Electromagnetic artificial quartz in lump forming device

An artificial quartz stone and molding device technology, applied in the field of building materials machinery, can solve the problems of small attraction, limited vibration frequency of electromagnets, large electromagnetic power, etc., and achieve the effects of reasonable structure, good pressing and forming effect, and improved compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

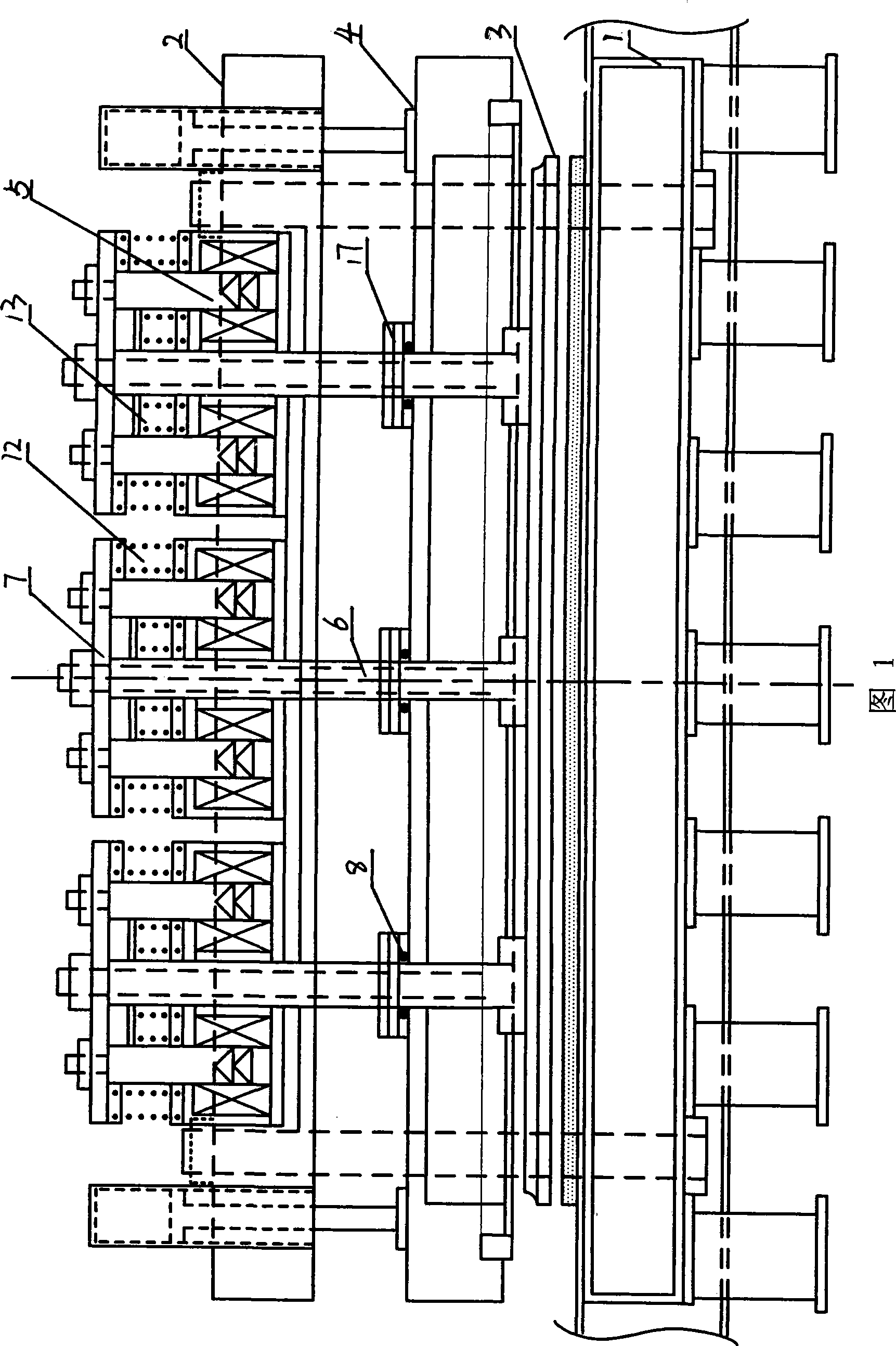

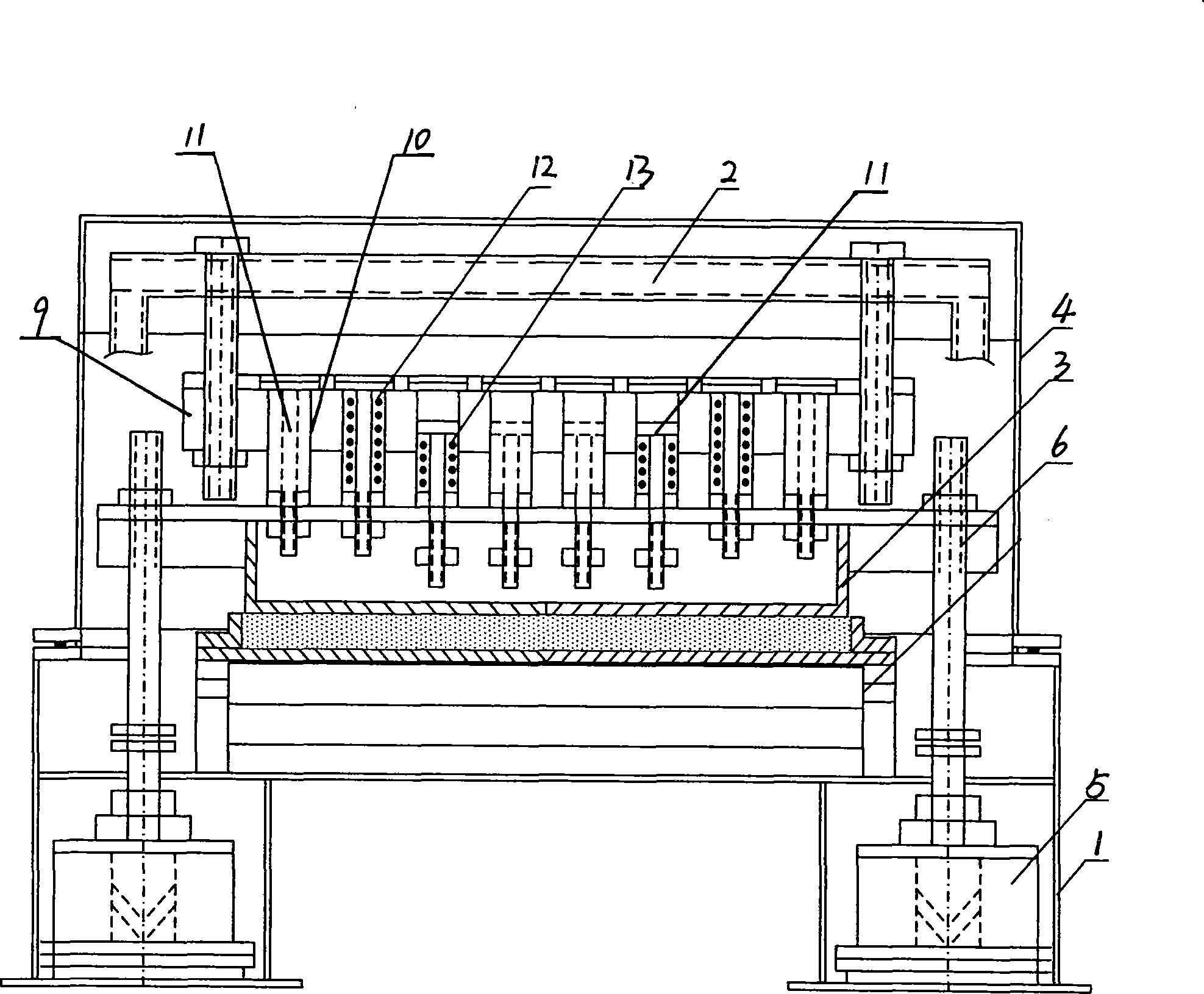

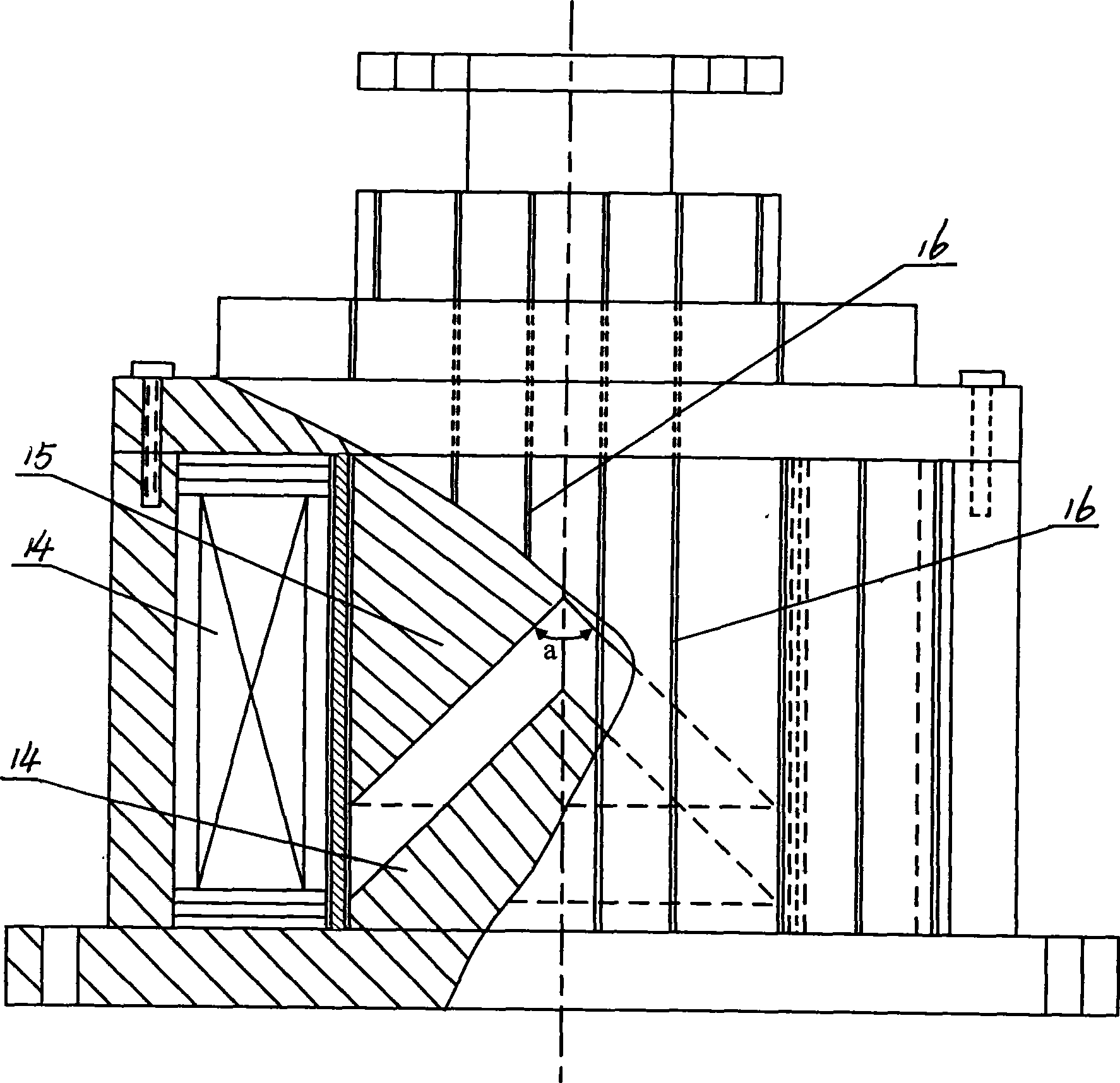

[0018] The electromagnetic artificial quartz stone forming device includes a base 1, an upper frame 2 fixed above the base 1, a vacuum cover 4 with a built-in press tool 3 placed above the base 1, and a vacuum cover 4 fixed on the press tool 3. The electromagnet 5 controls the transmission rod 6 that