Acid gas adsorbent as well as preparation method and application of acid gas adsorbent

A technology of acid gas and adsorbent, which is applied to the adsorbent that can absorb acid gas. In the field of preparation of the above-mentioned adsorbent, it can solve the problems of not being able to remove harmful gases well, and achieve low cost of use, simple steps, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

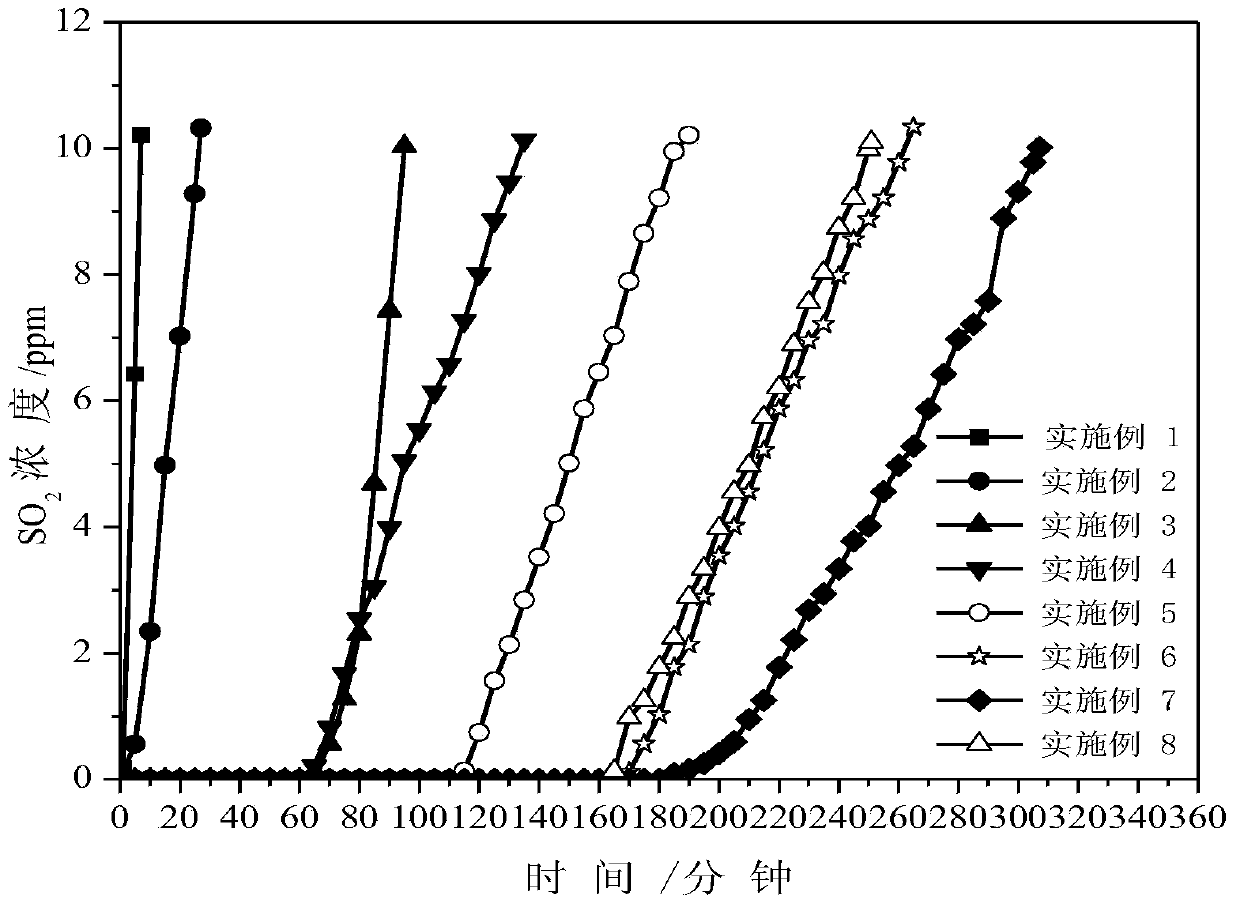

Examples

Embodiment 1

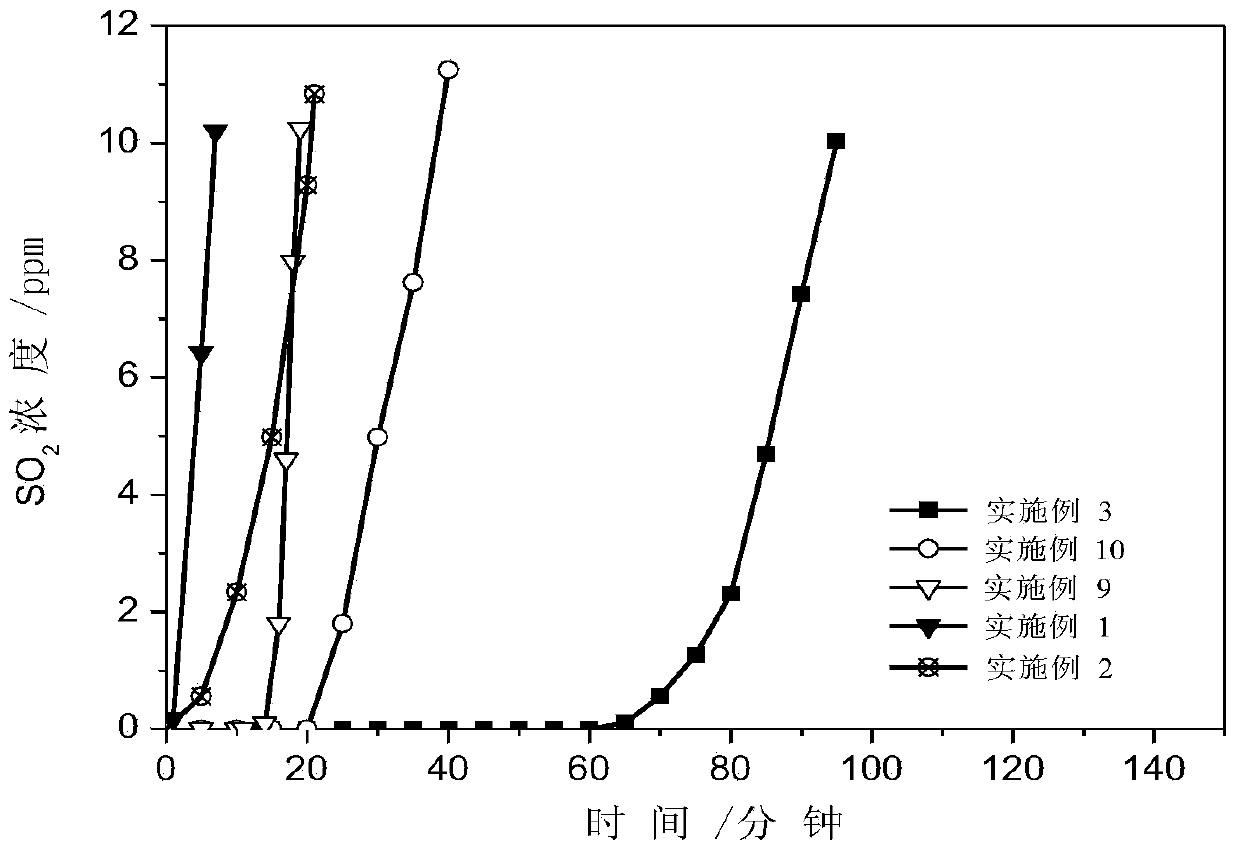

[0031] Embodiment 1 (comparison)

[0032] Firstly, the spherical 5A zeolite is ground into powder, and then sieved through a 200-mesh standard sieve to obtain powder 5A zeolite.

Embodiment 2

[0034] Firstly, the spherical 5A zeolite is ground into powder, and then sieved through a 200-mesh standard sieve to obtain powder 5A zeolite. Ammonia water: cetyltrimethylammonium bromide (CTMAB): 5A zeolite: ethyl tetrasilicate=9:3:3:5-10 (wt%). Ammonia water (25wt%) was added into 200 ml of deionized water, and ultrasonicated for 15 minutes. Then CTMAB was slowly added to the ammonia solution and sonicated for 15 minutes. Then, the powder 5A zeolite was slowly added into the mixture of ammonia water and CTMAB, and ultrasonically oscillated for 15 minutes. Transfer the zeolite and the mixed solution to a constant temperature magnetic stirrer and stir for 15 minutes. Under the stirring state, add tetraethyl orthosilicate dropwise to the mixed solution. After constant stirring for 2 hours, the mixed solution is filtered, washed, dried, Roasting (at a temperature of 550°C) etc. to obtain a support (ie modified 5A zeolite MZs, the ratio of silica to 5A zeolite is 1:1). Its sp...

Embodiment 3

[0036]The carrier was prepared as described in Example 2. Measure TEA and dissolve it with deionized water; add 1g of MZs to the TEA aqueous solution and oscillate ultrasonically for 15 minutes; then heat and stir at a constant temperature of 70°C until the water in the mixture evaporates to dryness; dry the solid in a blast drying oven at 30°C After 6 hours, a TEA / MZs adsorbent with a weight ratio of 0.2:1 was prepared (ie, the weight ratio of triethanolamine to carrier was 0.2:1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com