Cooler for heater-containing box

A technology of cooling device and storage box, which is applied in the box field of the machine, and can solve problems such as poor welding, time-consuming work, reduction of opening height and air path height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

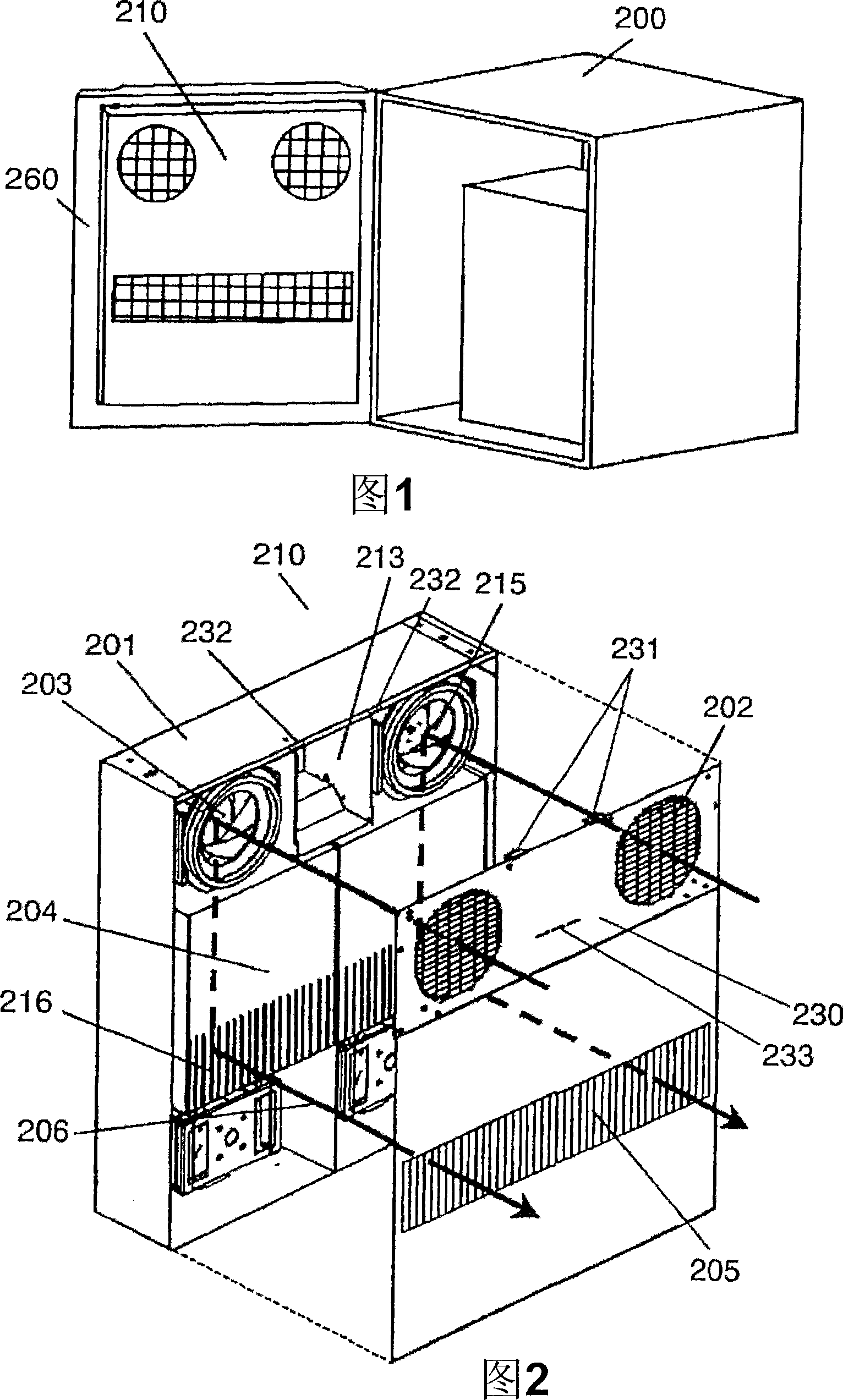

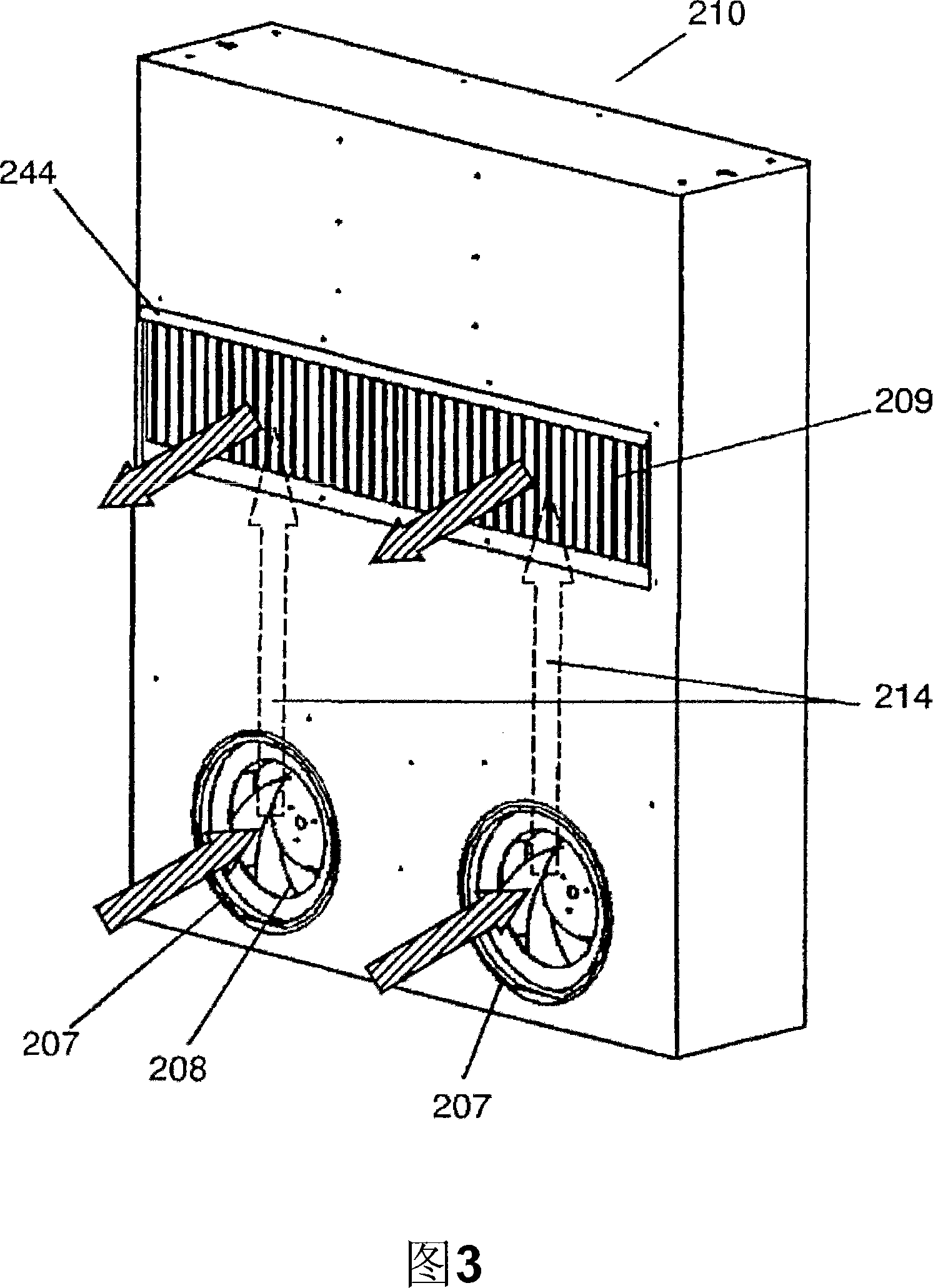

[0169] Hereinafter, Embodiment 1 of the present invention will be described with reference to FIGS. 1 to 3 .

[0170] Fig. 1 is an installation diagram of a heating element storage box cooling device in Embodiment 1 of the present invention, Fig. 2 is an indoor appearance view and a structural diagram of a heating element storage box cooling device in Embodiment 1 of the present invention, and Fig. 3 is The exterior view of the outdoor side of the heating element storage box cooling device in Embodiment 1 of the present invention shows a state in which a plurality of heating element storage box cooling devices 100 are installed in the horizontal direction (each figure shows a case where two are installed).

[0171] The heating element storage box cooling device 210 is installed on the door 260 of the heating element storage box 200, forming a "door-integrated" installation structure.

[0172] In addition, although the heating element storage box cooling device 210 is installed...