moves up and down and is perpendicular to the pressure tool 4, and the compression spring that cooperates with the electromagnet 5 to make the transmission rod 6 reciprocate. The end of the transmission rod 6 is fixed to the moving iron core 15 of the electromagnet 5 Connected, the bottom of the moving iron core 15 of the electromagnet 5 is a convex cone or a concave cone, and the static iron core 14 facing the bottom of the moving iron core 15 is a concave cone or a concave cone that forms a parallel gap with the bottom of the moving iron core 15. Convex cone shape, and 45°≤cone angle α≤120°. The outer surface of the moving iron core 15 is evenly distributed with notches 16 paral...

Embodiment 2

[0020] The electromagnetic artificial quartz stone forming device includes a base 1, an upper frame 2 fixed above the base 1, a vacuum cover 4 with a built-in press tool 3 placed above the base 1, and a vacuum cover 4 fixed on the press tool 3. The electromagnet 5 controls the transmission rod 6 that moves up and down and is perpendicular to the presser 3, and the compression spring that cooperates with the electromagnet 5 to make the transmission rod 6 reciprocate. The end of the transmission rod 6 is fixed to the moving iron core 15 of the electromagnet 5 Connected, the bottom of the moving iron core 15 of the electromagnet 5 is a convex cone or a concave cone, and the static iron core 14 facing the bottom of the moving iron core 15 is a concave cone or a concave cone that forms a parallel gap with the bottom of the moving iron core 15. Convex cone shape, and 45°≤cone angle α≤120°. The outer surface of the moving iron core 15 is evenly distributed with notches 16 parallel to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com