Precasting type repairable low-temperature radiation cool-supply and heating system

A low-temperature radiation and heating system technology, applied in the hot water central heating system, heating system, air conditioning system and other directions, can solve the problems of difficult construction and installation, user misery, limited popularization and promotion, etc., to simplify the on-site construction process , The effect of improving indoor sanitary conditions and saving indoor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

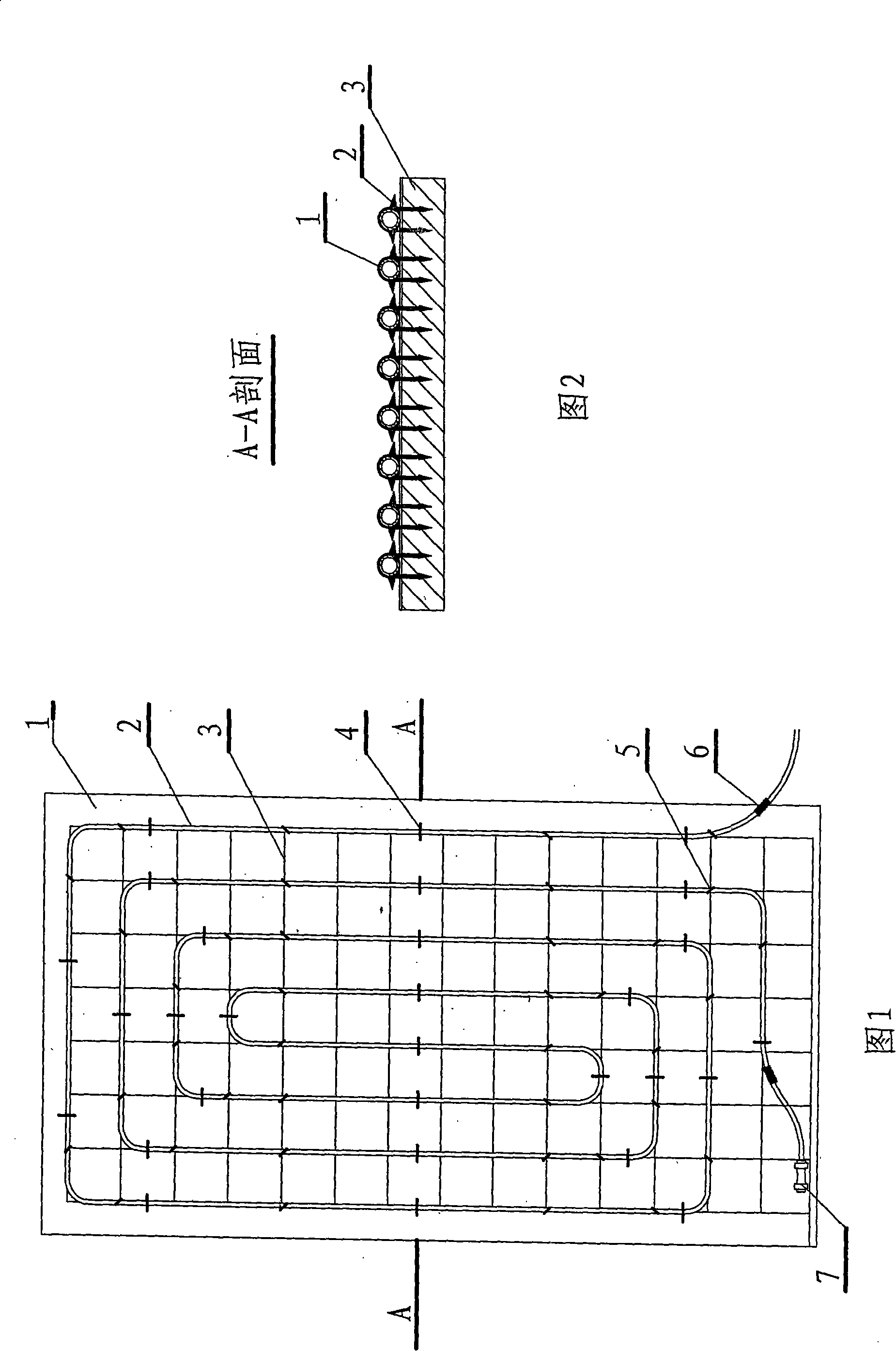

