Suspending magnetic stagnant compensation method

A compensation method and magnetic levitation technology, applied in the direction of the magnetic attraction or thrust holding device, electrical components, etc., can solve the problems of asynchronous magnetization and demagnetization, the inability to ensure that the suspended object returns to the equilibrium position, and reduce the stability of the magnetic levitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The method of weighting the control signal that needs to be demagnetized is adopted, that is, the software method.

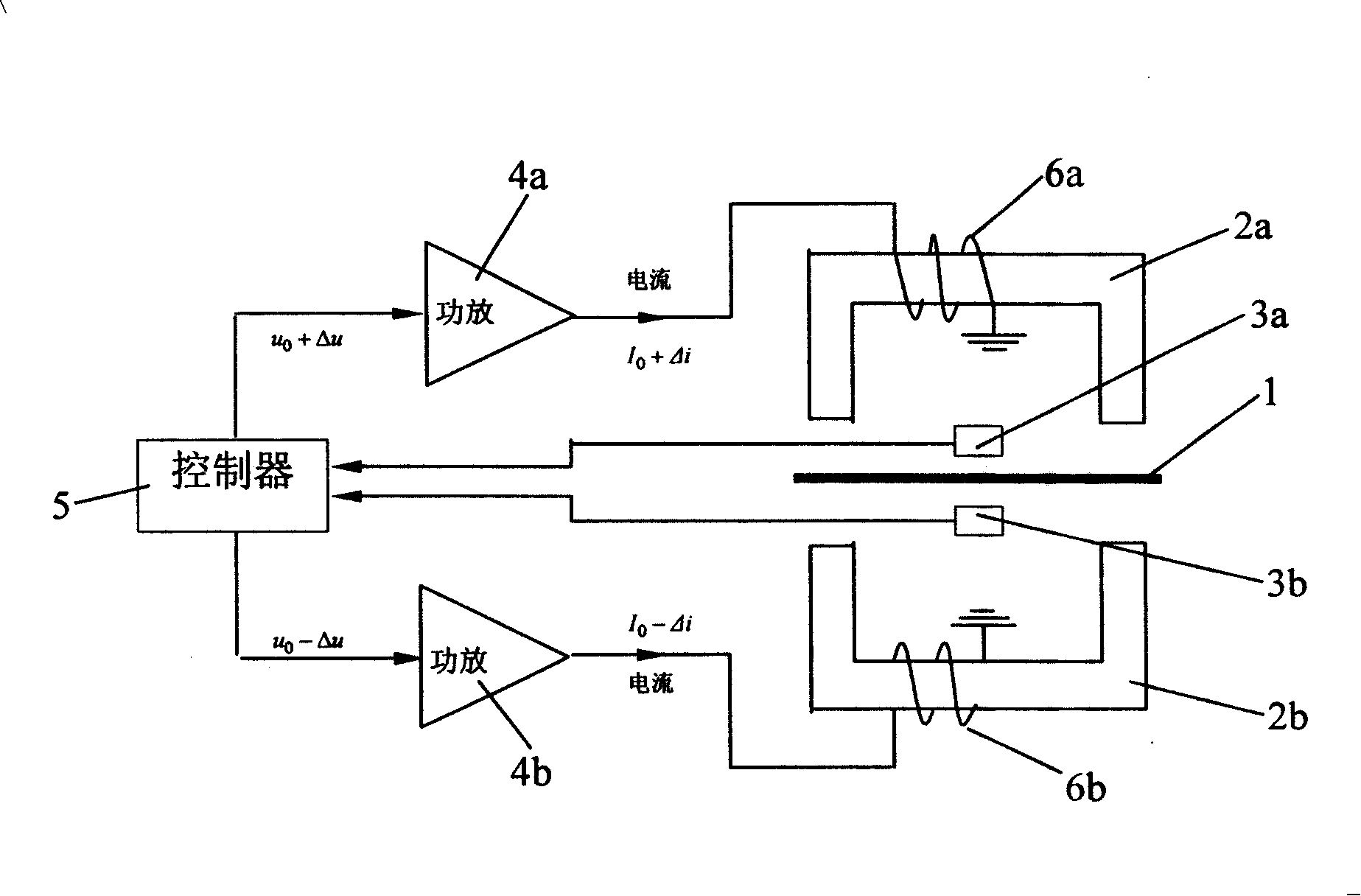

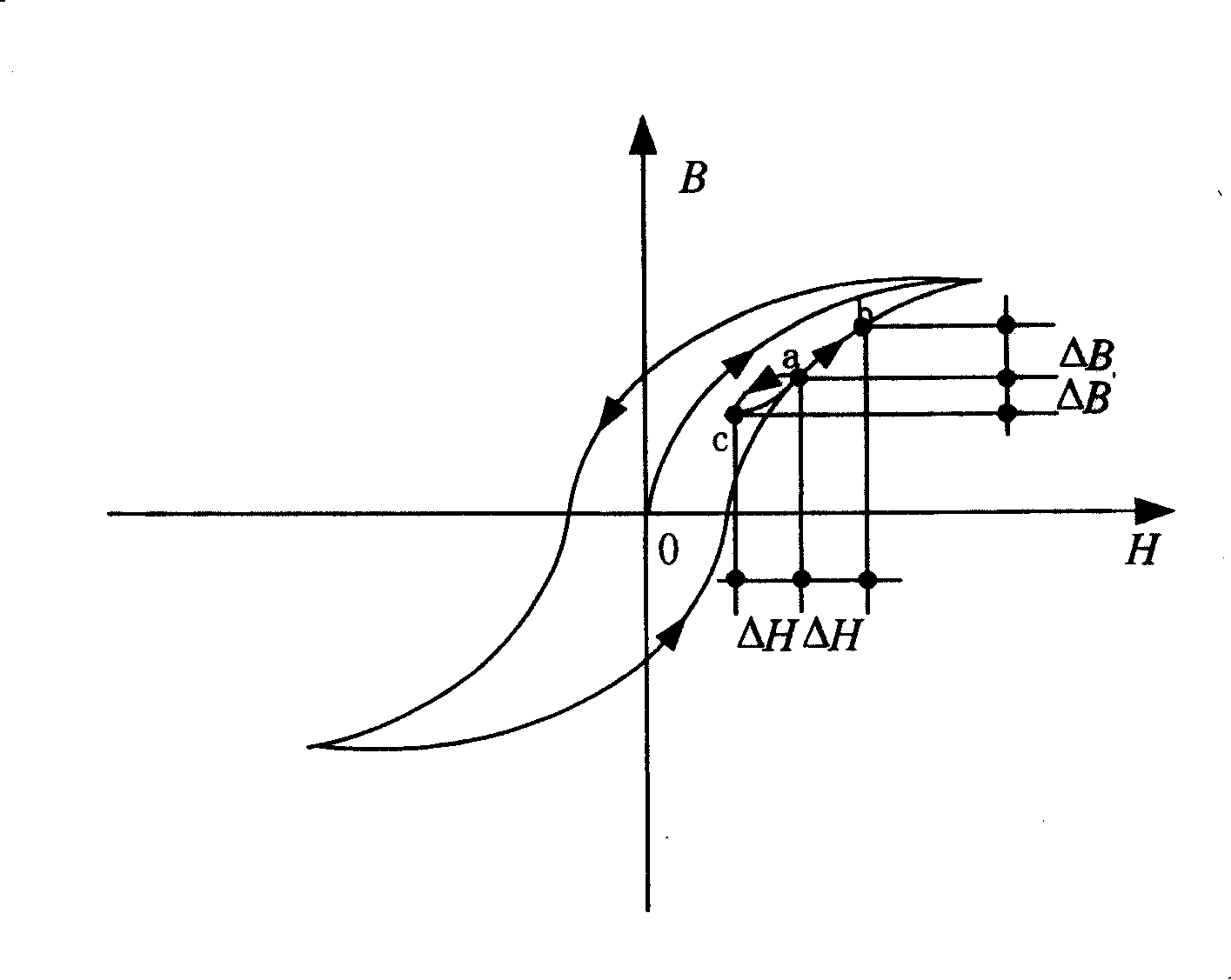

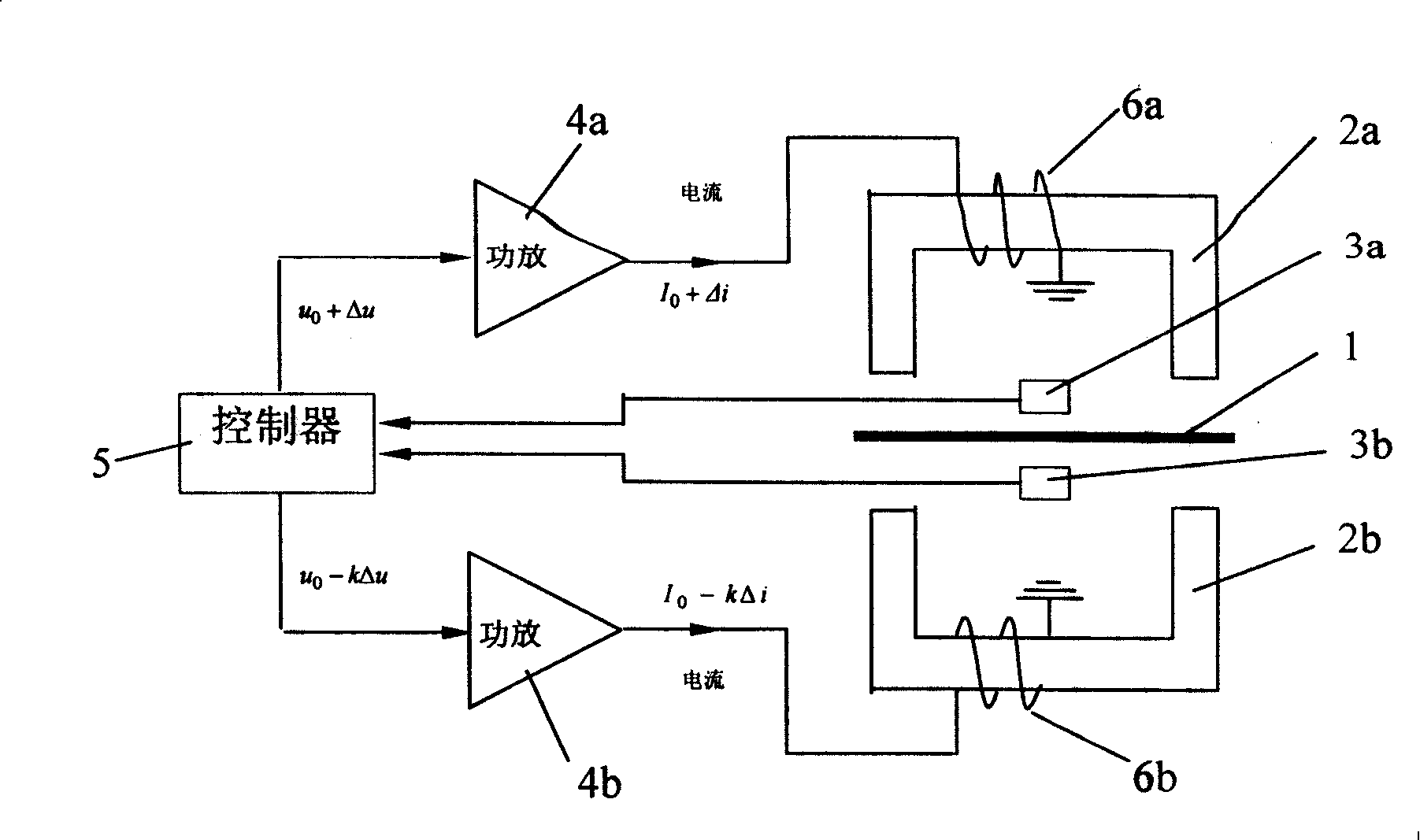

[0048] Please combine image 3 , Figure 4 As shown, when the suspended object 1 deviates from the original equilibrium position under external disturbance, use