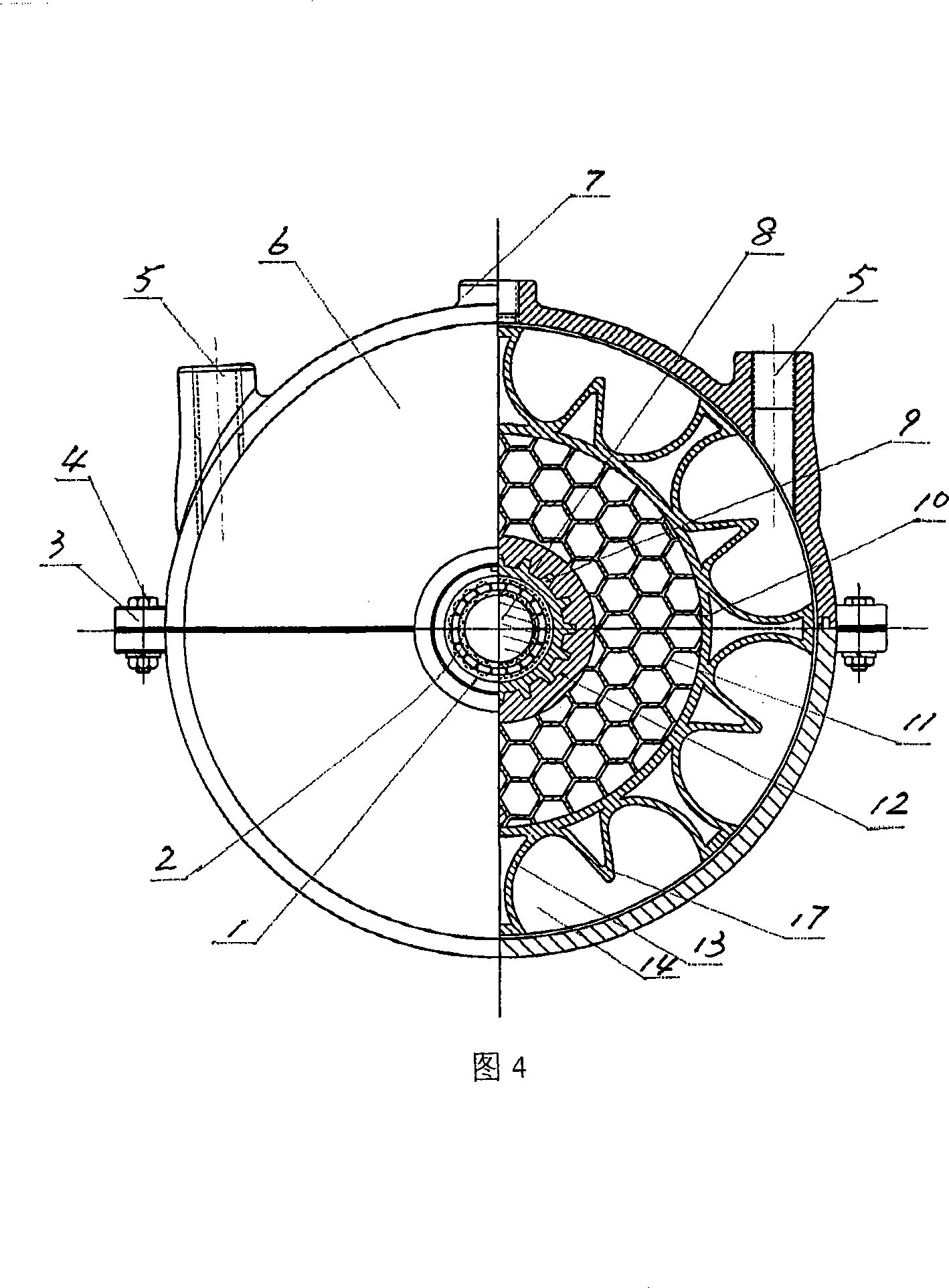

[0013] As shown in FIGS. 1 and 2 , the compressed air motor of the present invention comprises a casing 6 . The shell is cylindrical, and an air inlet 5 and an air outlet 7 are processed on the shell walls around it. The air inlet 5 wherein includes a forward air inlet and a reverse air inlet, the longitudinal centerlines of the two air inlets are parallel, and they are all on the same semicircular shell wall of the shell 6 . And the air outlet 7 is between the two air inlets 5 . Both ends of the shell 6 are provided with a center hole, and a shaft sleeve 1 is installed in the center hole. As shown in Fig. 3, a circumferential groove is processed on the inner circle of the center hole on both ends of the shell 6, and a circumferential boss 16 is processed on the outer circle of the shaft sleeve 1 corresponding to the circumferential groove. The circumferential boss 16 is sealed and movable into the circumferential groove on the inner circle of the center hole of the two end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com