Single-power bidirectional drilling stirring pile machine

A mixing pile driver and single-power technology, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve the problems of difficult quality assurance, impact on cost performance, and high sealing requirements, so as to ensure the quality of the pile body, long service life, and ensure The effect of pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

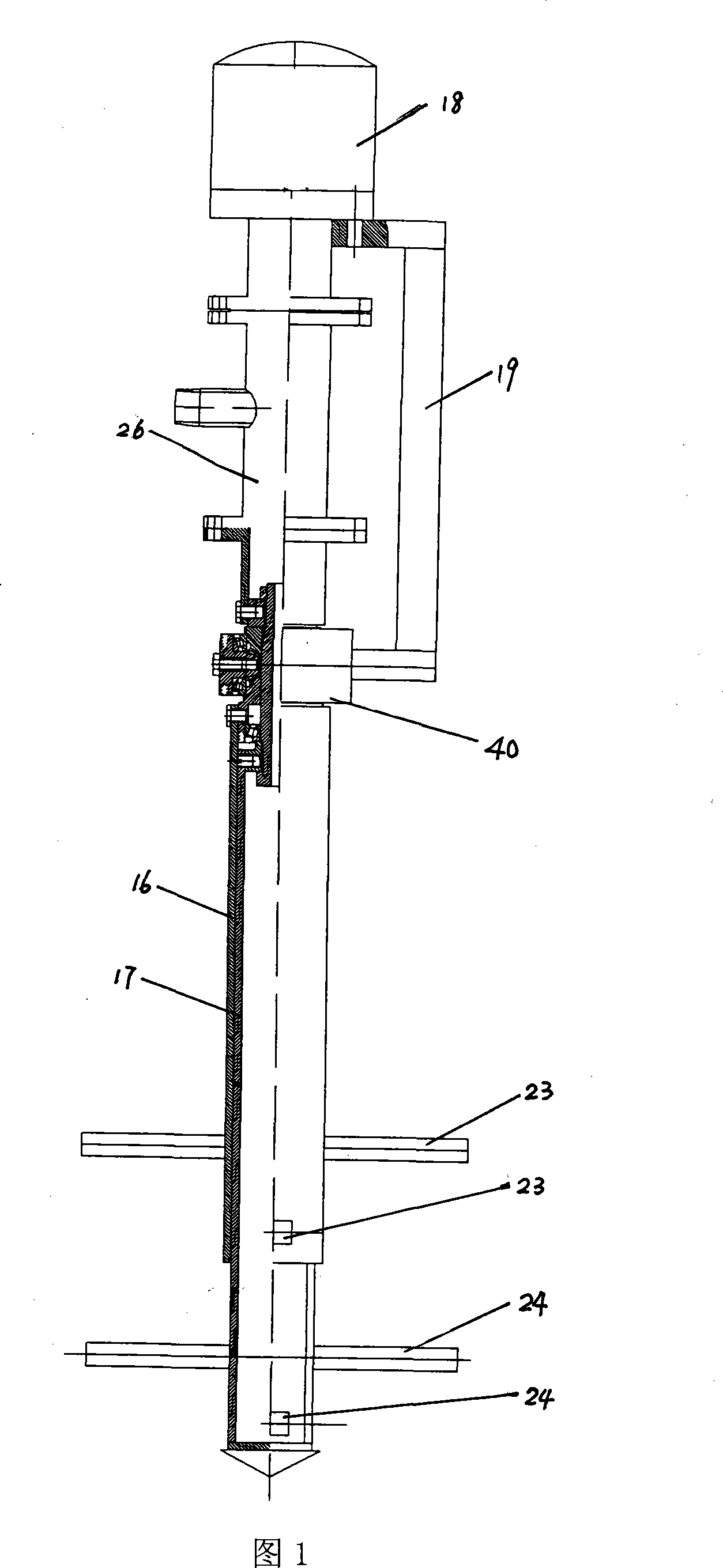

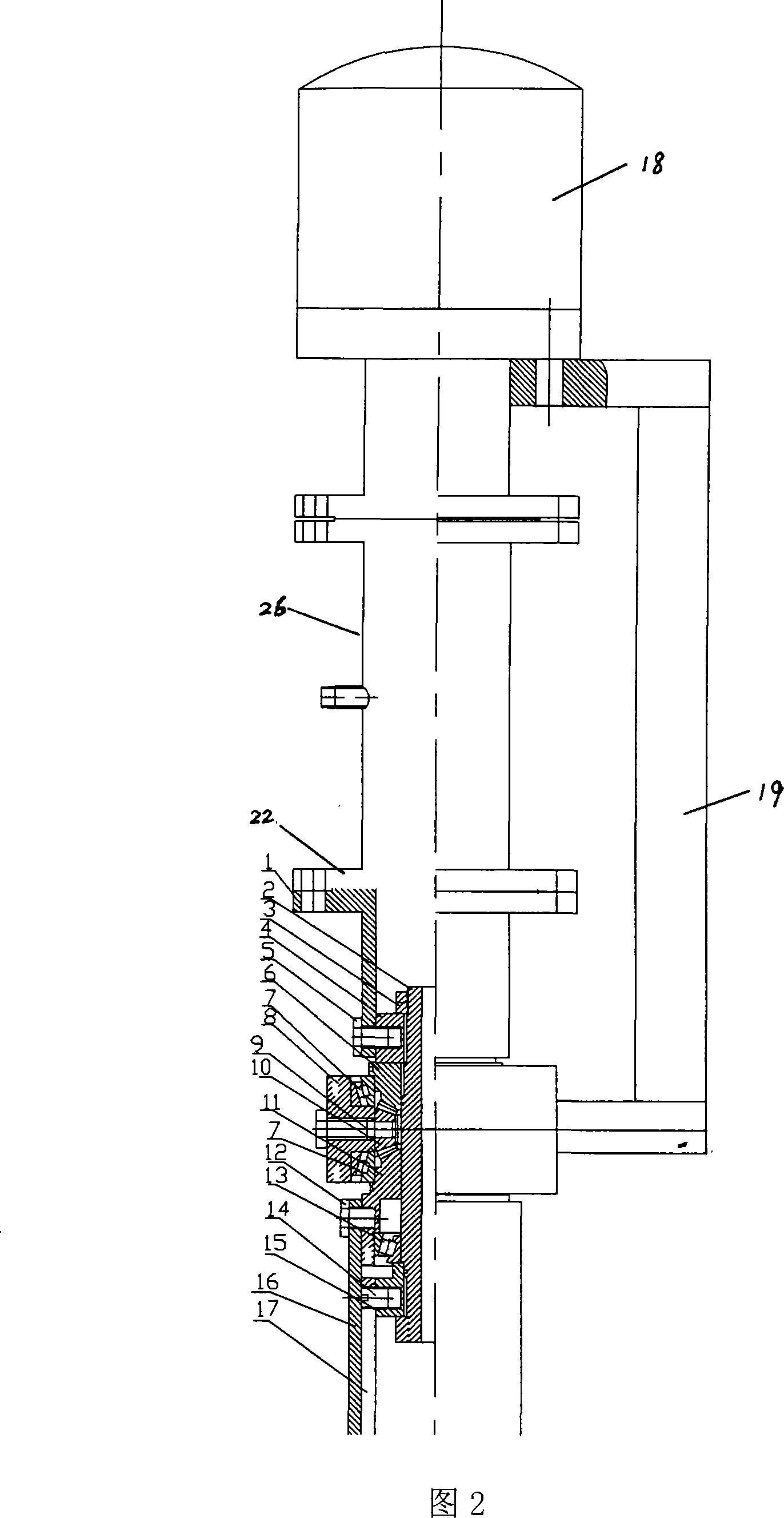

