Blast-furnace furnace-arch maintenance robot movement mechanism

A motion mechanism and robot technology, applied in the direction of manipulators, auxiliary devices, claw arms, etc., can solve the problems of workers falling down, life-threatening, low efficiency, etc., to reduce friction and wear, facilitate control, and meet engineering precision requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

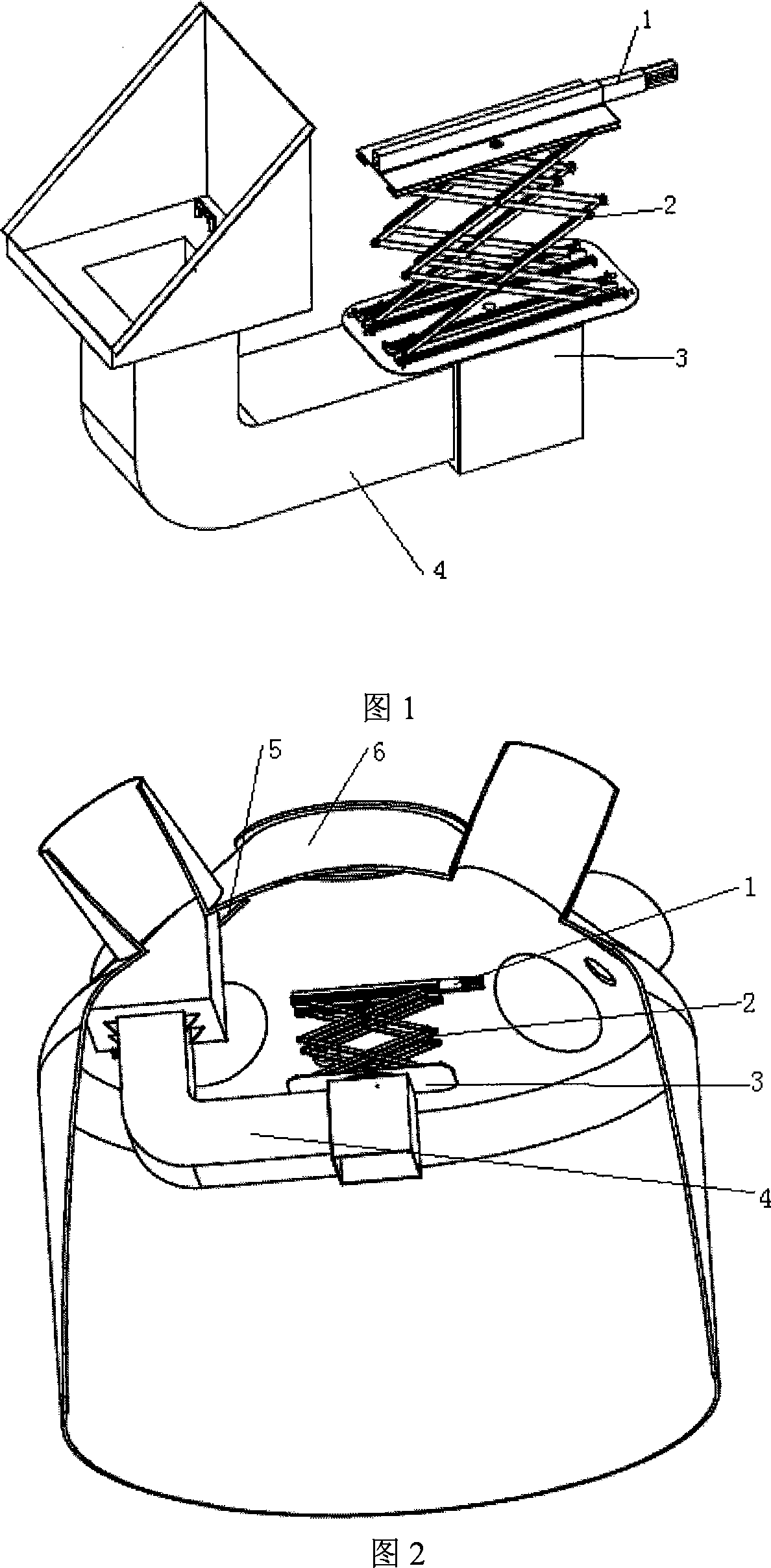

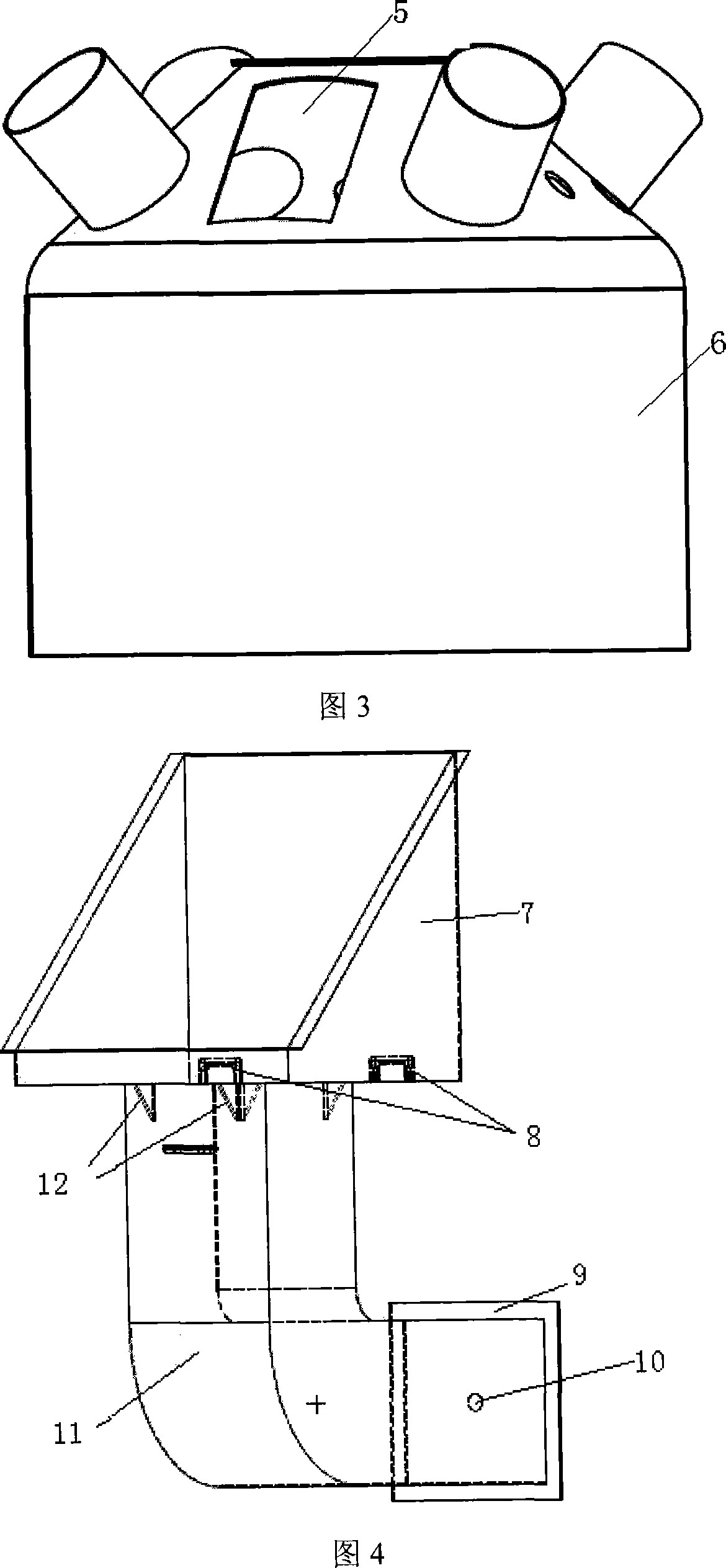