the sensors 3a and 3b to measure the deviation, and then use the controller 5 to generate a differential control signal (u 0 +Δu) and (u 0 -Δu), from which it is judged that the control signal for demagnetization is (u 0 -Δu), for the control signal (u 0 -Δu) is weighted, multiplied by a weighting factor k to obtain (u 0 -kΔu) control signal, use the power amplifier 4a to control the signal (u 0 +Δu) is converted into the exciting current of coil 6a (I 0 +Δi), use the power amplifier 4b to convert the control signal (u 0 -kΔu) is converted into the exciting current of coil 6b (I 0 -kΔi), please combine with that shown in Figure 5, since the increase Δi of the magnetic induction of the diff...

Embodiment 2

[0050] The method of increasing the compensation current by adding compensation coils and corresponding compensation power amplifiers is the hardware method.

[0051] Please combine with Fig. 6 and Fig. 7, add a compensation coil 7a and a compensation power amplifier 4c corresponding to the compensation coil 7a on the differential electromagnet 2a; Coil 7b correspondingly compensates power amplifier 4d. When the suspended object 1 deviates from the original equilibrium position under external disturbance, use the sensors 3a and 3b to measure the deviation, and then use the controller 5 to generate a differential control signal (u 0 +Δu) and (u 0 -Δu), from which it is judged that the control signal for demagnetization is (u 0 -Δu), the control signal (u 0 +Δu) and (u 0 -Δu) is converted into the excitation current of coils 6a and 6b (I 0 +Δi) and (I 0 -Δi); then use the controller 5 to generate a compensation signal Δu ', use the corresponding compensation power amplifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com