Aluminum coil connecting method of domestic electric machine

A household motor and connection method technology, which is applied in the direction of connecting contact materials, manufacturing motor generators, electrical components, etc., can solve problems such as damage, falling off of contact parts, and inability to produce aluminum coils, so as to improve durability and prevent falling off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

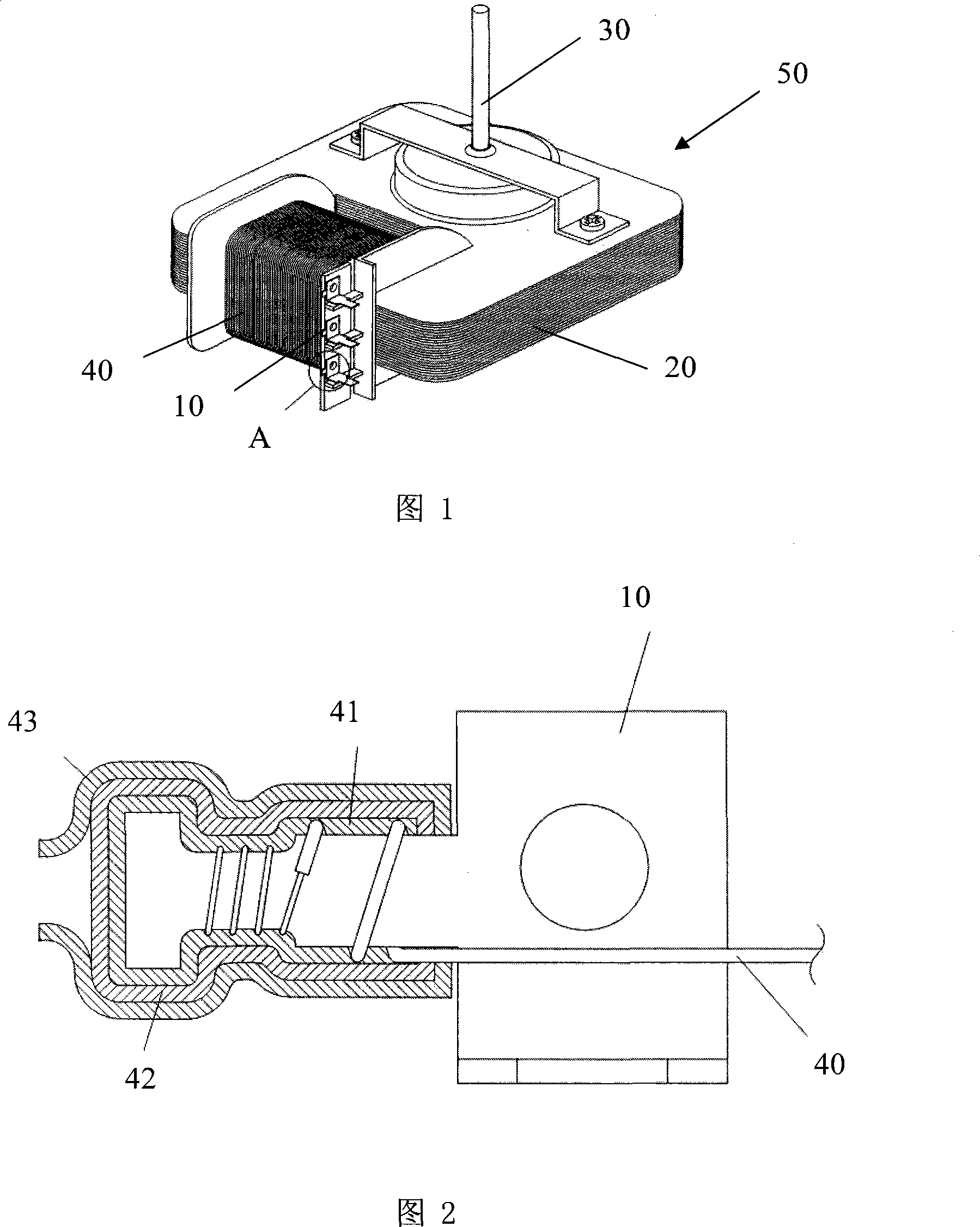

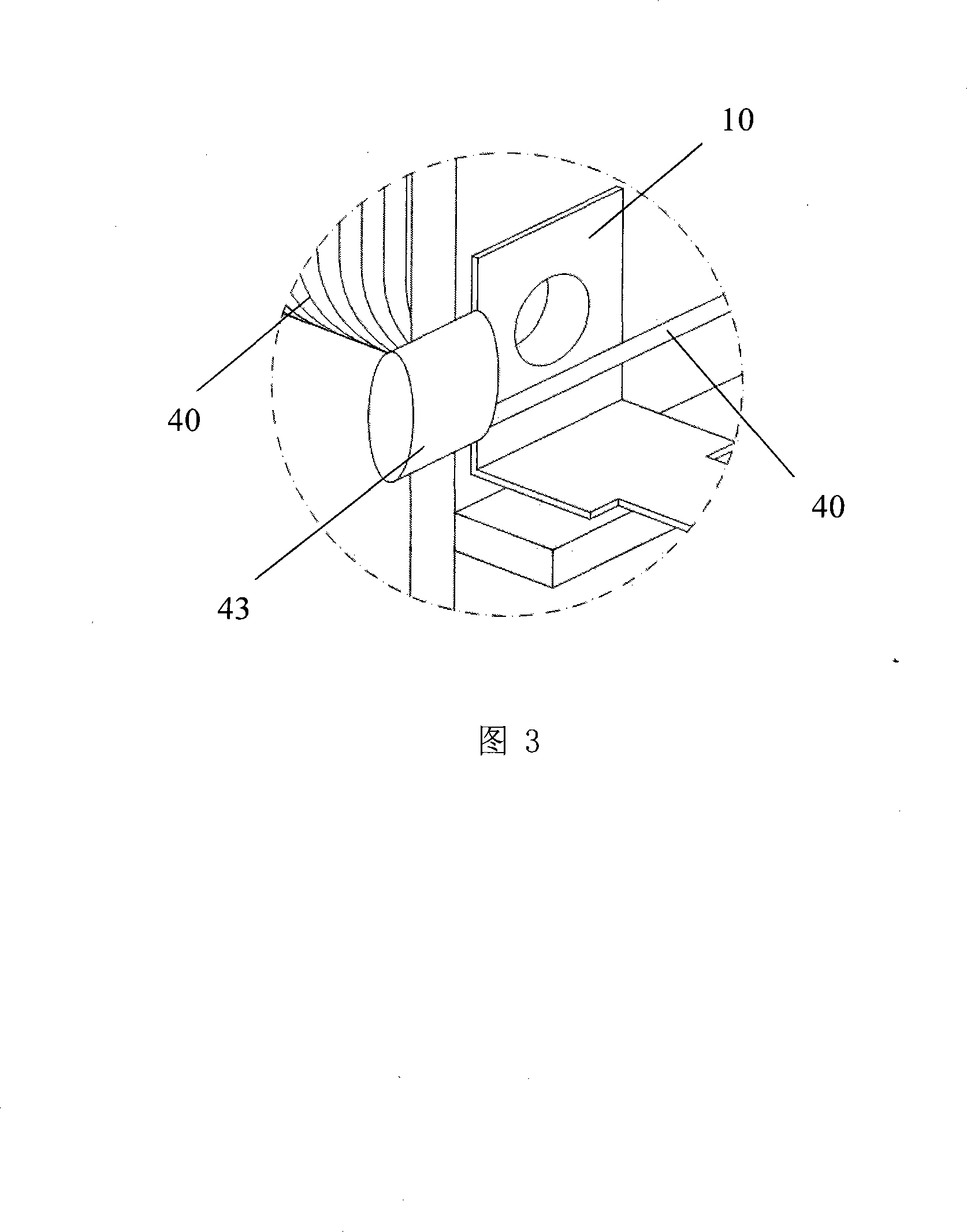

[0015] As shown in FIGS. 1 to 3 , the household motor 50 provided by the present invention is provided with a terminal 10 , and the terminal 10 can power on the drive shaft 30 disposed on the magnetic core 20 to make the drive shaft 30 rotate.

[0016] The coil used for the above-mentioned household motor 50 is an aluminum coil 40. The connection method between the aluminum coil 40 and the terminal 10 is to first weld the aluminum coil 40 on the terminal 10 to form a welding part 41, and then coat the welding part 41 with One layer of epoxy resin layer 42 has anti-corrosion effect, and finally, the outer cover of epoxy resin layer 42 is covered with a cover 43 capable of buffering the impact force suffered by epoxy resin layer 42 and sealing it.

[0017] The household motor 50 provided by the present invention will be described in detail below.

[0018] In the present invention, the aluminum coil 40 is connected to the terminal 10 of the household motor 50 by welding to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com