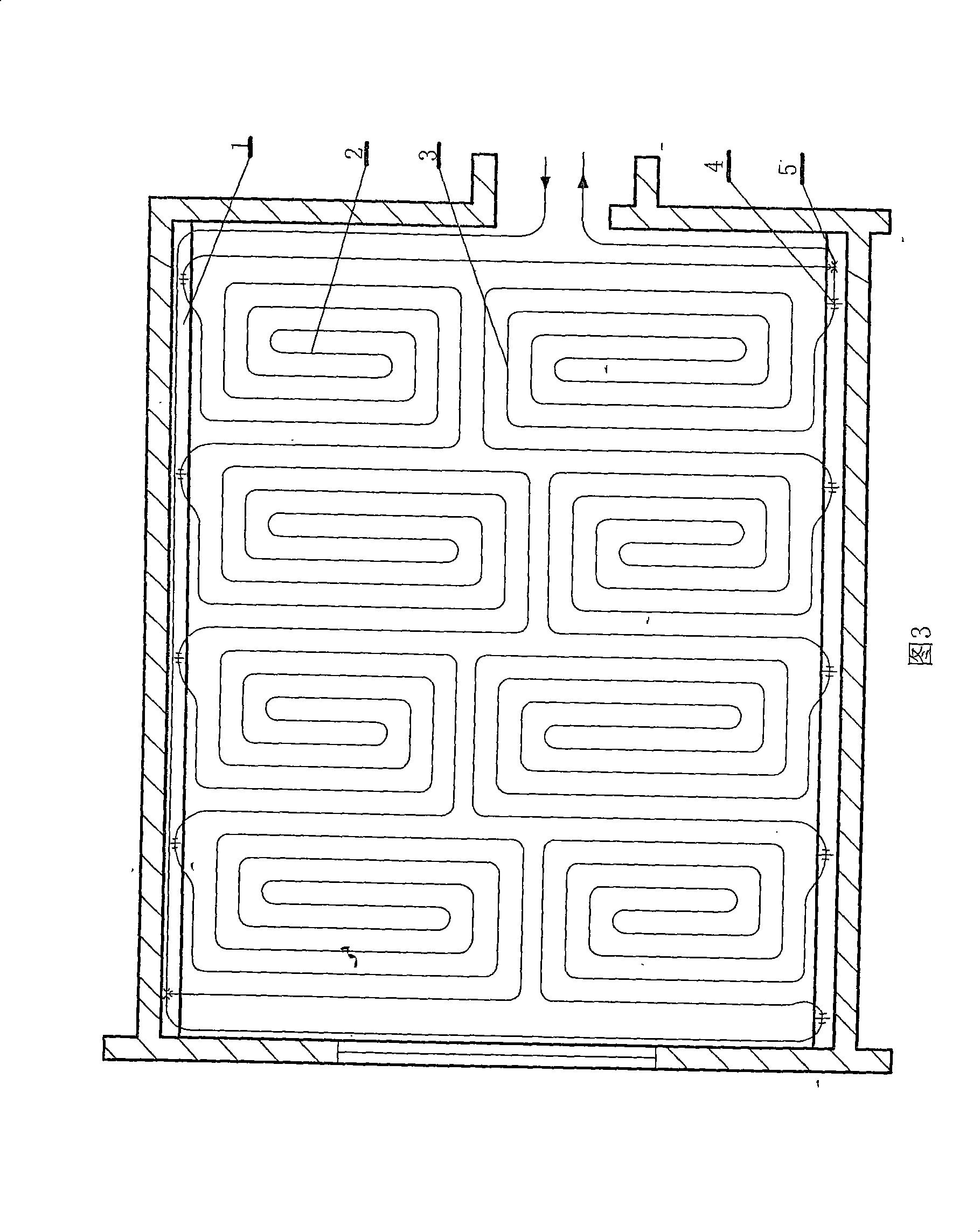

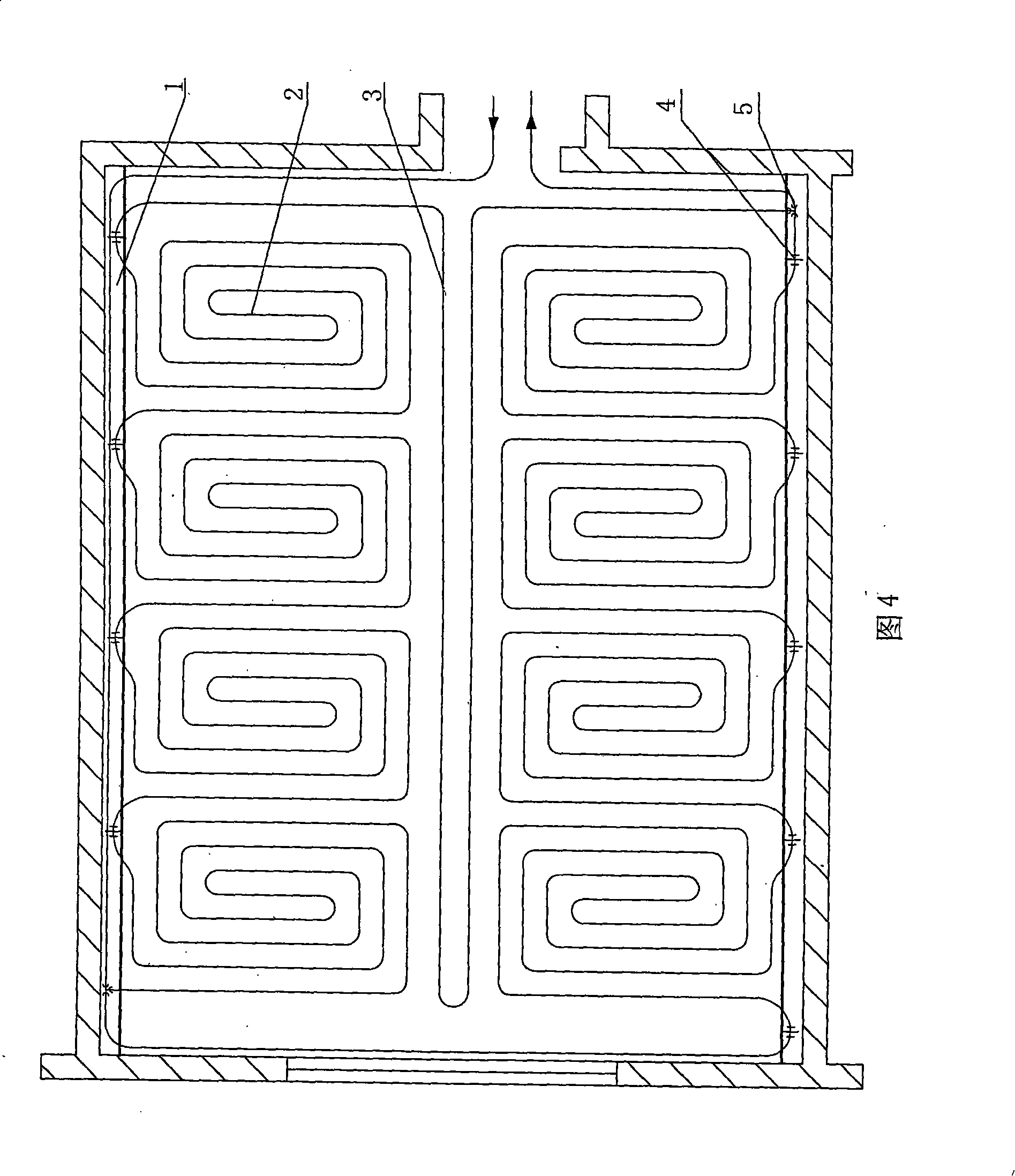

[0023] The installation sequence of the ceiling radiant cooling (warming) system is as follows:

[0024] 1. Use expansion bolts to fix the wooden square keel on the ceiling at intervals of 30cm, and level it.

[0025] 2. Fasten the prefabricated unit on the wooden keel with special self-tapping nail tube clips. The distance between the pipe staples is about 30cm.

[0026] 3. In the maintenance groove reserved on both sides of the ceiling of the room, connect the connecting pipe fittings with each prefabricated unit, and conduct a hydraulic test.

[0027] The test pressure is the working pressure at the top of the system + 0.2MPa, and the test pressure at the top of the system is not less than 0.4MPa.

[0028] 4. After passing the hydrostatic test, the pressure in the system continues to be in the water-filled state of 0.4MPa. Use cement mortar mixed with 107 glue for construction for the first plastering, and the thickness should be controlled at about 1 / 3 of the total thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com