Embodiment approach 2

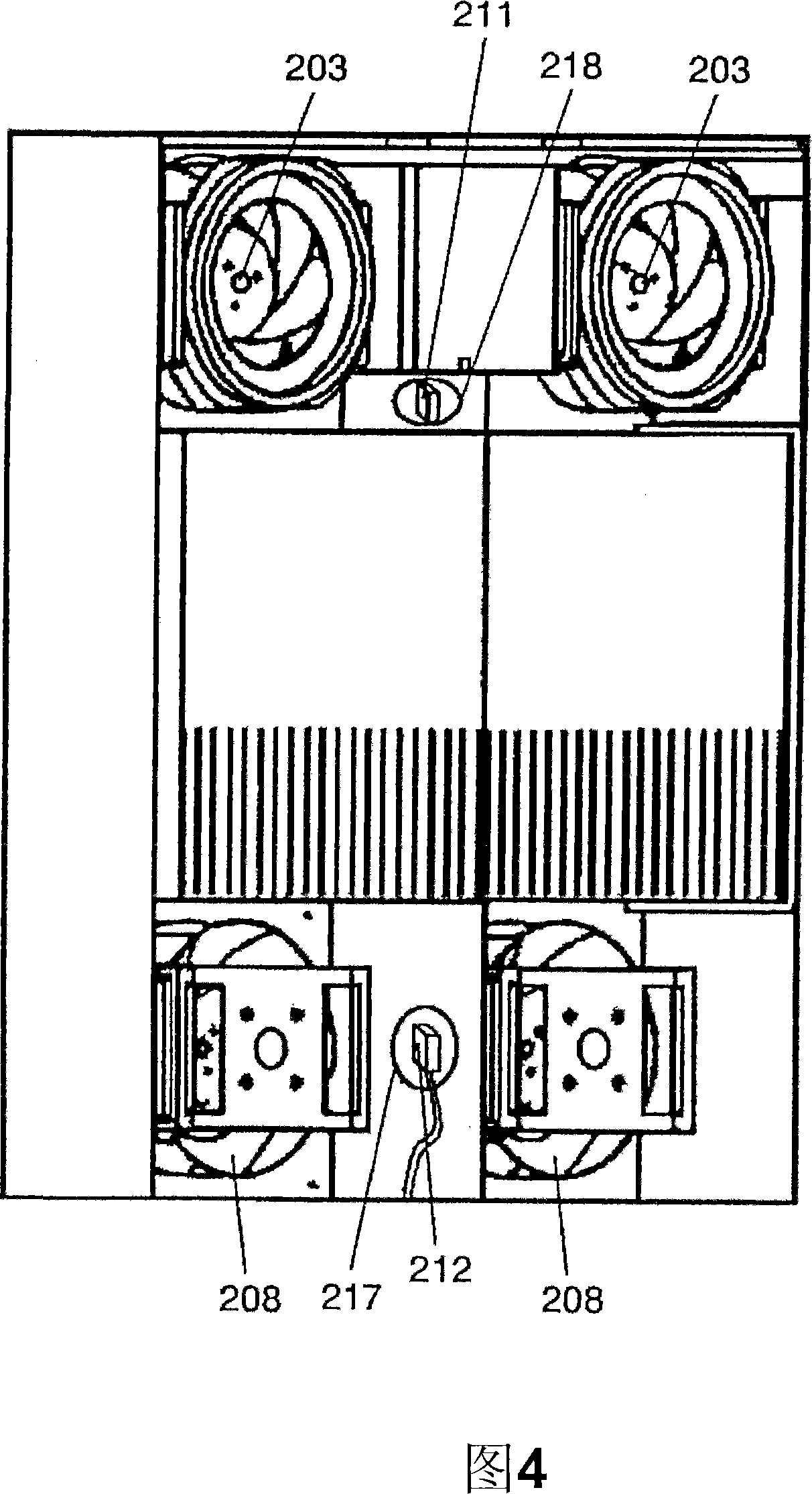

[0187] Next, Embodiment 2 of the present invention will be described with reference to FIG. 4 .

[0188] Fig. 4 is a block diagram showing a temperature detector-related structure of the heating element storage box cooling device according to Embodiment 2 of the present invention, showing a state in which a plurality of heating element storage box cooling devices are installed. In FIG. 4 , the same reference numerals are used for the same constituent elements as those in FIGS. 2 and 3 , and description thereof will be omitted.

[0189] The internal air temperature detector 211 that detects the temperature of the internal air is arranged on the internal air through hole 218 provided between the internal air blowers 203 of the heating element storage box cooling devices A, and the external air temperature of the external air temperature is detected. The detector 212 is disposed on the outside air through-hole 217 provided between the outside air blowers 208 of the heating elemen...

Embodiment approach 3

[0192] Next, Embodiment 3 of the present invention will be described with reference to FIG. 5 .

[0193] Fig. 5 is a structural diagram related to a heat insulator of the heating element storage box cooling device according to Embodiment 3 of the present invention. In FIG. 5 , the same reference numerals are used for the same constituent elements as those in FIG. 2 , and description thereof will be omitted.

[0194] On the heating element storage box cooling device 210, for positioning the heat exchanger 204, for example, a heat insulator 219 made of foamed styrene is provided with a guide rail 220 formed at the edge to be connected to the heat exchanger 204. The lower end abuts against the convex wall.

[0195] According to the above structure, the heat exchanger 204 can be installed and positioned so that the lower end of the heat exchanger 204 abuts on the guide rail 220, so the installation is easy, the arrangement structure is simple, and the production and maintenance a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com