LED mine lamp using non-imaging optical system

A non-imaging optics, LED miner's lamp technology, applied in the field of miner's lamp, can solve the problem of unsatisfactory light distribution effect, achieve good visual effect, improve the utilization rate of light energy, and the effect of accurate illuminance distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

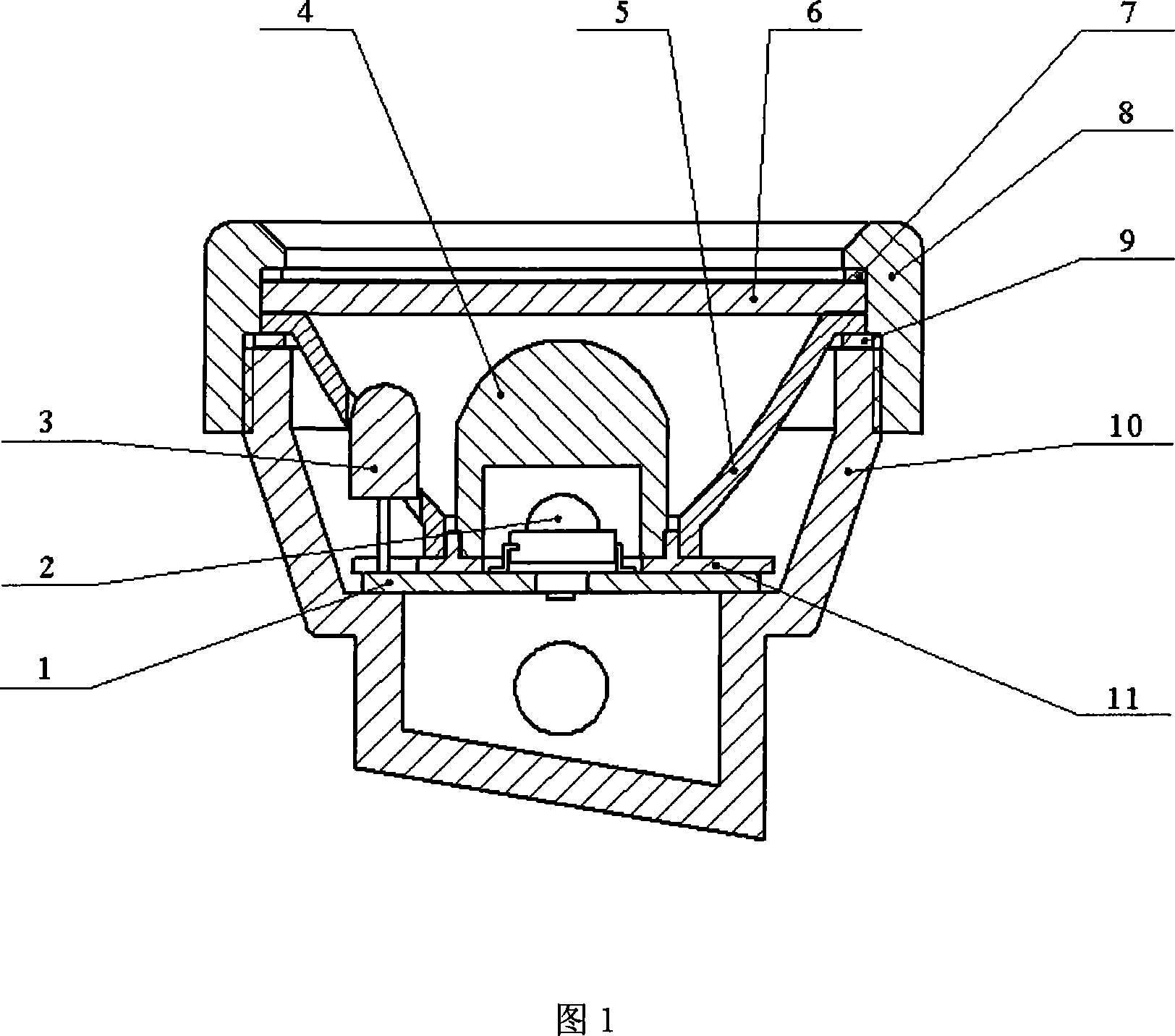

[0013] As shown in Figure 1, the LED miner's lamp using a non-imaging optical system is composed of a non-imaging optical system, a housing component and a lighting circuit component. Wherein, the non-imaging optical system comprises an aspheric compound lens 4, a free-form surface reflector 5 and a base 11, the aspheric compound lens 4 is located in the internal space of the free-form surface reflector 5, the aspheric compound lens 4, the free-form surface reflector 5 They are respectively fixed on the base 11; the lighting circuit components include a high-power LED main light source 2, an auxiliary light source 3 and a circuit board 1, and the high-power LED main light source 2 and the auxiliary light source 3 are respectively welded and fixed on the circuit board 1; the circuit board 1 is located under the base 11 and is connected and fixed together with the base 11, so that the main light source 2 on the circuit board 1 is located in the cylindrical cavity of the aspheric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com