Method for removing radionuclide by using nano Fe3O4-CeO2 material

A fe3o4-ceo2, radionuclide technology, used in radioactive purification, nuclear engineering and other directions, can solve the problems of low anti-pollution ability, short service life, poor thermal stability and other problems, achieve easy recovery, difficult desorption, adsorption reaction mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] nano Fe 3 o 4 -CeO 2 Materials used for adsorptive removal of simulated radionuclides 90 Sr and 60 Co, the steps are as follows: a reagent bottle with a volume of 20mL is used as a reactor, and waste water containing radionuclides contains Sr 2+ and Co 2+ solutions, including single nuclide systems and Sr 2+ and Co 2+ Coexisting multi-nuclide system, the pH is not adjusted (5.5-5.8), add nano-Fe at an amount of 0.6g / L to 15mL of waste water containing radionuclides 3 o 4 -CeO 2 For materials, the reactor was sealed and then placed in a desktop constant temperature shaking incubator for reaction at a speed of 150 rpm and a temperature of 30°C. Equilibrium adsorption amount after 8h reaction (q e ) See Table 1:

[0021] Table 1 Nano Fe 3 o 4 -CeO 2 Material Removal Radionuclide Results Data Sheet

[0022] system

[0023] Detection method: After the sample is filtered through a 0.22m microporous membrane, the initial and remaining Sr is detected by...

Embodiment 2

[0025] nano Fe 3 o 4 -CeO 2 The material is used to adsorb and remove the simulated radionuclide Sr 2+, the steps are as follows: a reagent bottle with a volume of 20mL is used as a reactor, and 15mL of Sr 2+ Wastewater solution, then add nano Fe in an amount of 0.6g / L 3 o 4 -CeO 2 For materials, the reactor was sealed and then placed in a desktop constant temperature shaking incubator for reaction at a speed of 150 rpm and a temperature of 30°C. Equilibrium adsorption capacity (q e ) see Table 2:

[0026] Table 2 Nano-Fe at different pH 3 o 4 -CeO 2 Material removal nuclide Sr 2+ Result data table

[0027] pH

[0028] Detection method: with embodiment 1.

Embodiment 3

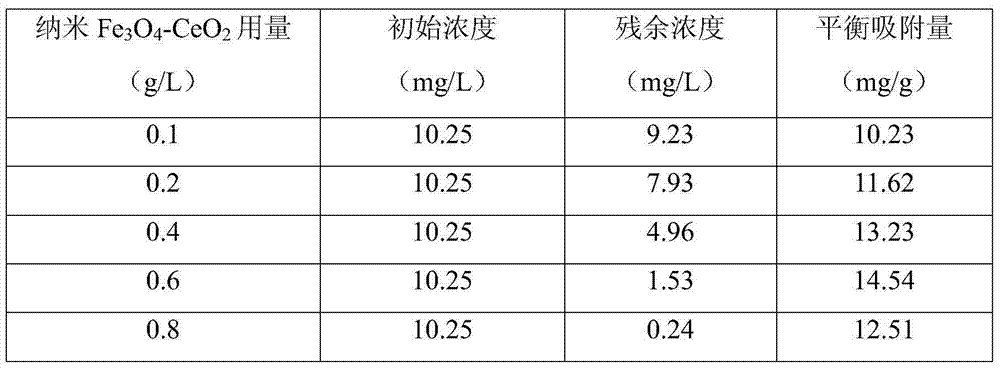

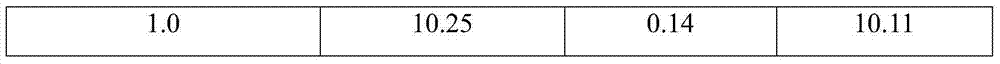

[0030] nano Fe 3 o 4 -CeO 2 Materials used for adsorptive removal of simulated radionuclide Co 2+ , the steps are as follows: a reagent bottle with a volume of 20mL is used as a reactor, and 15mL of Co 2+ Wastewater solution and nano-Fe 3 o 4 -CeO 2 Material, pH is 5.5, the reactor is sealed and placed in a desktop constant temperature shaking incubator for reaction, the rotation speed is 150 rpm, and the temperature is 30°C. different nano Fe 3 o 4 -CeO 2 Equilibrium adsorption amount (q e ) See Table 3:

[0031] Table 3 Different nano-Fe 3 o 4 -CeO 2 Nuclide Co 2+ The removal results data table for

[0032]

[0033]

[0034] Detection method: with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com