Aqueous promoter for single-component dissolvent type silver powder paint

A water-based additive and solvent-based technology, applied in the field of paint additives, can solve the problems of high price and affecting the storage stability of paint, and achieve the effect of cheap price, improved anti-corrosion and decorative nature, and simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

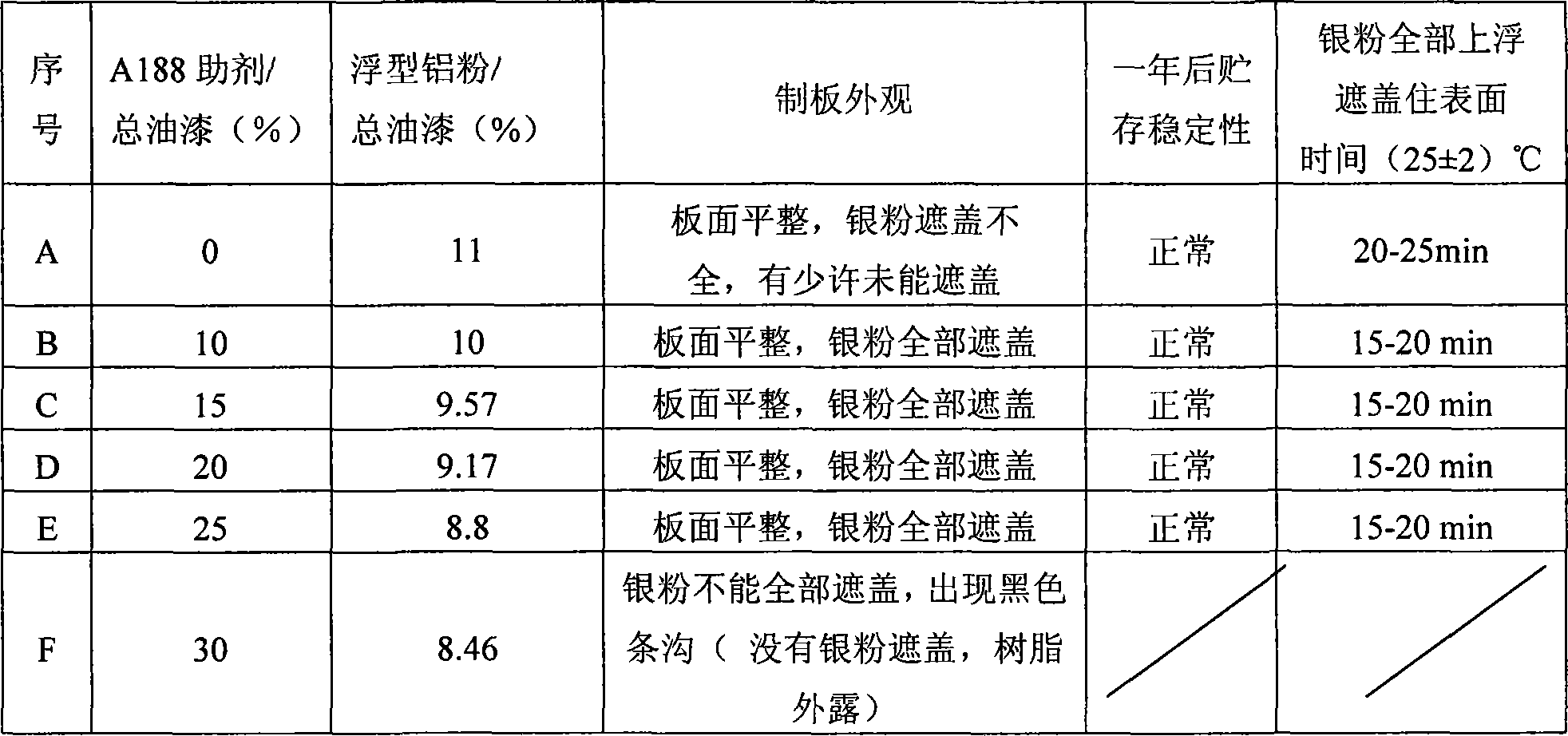

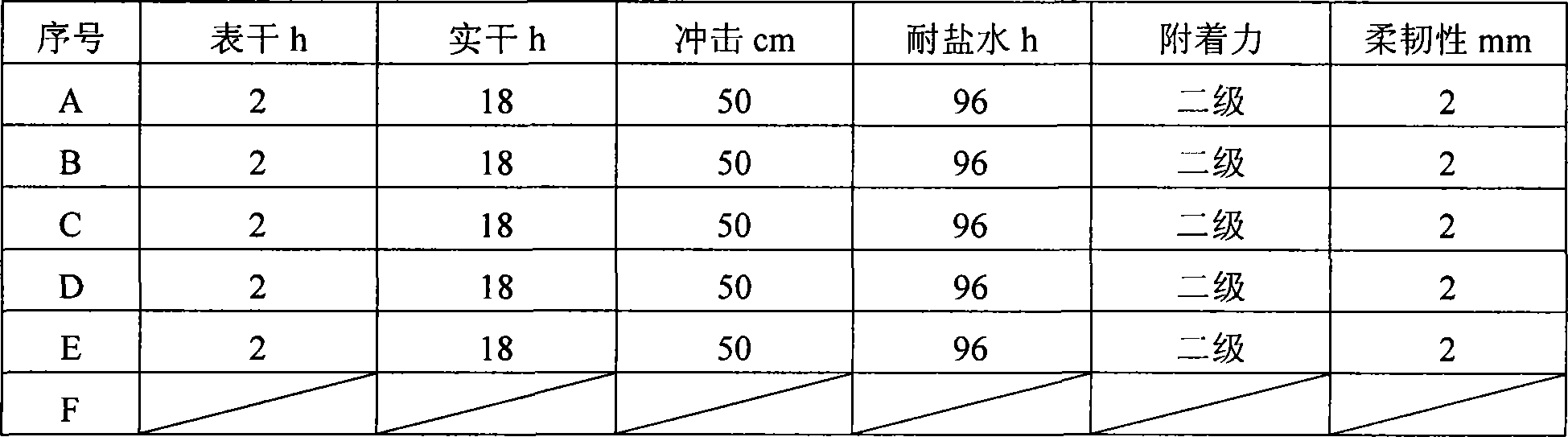

Method used

Image

Examples

Embodiment 1

[0026] Weigh 1000 kg of tap water into a stainless steel tank, start stirring (800-1000 rpm), slowly add 1.94 kg of TFC-1 water-based dispersant, 7.76 kg of KF-01 water-based preservative, stir for 5 minutes and then slowly Add 19.4 kg of sodium alkylsulfonate anionic surfactant, stir for 20-30 minutes, and fill it in a plastic barrel (or non-iron barrel) for use. When adding to paint, add with stirring at 600-1000 rpm.

Embodiment 2

[0028] Weigh 800 kg of tap water into a stainless steel tank, start stirring (800-1000 rpm), slowly add 0.78 kg of 5041 water-based dispersant, 7.06 kg of AlexF-250 water-based preservative, and slowly add alkane after stirring for 5 minutes. 7.84 kg of sodium sulfonate anionic surfactant, stirred for 20-30min, filled with plastic barrels (or non-iron barrels) for use. When adding to paint, add with stirring at 600-1000 rpm.

Embodiment 3

[0030] Weigh 800 kg of tap water into a stainless steel tank, start stirring (800-1000 rpm), slowly add 0.78 kg of 5040 water-based dispersant, 7.06 kg of AlexF-251 water-based preservative, and slowly add alkane after stirring for 5 minutes. 7.84 kg of sodium sulfonate anionic surfactant, stirred for 20-30min, filled with plastic barrels (or non-iron barrels) for use. When adding to paint, add with stirring at 600-1000 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com