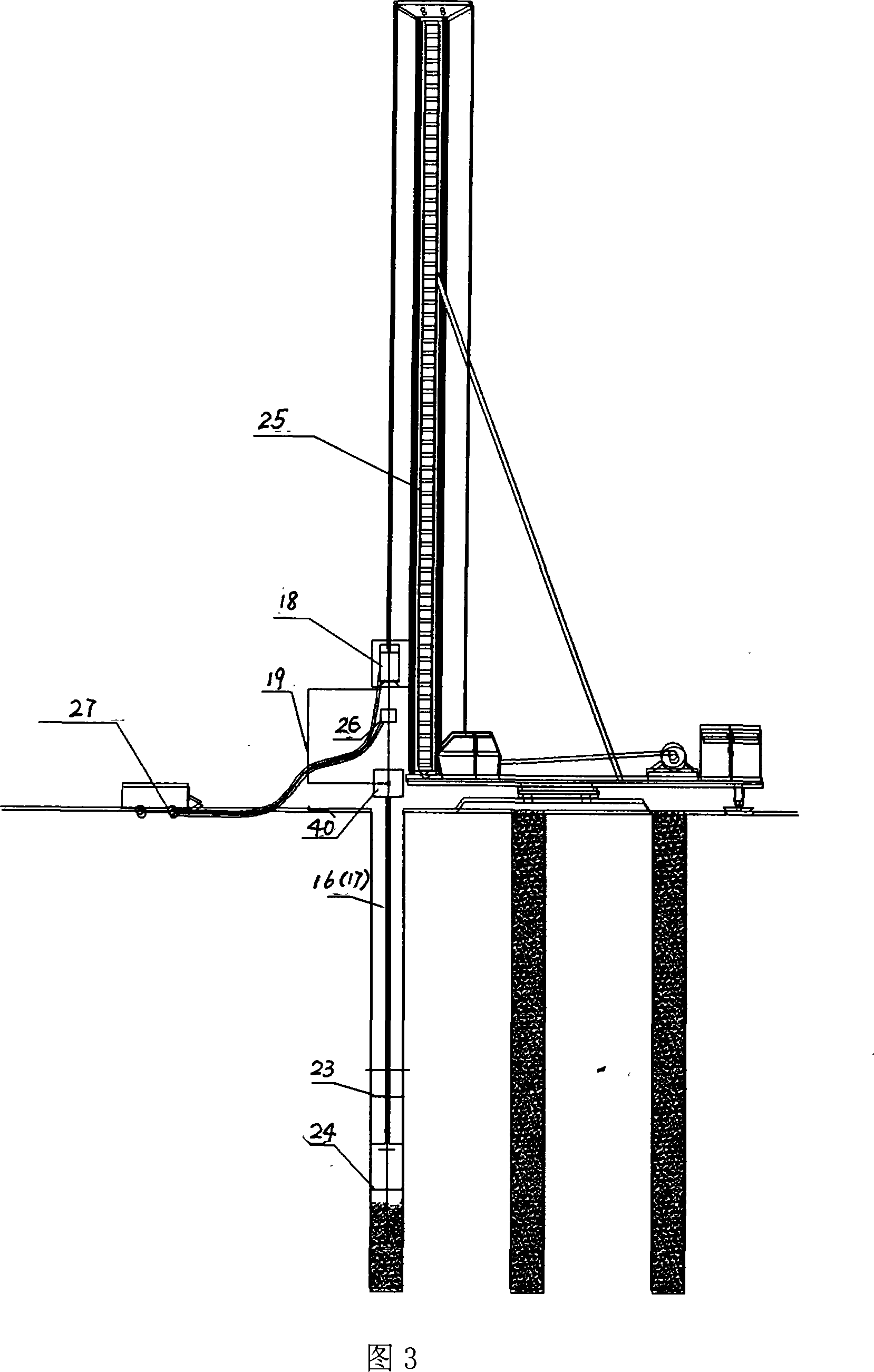

[0021] As shown in Figures 1, 2, and 3, taking a group of 4-layer forward and reverse mixing pile machines as an example, the single-power, two-way drilling mixing pile machine of the present invention includes a forward-rotating drill rod 17 and a reverse-rotating drill rod 16. , motor 18, frame 25, mixing tank and mud pump 27, drill bit blades 23, 24 and the epicyclic gear train mechanism 40 that changes the direction of rotation of the forward drill rod 17 and the reverse drill rod 16, and the epicyclic gear train mechanism 40 is positioned at the drill rod The top, makes the epicyclic gear train become the fixed plate 19 of the fixed axle gear train and is fixed on the motor 18 seat of the stirring pile driver top that does not rotate with motor 18.

[0022] The fixed plate 19 can also be fixed on the frame 25 and the water joint 26 that do ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com