Numerical control groove cut-off apparatus

A bevel cutting and cutting torch technology, applied in the field of CNC bevel cutting devices, can solve the problems of many mechanical rods, large movement space, and easy damage, and achieve the effects of saving production costs and reducing the volume of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

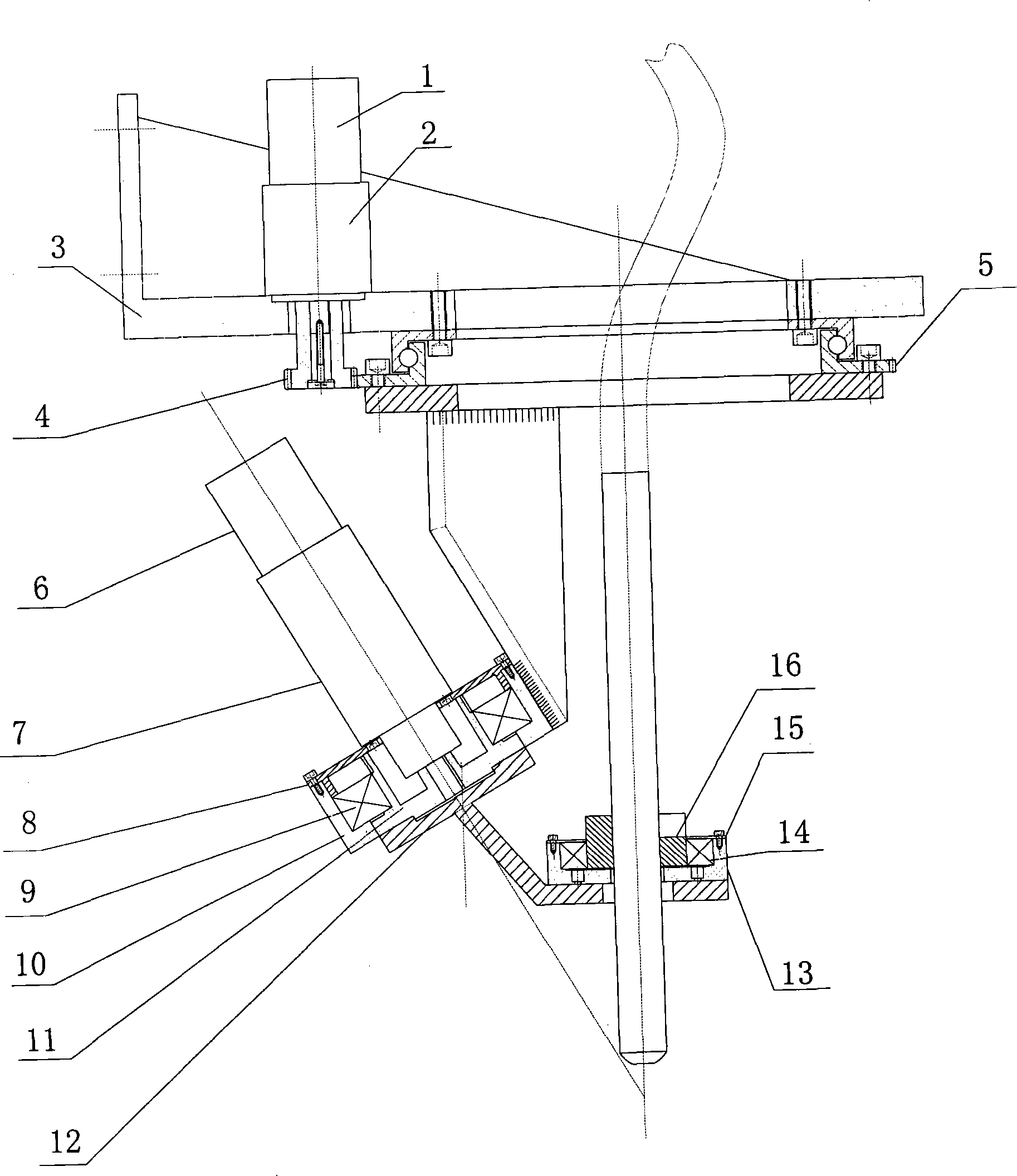

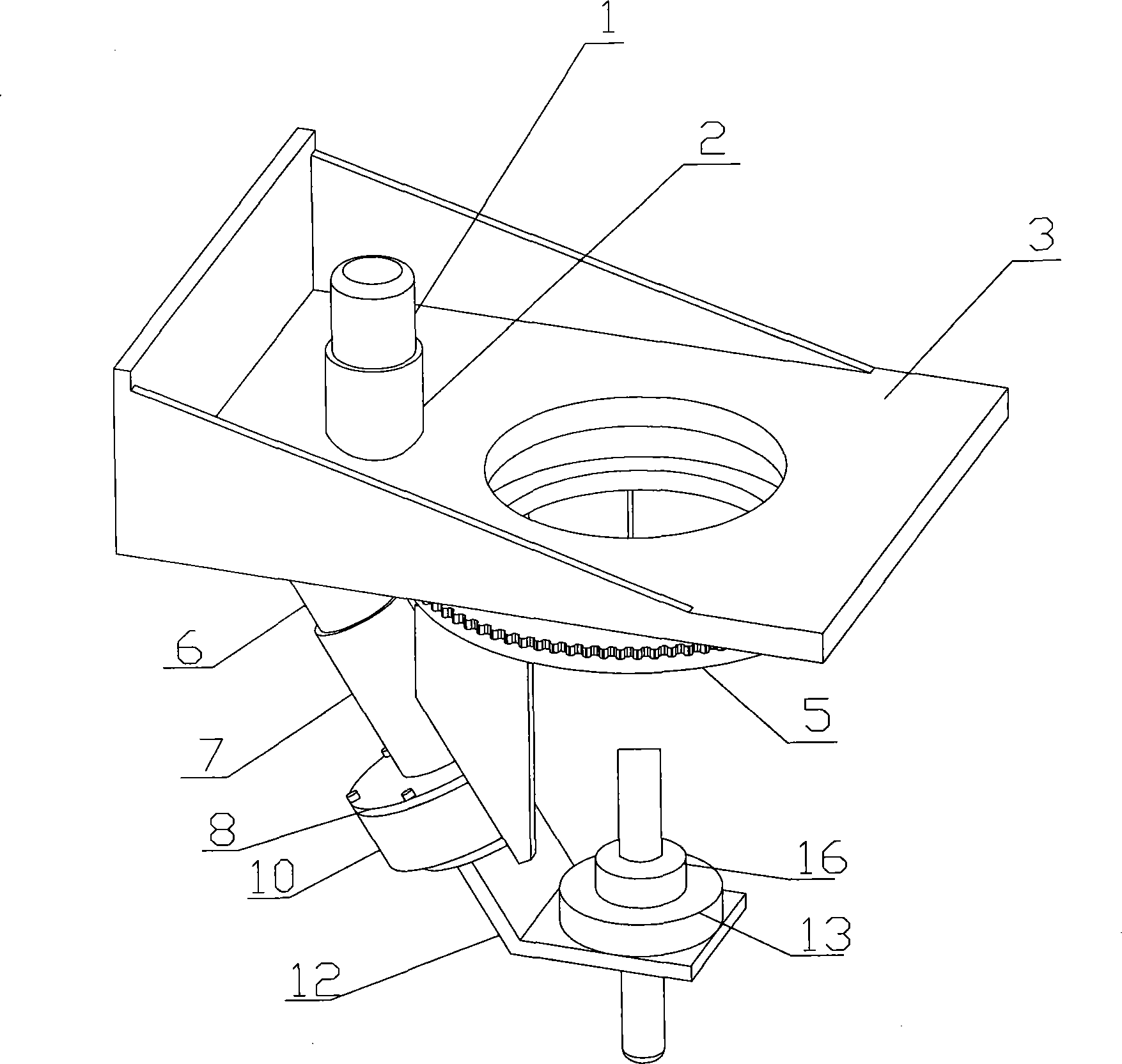

[0014] Such as figure 1 As shown, the bevel cutting device of the present invention is composed of a base 3, a main drive, an auxiliary drive, a torch holder and an external tooth flange bearing 5.

