Food processing machine with current limiting net

A food processing machine, current limiting technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problem of incomplete crushing effect, and achieve the effect of simple structure, long service life and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

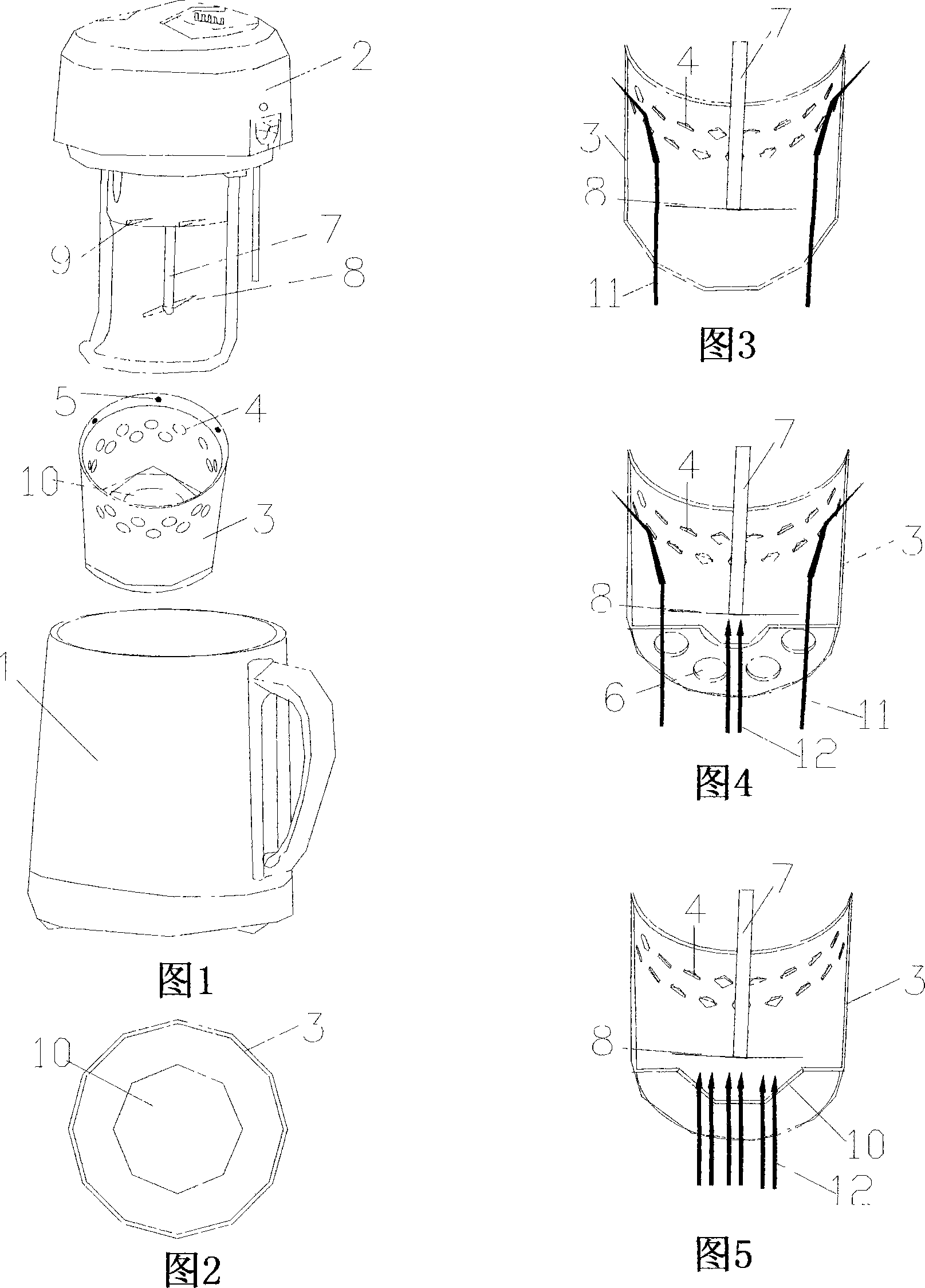

[0021] A food processing machine with a flow-limiting net, as shown in Figure 1 and Figure 2, includes a cup body 1 and a machine head 2, the machine head 2 is installed above the cup body 1, and the long axis of the motor installed in the machine head 2 Blade 8 is fixed on the front end of 7, and the limited flow net 3 is fixed by draw-in groove 9 and chuck 5 on the below of head 2. The upper half of the current-limiting net 3 is provided with a small current-limiting hole 4 and a clip 5 , and a large current-limiting hole 10 is provided at the bottom of the current-limiting net. The small restrictor hole 4 and the large restrictor hole 10 are circular. The diameter of the small restrictor hole 4 is φ10mm. The diameter of the large restrictor hole 10 is φ110mm.

Embodiment 2

[0023] Same as embodiment 1, the small flow restriction hole 4 and the large flow restriction hole 6 are polygonal. The diameter of the small restrictor hole 4 is φ8mm. The diameter of the large restrictor hole 6 is φ150mm.

[0024] Working principle: As can be seen from Fig. 3, when the blade 8 rotates, the flow line 11 of the deflector is easy to form convection from around the blade 8, and the crushing effect of the blade 8 is unsatisfactory. As can be seen from Fig. 4, when the blade 8 rotated, the streamline 11 part of the flow divider formed convection from the large shunt hole 6 around the blade 8, and only part of the streamline 12 passed through the blade 8, although the crushing effect was improved, But not quite. It can be seen from Fig. 5 that when the blade 8 rotates, the streamline 12 passes through the blade 8, and the crushing effect is relatively complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com