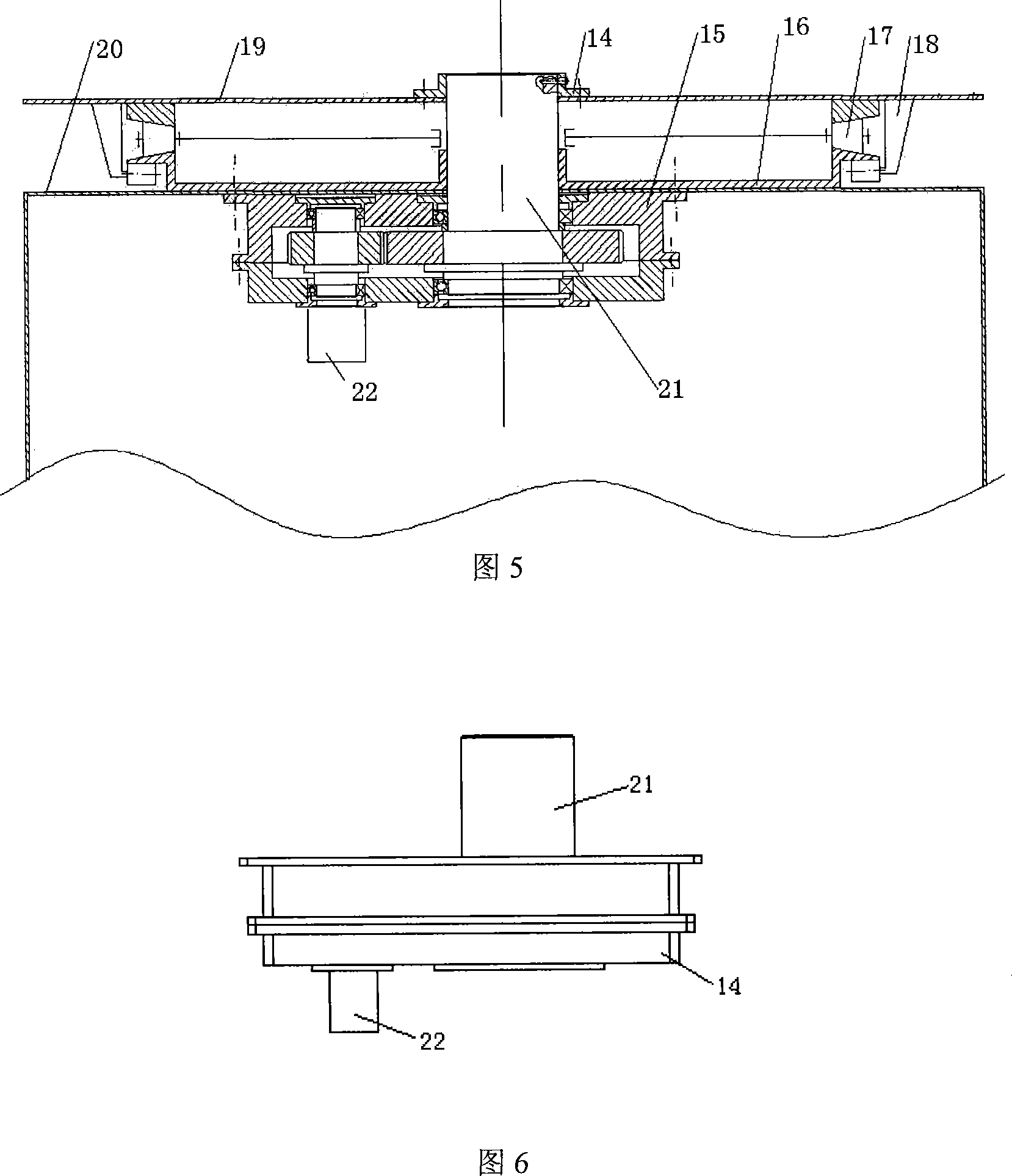

[0026] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing: Referring to Fig. 1, Fig. 2, Fig. 3 and Fig. 4, this blast furnace top maintenance robot kinematic mechanism adopts the mechanical kinematic mechanism of cylindrical coordinate type, and it contains three degrees of freedom, In this structure, three sub-mechanisms each realizing one degree of freedom movement are assembled together and fixed on the support frame 4 to form an overall structure. Its specific implementation is completed through the coordinated operation of three sub-organizations, which rotate or move in the cylindrical coordinate space, and finally make the working tool at the end reach the expected surface of the inner wall of the blast furnace roof.

[0027] Referring to Fig. 4 and Fig. 5, the support frame 4 is a large "L"-shaped integral shell 11, the thick end part 9 of the head 7 is thin, and the head 7 is in contact with the manhole 5 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com