Sound barrier used for viaduct

A technology for sound barriers and bridges, applied in noise absorption devices, buildings, etc., can solve the problems of heavy construction work, high maintenance costs, and many construction procedures, and achieve cost reduction, maintenance, easy assembly, and high surface finish Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

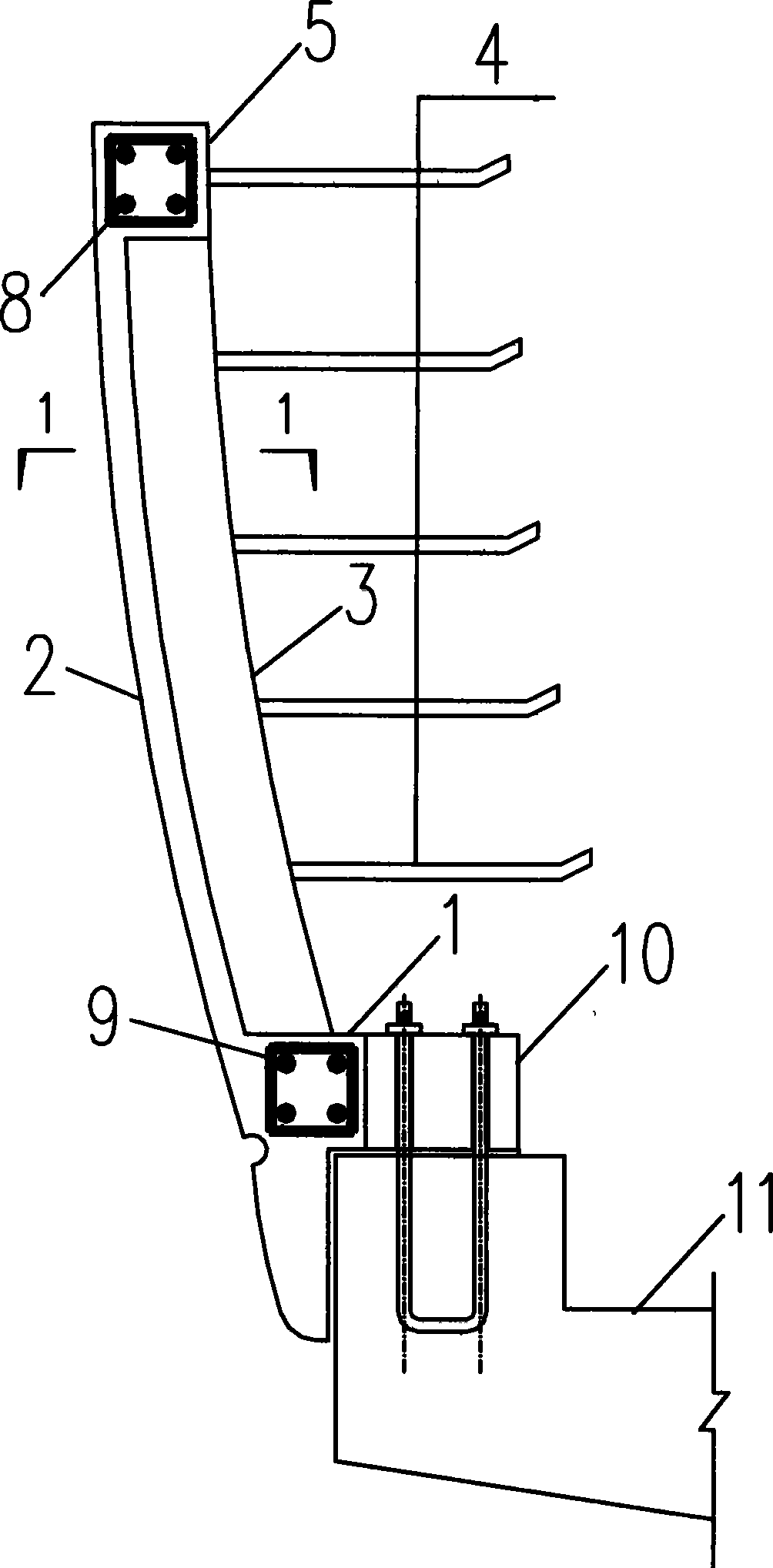

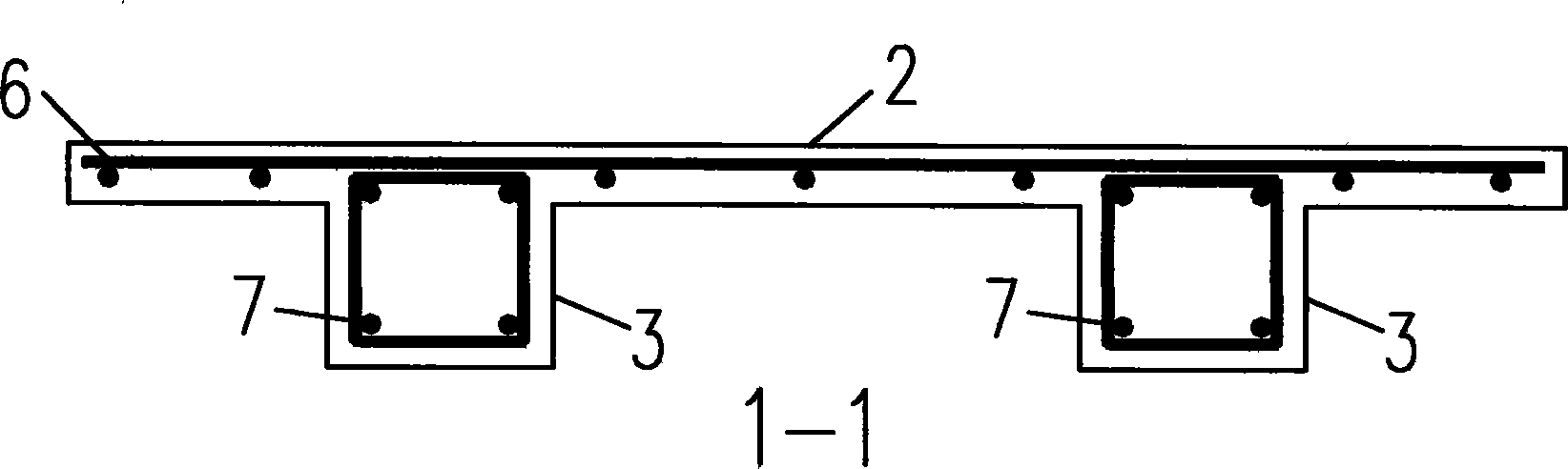

[0027] Below in conjunction with accompanying drawing, the present invention is described in detail, as figure 1 , figure 2 Shown, a kind of composite reinforcement reinforced reactive powder concrete (RPC) used for isolating the noise generated by the subway running on the viaduct, hereinafter referred to as RPC, sound barrier. The sound barrier is made of RPC casting, including the barrier bracket and the cable bracket 4 arranged on the bracket. The bracket includes an integrated prefabricated bottom beam 1, back plate 2 and cross beam 5. The bottom beam 1 is set at the lower end of the back plate 2. The beam 5 is arranged on the upper end of the backboard 2 , and the cable support 4 is arranged on the backboard 2 . For the convenience of positioning and construction during installation, a protruding part is also provided at the lower end of the back plate 2, and the angle between the protruding part and the bottom beam 1 is a right angle, so that the sound barrier can pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com