Fixed enzyme membrane reactor, preparation thereof and method for producing biological diesel oil by the same

A technology of membrane reactors and immobilized enzymes, applied in the direction of enzyme production/bioreactors, fixed on/in organic carriers, biological raw materials, etc., can solve the problems of reducing catalytic efficiency, easy inactivation of enzymes, and increasing production costs and other issues, to achieve the effect of improving catalytic efficiency, increasing the amount of enzyme loaded, and facilitating diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

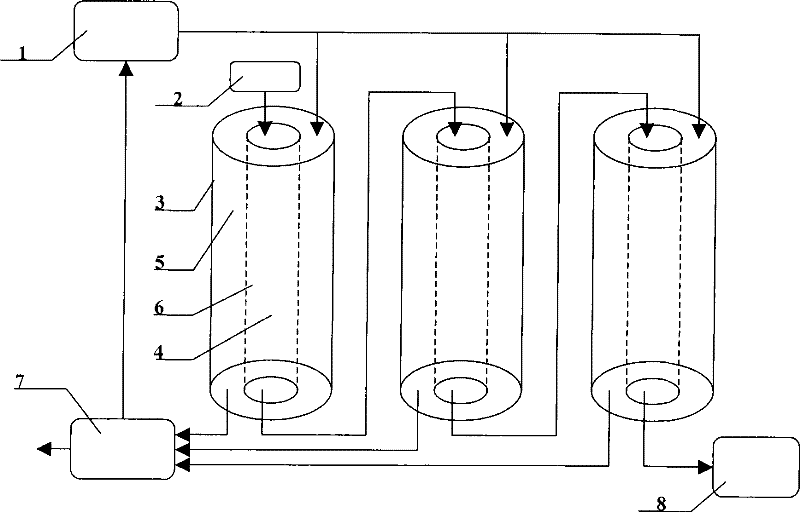

[0029] The acrylonitrile / 2-methacryloyloxy-ethyl-phosphatidylcholine / hydroxyethyl methacrylate terpolymer with a molecular weight of 200,000 is dissolved in dimethylformamide to form a concentration of 4wt.%. spinning solution. Under the conditions of spinning voltage of 7kV, spinneret solution flow rate of 0.1mL / h, and receiving distance of 8cm, electrospinning was carried out to make ultrafine fiber composite membrane with fiber diameter of 1000nm, and polyester non-woven fabric was used as support material. Fill it in the inner and outer double cylindrical membrane tool to form a membrane reaction device ③, as shown in the attached figure, the inner cylinder of the membrane device is called the inner side of the membrane device membrane ④, and the cavity between the inner and outer cylinders is It is called the outer side of the membrane of the membrane device ⑤. Three membrane devices are connected in series to form the first, second and third membrane reactors. Using cr...

Embodiment 2

[0031] The acrylonitrile / 2-methacryloyloxy-ethyl-phosphatidylcholine / hydroxyethyl methacrylate terpolymer with a molecular weight of 150,000 is dissolved in dimethylformamide to form a concentration of 5wt.%. spinning solution. Under the conditions of spinning voltage of 8kV, spinneret solution flow rate of 1mL / h, and receiving distance of 10cm, electrospinning was carried out to make ultrafine fiber composite membrane with fiber diameter of 500nm, and polyester non-woven fabric was used as support material. It is filled in a roll-type membrane, and multiple membranes are connected in series to form a first-, second-, and third-stage membrane reactor. Using cross-flow filtration, first circulate epichlorohydrin in the membrane reactor device at 27°C for 1.5 hours, and then circulate the lipase solution with a concentration of 8g / L in the membrane reactor device at 27°C 1.5 hours; during the circulation process, both epichlorohydrin and lipase solution enter the inner side of ...

Embodiment 3

[0033] The acrylonitrile / 2-methacryloyloxy-ethyl-phosphatidylcholine / hydroxyethyl methacrylate terpolymer with a molecular weight of 100,000 is dissolved in dimethylformamide to form a concentration of 4wt.%. spinning solution. Under the conditions of spinning voltage of 10kV, spinneret solution flow rate of 2mL / h, and receiving distance of 25cm, electrospinning was carried out to make ultrafine fiber composite membrane with fiber diameter of 200nm, and polyester non-woven fabric was used as supporting material. It is filled in a roll-type membrane tool, and multiple membrane tools are connected in series to form the first, second and third-stage enzyme membrane reactors. Using cross-flow filtration, first circulate epichlorohydrin in the membrane reactor device at 25°C for 2 hours, and then circulate the lipase solution with a concentration of 10g / L in the membrane reactor device at 25°C 2 hours; during the circulation process, the epichlorohydrin and lipase solution enter t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com