Numerical control precise four-stage rolling mill for ore screen machining

A continuous rolling mill and mining screen technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of raw metal wire shaking, affecting rolling quality, raw material wire falling on the ground, etc., to achieve guaranteed The effect of one-way rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

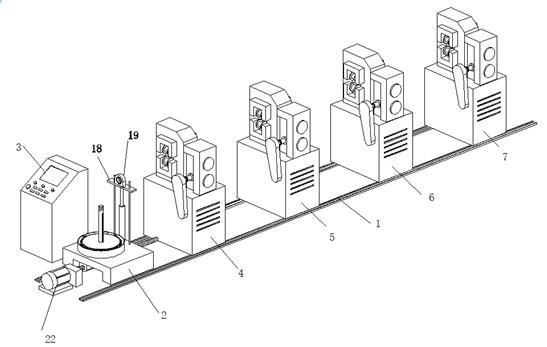

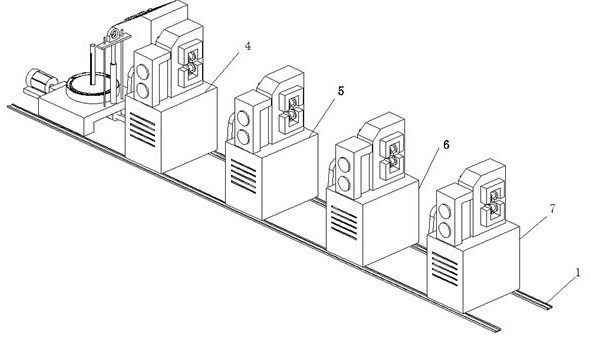

[0033] A kind of numerical control precision continuous rolling mill for mine screen processing, such as Figure 1-Figure 6As shown, it includes rail 1, wire rack 2 and electrical control cabinet 3, and the upper end of rail 1 is installed with wire rack 2, first-stage rolling mill 4, second-stage rolling mill 5, third-stage rolling mill 6 and fourth-stage rolling mill in sequence from left to right 7. Both the first-stage rolling mill 4 and the third-stage rolling mill 6 are horizontal transmission rolling mill units, the second-stage rolling mill 5 and the fourth-stage rolling mill 7 are both vertical transmission rolling mill units, the first-stage rolling mill 4, the second-stage rolling mill 5, the third-stage rolling mill 6 and The structures of the four-stage rolling mill 7 are all the same and are existing equipment, and the rolling mill is mainly composed of a roll, a frame, a roll gap adjustment device, a roll temperature adjustment device, a transmission device, a lu...

Embodiment 2

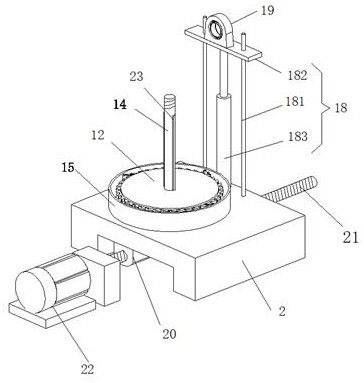

[0039] Embodiment 2 is on the basis of embodiment 1, as figure 1 and image 3 As shown, the height adjustment assembly 18 is also installed on the upper end of the wire drawing frame 2. The height adjustment assembly 18 includes a guide rod 181, a supporting plate 182 and an electric cylinder 183. A pair of guide holes are provided on the surface of the supporting plate 182, and the supporting plate 182 is slidably installed at the same time. On the outer wall of a pair of guide rods 181 , the center position of the bottom end surface of the support plate 182 is fixed to the telescopic end of the electric cylinder 183 , and the electric cylinder 183 is electrically connected with the electric control cabinet 3 .

[0040] Embodiment 2 During the rolling process, the electric cylinder 1 can be controlled by the electric control cabinet 3 to extend or shorten, thereby driving the supporting plate 182 to move upward or downward for a certain distance, and the top of the height adj...

Embodiment 3

[0042] Embodiment 3 is on the basis of embodiment 2, as figure 1 and Figure 8 As shown, the top of the height adjustment assembly 18 is fixed with a guide wire assembly 19, and the guide wire assembly 19 includes a guide wire seat 191, a guide sleeve 192, a cage 193 and a ball 194, and the guide wire seat 191 has a circular ring inside the guide wire seat 191. The hole 195, the inside of the round hole 195 is covered with a guide sleeve 192, and a number of ball mounting holes are formed inside the cage 193. The cage 193 is fixed inside the annular space formed between the round hole 195 and the guide sleeve 192, and inside the cage 193 Several balls 194 are installed in rotation.

[0043] Embodiment 3 During the rolling process, the raw metal wire will pass through the inside of the guide sleeve 192, and the setting of the ball 194 enables the guide sleeve 192 to rotate along the inside of the wire guide seat 19, so that the raw metal wire is more smooth when conducting. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com