System and method for testing dynamic friction parameter

A parametric testing and dynamic friction technology, applied in the testing field, can solve the problems of no LuGre friction parameters, no equipment, no theoretical basis for system decoupling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

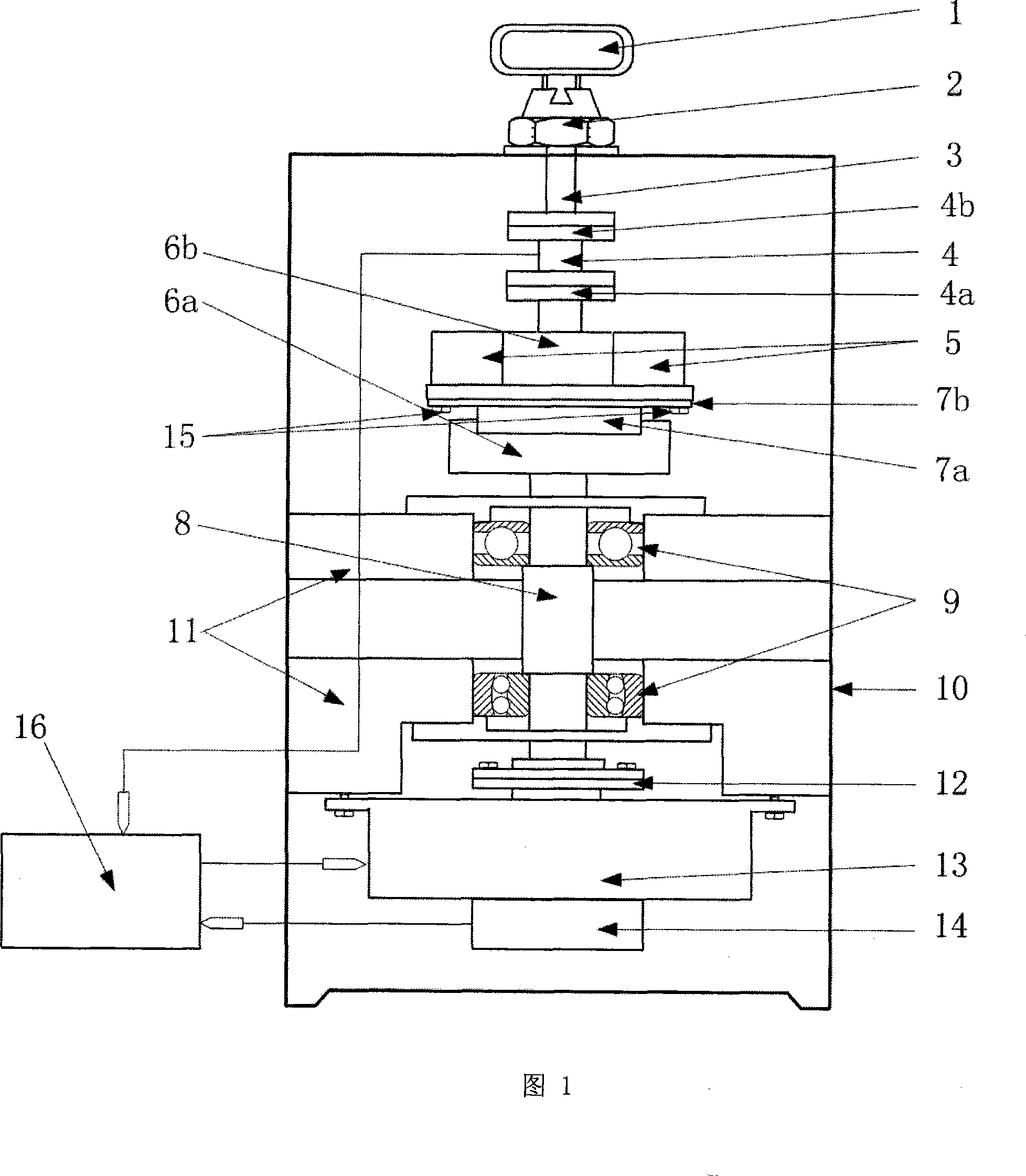

[0060] 1, the test system of the present invention includes: the mechanical structure consists of a handle 1, a locking mechanism 2, a torque sensor 4, a test piece and a weight fixing device 6, a test piece 7, a drive shaft 8, a frame 10, a horizontal The bracket 11, the torque motor 13, the absolute encoder 14 and the controller 16. The test piece and weight fixing device 6 are divided into upper and lower layers, the surface of the lower layer 6a is provided with a square groove, the upper layer 6b is a stepped shaft, the upper and lower flanges 4a and 4b are fixedly connected to the torque sensor, and the frame 10 is a whole The cast rectangular parallelepiped frame structure is easy to operate. There is a two-layer horizontal bracket 11 in the middle to increase rigidity. The drive shaft 8 is mounted on the horizontal bracket 11 through a bearing 9 and can rotate around its axis. The absolute encoder 14 is fixed to the torque motor 13, and is coaxially installed on the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com