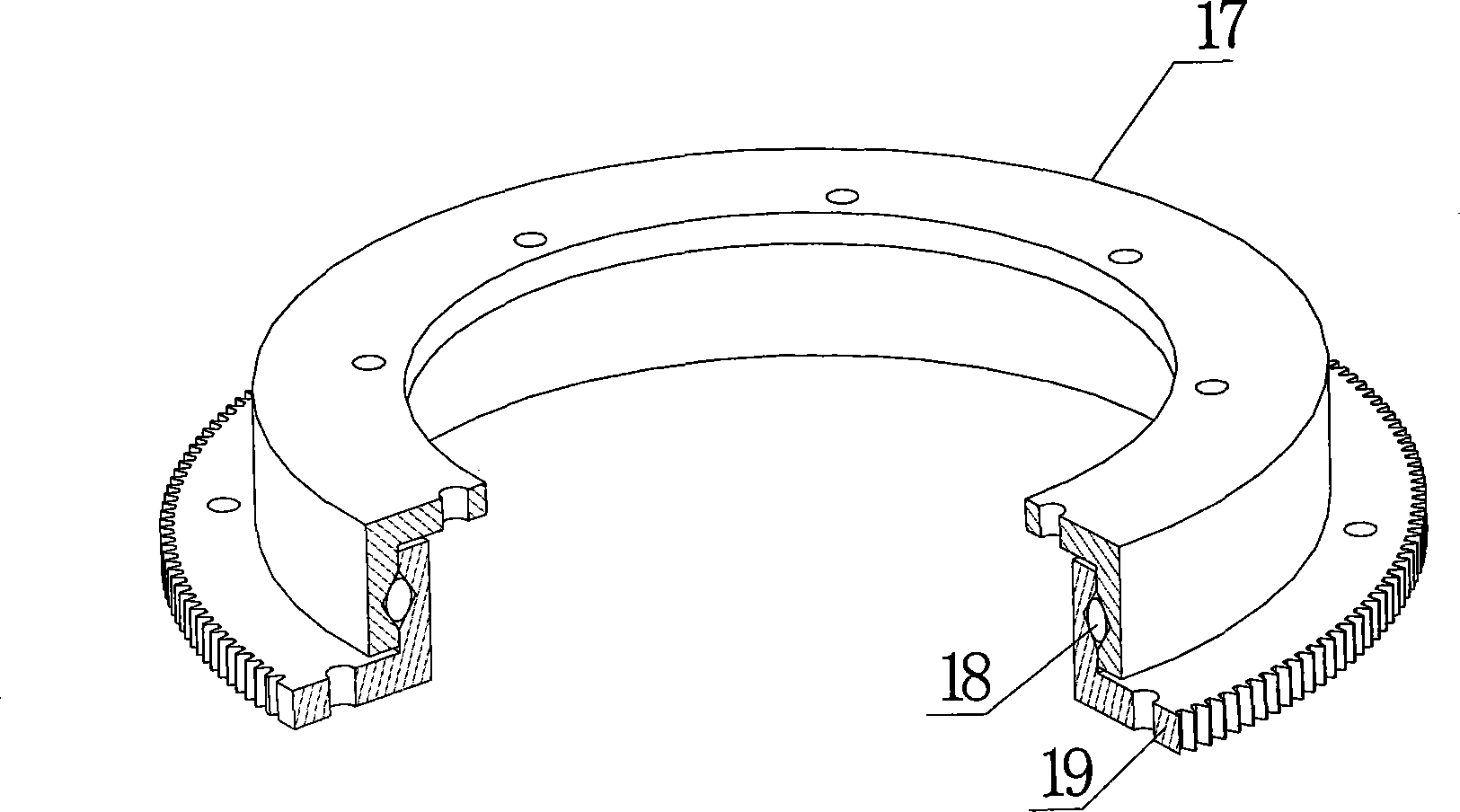

[0015] Among them, the main drive is composed of motor 1, reducer 2 and gear 4. After the motor 1 and the reducer 2 are combined, the pinion 4 is set on the extended shaft end of the reducer. Adjust the center distance between the pinion 4 and the external tooth flange bearing 5, and fix the outer rings of the reducer 2 and the external tooth flange bearing 5 on the base 3 respectively after meshing correctly.

[0016] Such as figure 1 , figure 2 and Figure 4 , Auxiliary drive is made up of motor 6, speed reducer 7, rotating body 10, bearing 9, end bearing cover 8, coupling 11 and angle rotating shaft 12. After the motor 6, the reducer 7 and the shaft coupling 11 are connected and combined, the reducer 7 and the bearing end cover 8 are fixed on the rotating body 10 in seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com