Drive mechanism for fused mass milling degree regulating device of milling extrusion pressing granulation machine group

A technology of adjusting device and driving mechanism, which is applied in the field of extrusion granulation unit, can solve the problems of inconvenient operation and large rotating torque of the valve plate, and achieve the effect of simple structure, few parts and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

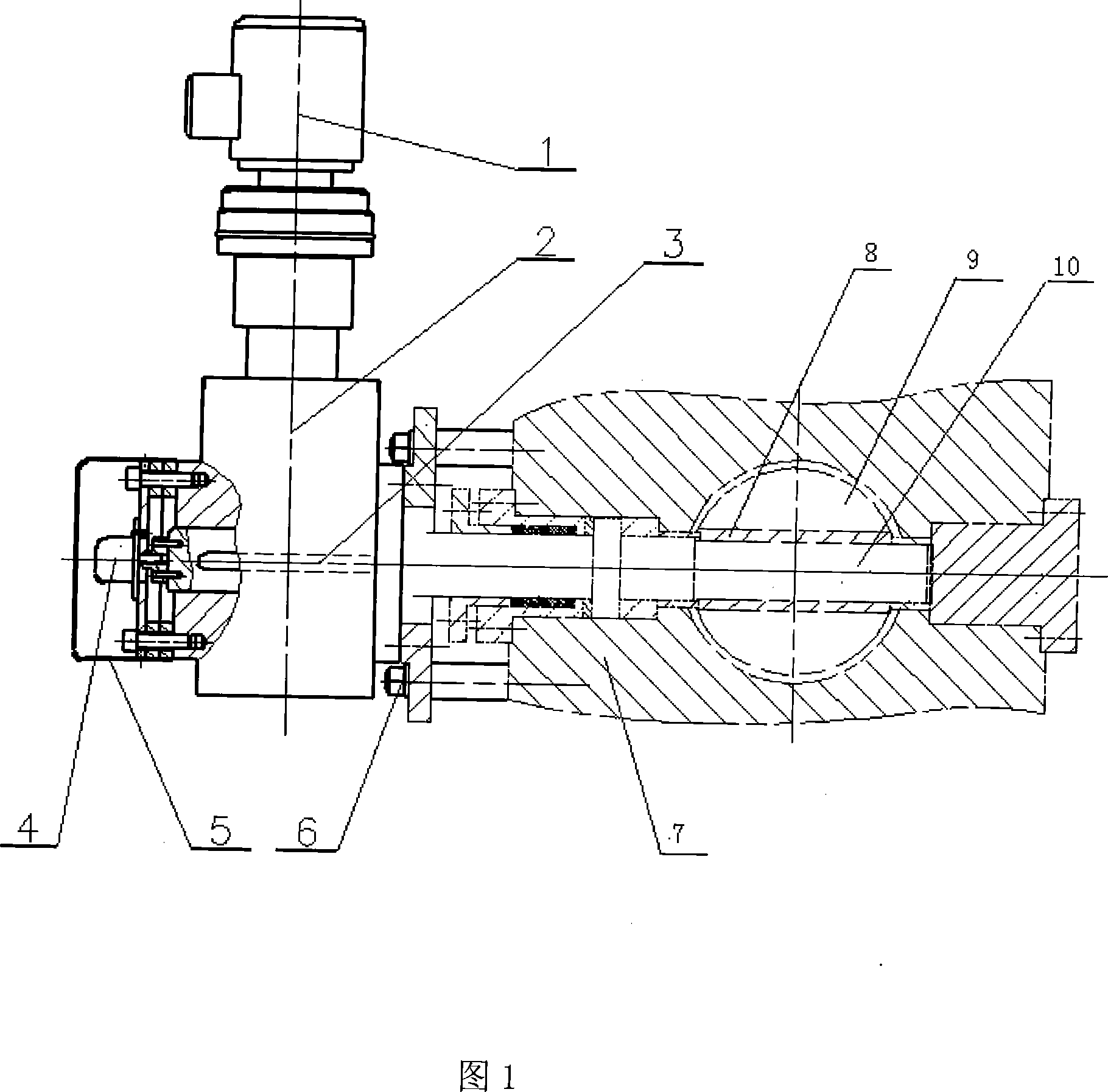

[0013] As shown in Figure 1, the driving mechanism of the melt mixing degree adjustment device of the mixing and granulation unit, the adjustment device is provided with a material flow channel 9 in the valve body 7, and the material flow channel is equipped with a rotatable valve whose flow area varies with the rotation angle. Different spools 8 or valve plates, the spools or valve plates are connected to the driving mechanism through the rotating mechanism, the driving mechanism is the output shaft of the motor 1 and the reducer 2, the reducer is a worm gear reducer, the reducer and the melt The rotating shaft 10 of the mixing degree adjusting device is connected by the key 3, the valve body and the reducer are connected by the fastener 6, etc., the end of the rotating shaft is equipped with an angular displacement sensor 4, the signal of the angular displacement sensor is input to the motor controller, and the angular displacement sensor is set Inside the protective cover 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com