Floating rubber damping vibration attenuation device

A vibration reduction device and damping technology, which is applied in non-rotational vibration suppression, solid separation, chemical instruments and methods, etc., can solve the problems of non-adjustable displacement of rubber pads, limited load weight, low efficiency, etc., and achieve vibration reduction in a wide frequency range Adaptability, simple structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

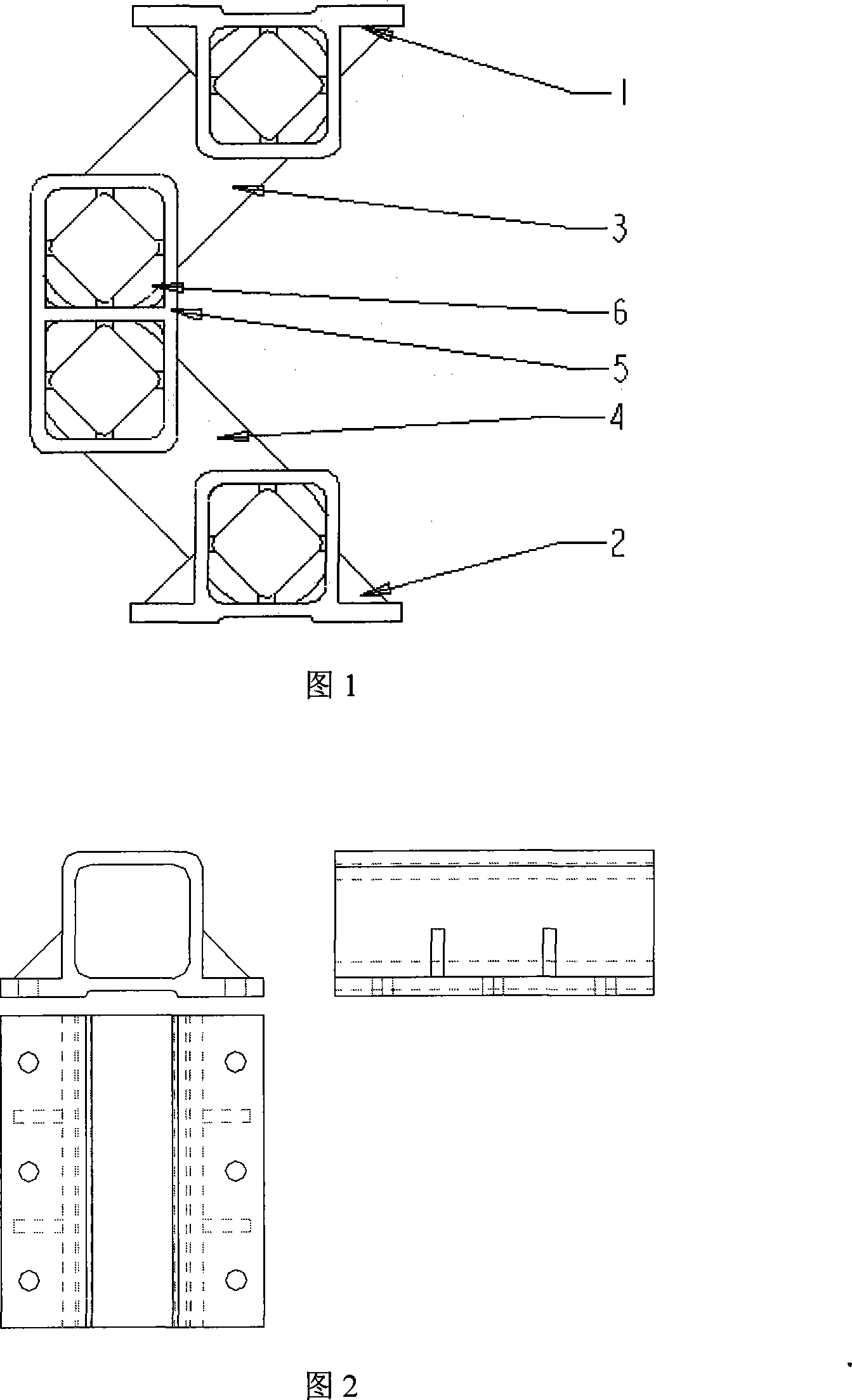

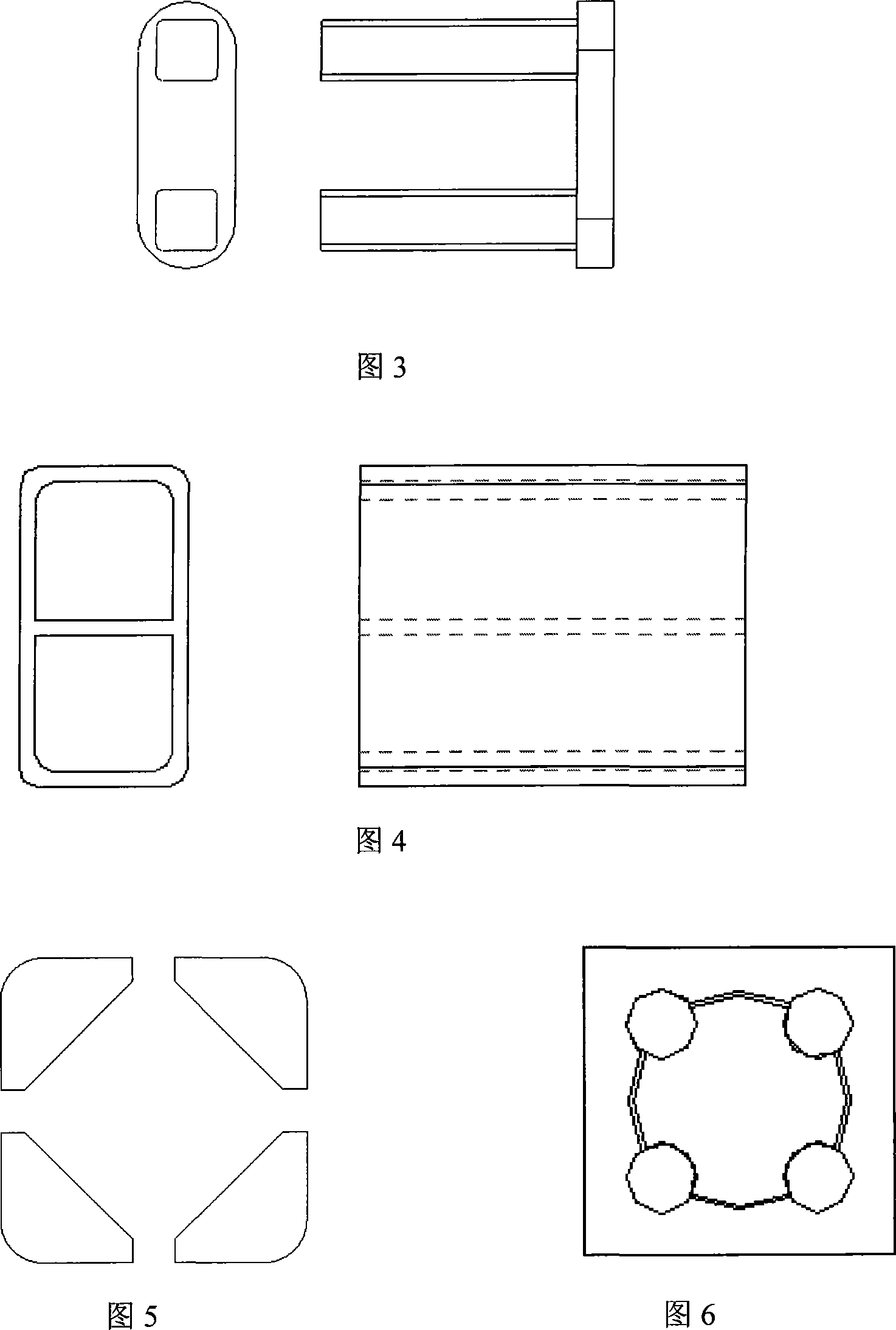

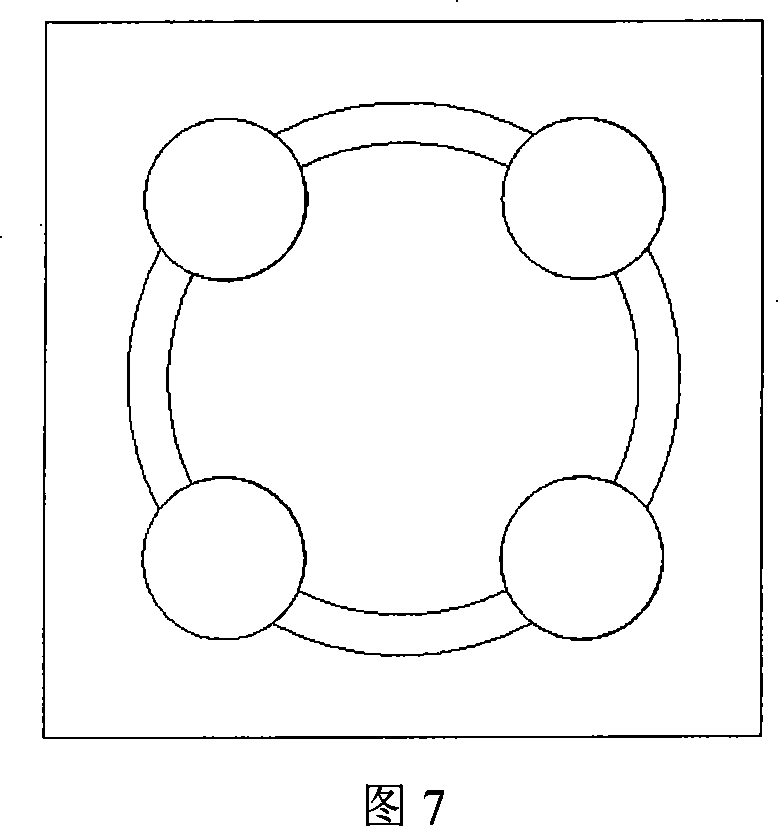

[0014] In conjunction with Fig. 1, the floating rubber damping and vibration reduction device of the present invention, four sets of damping rubber shock absorbing block units 6 are respectively installed in the upper movable support 1, the lower fixed support 2 and the floating box 5, wherein two groups are respectively installed in the floating box 5 in the two holes. The upper swing power arm 3 is hinged with the upper movable support 1 and the floating box 5 respectively, and the lower swing power arm 4 is hinged with the lower fixed support 2 and the floating box 5 respectively.

[0015] Among them, the buffer of the vibration damping device unit 6 adopts the composite vibration damping structure of the upper and lower swing arms 3, 4 and damping rubber, so that the vibration damping device can not only achieve high energy consumption, but also meet the large displacement vibration excited by the main vibration. . The upper and lower swing arms 3, 4 are used to rotate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com