Sanding system of container soldering joint

A container and sand technology, applied in abrasive feeding devices, abrasives, metal processing equipment, etc., can solve the problems of harsh operating environment for workers, unstable system air pressure, high operating costs, and improve workers’ working conditions and energy utilization. The effect of improving the rate and stable sand quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

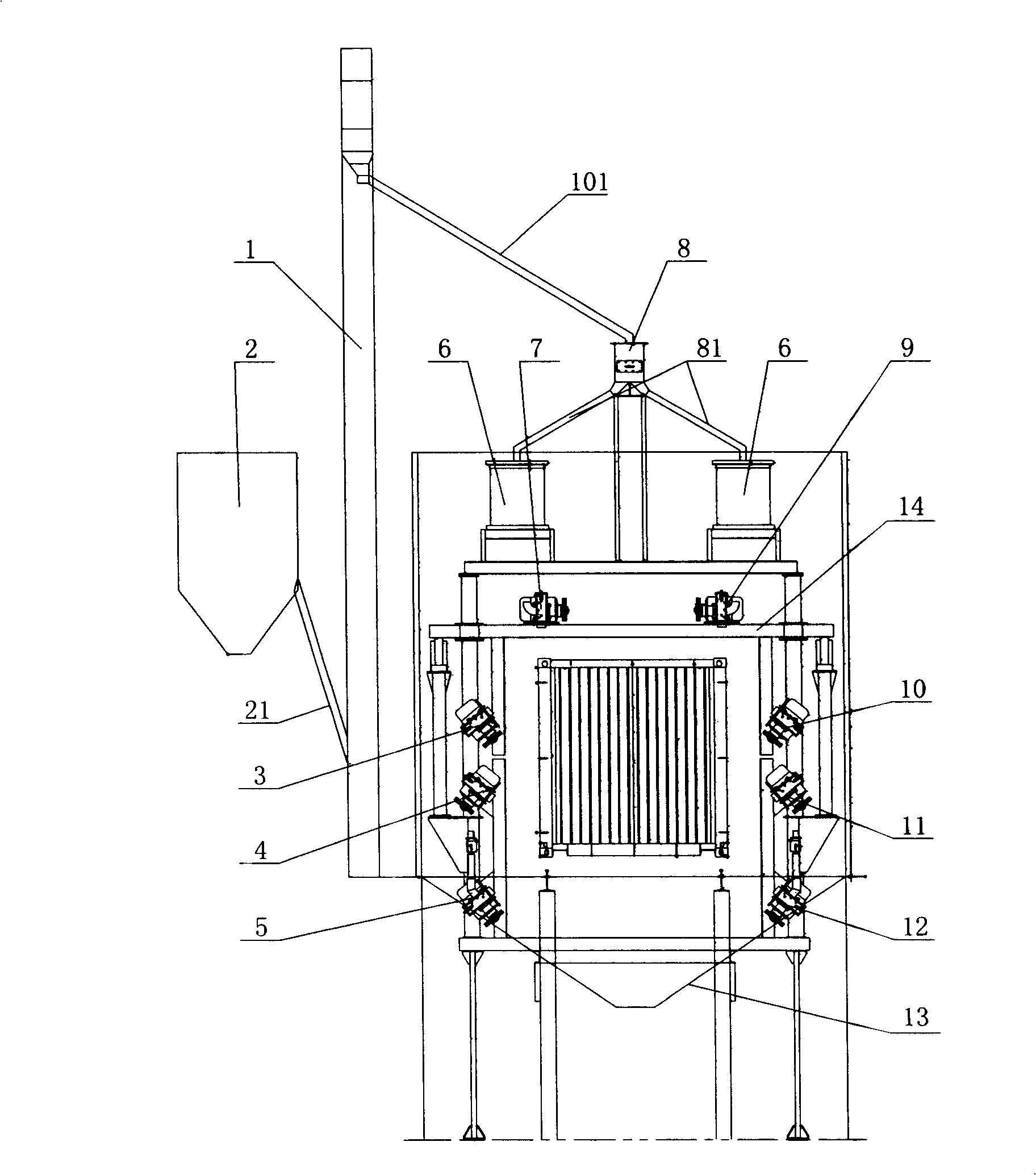

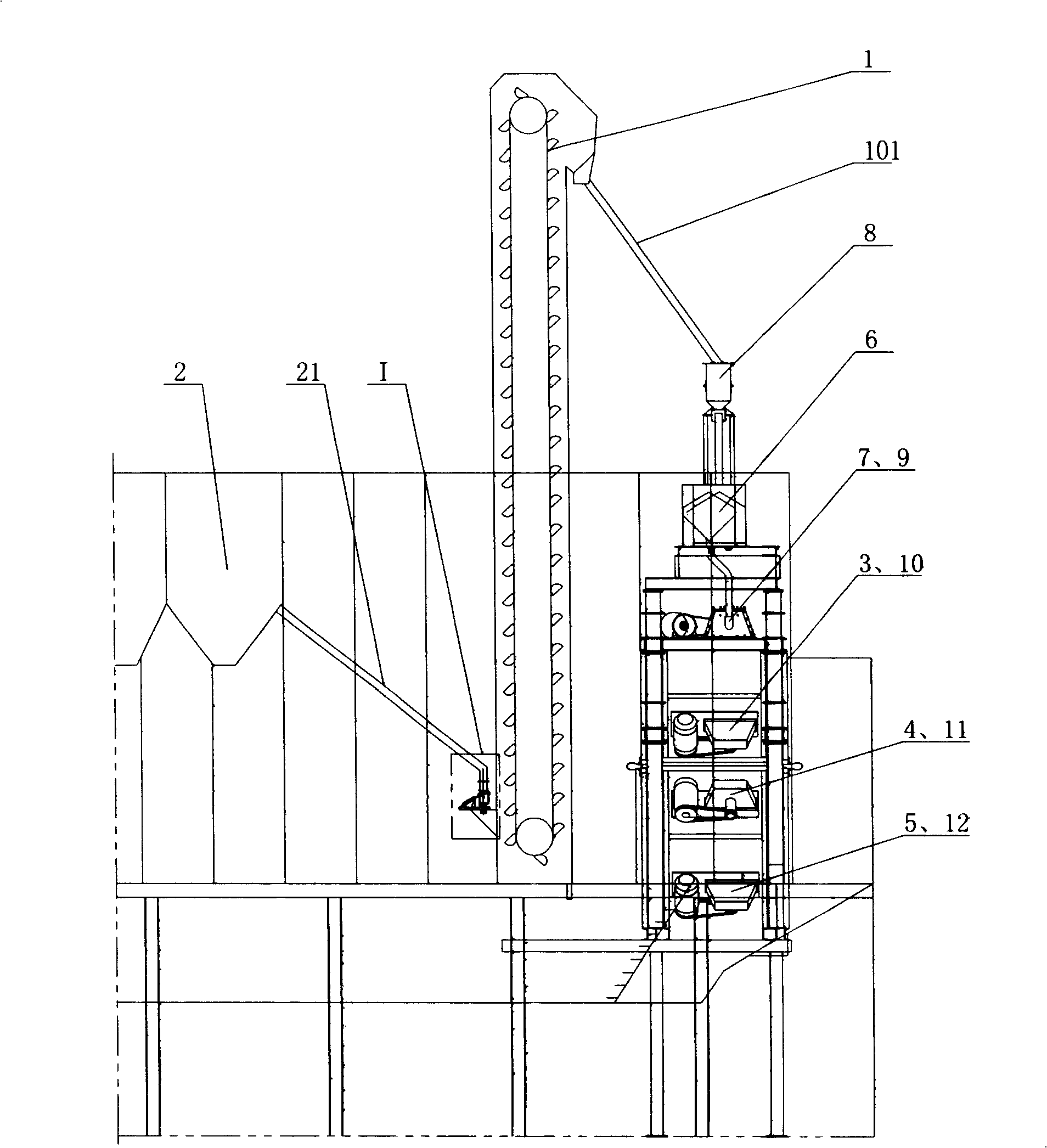

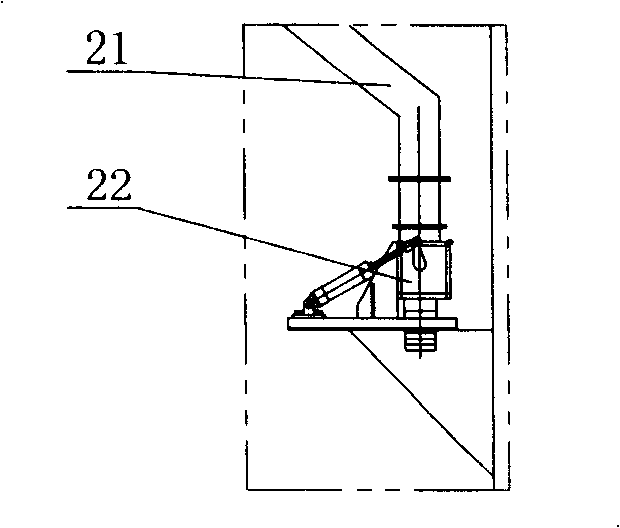

[0025] figure 1 , 2 An embodiment of the container weld seam blasting system of the present invention is shown. Such as figure 1 , figure 2 As shown, the container welding seam blasting system includes a sand conveying section, a sand separating section and a sand blasting section connected in sequence. The sand blasting section includes a door-shaped frame 14 arranged on the container conveying line, electric shot blasting machines 3, 4, 5 and 10, 11, 12 arranged on the structures on both sides of the door-shaped frame 14, and The electric shot blasting machines 7 and 9 on the upper structure, among them, the electric shot blasting machines 7 and 9 process the two welds on both sides of the container top plate and the container top side beam respectively, and the electric shot blasting machines 3, 4, 5 and the electric shot blasting machines Shot blasting machines 10, 11, and 12 respectively process the two welds between the side plate and the top side beam of the contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com