Method for manufacturing nano-ferrous acid in supercritical water

A technology of nano-cobalt ferrite and supercritical water, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of complex process and high calcination temperature, and achieve the effect of simple process, good dispersion and easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

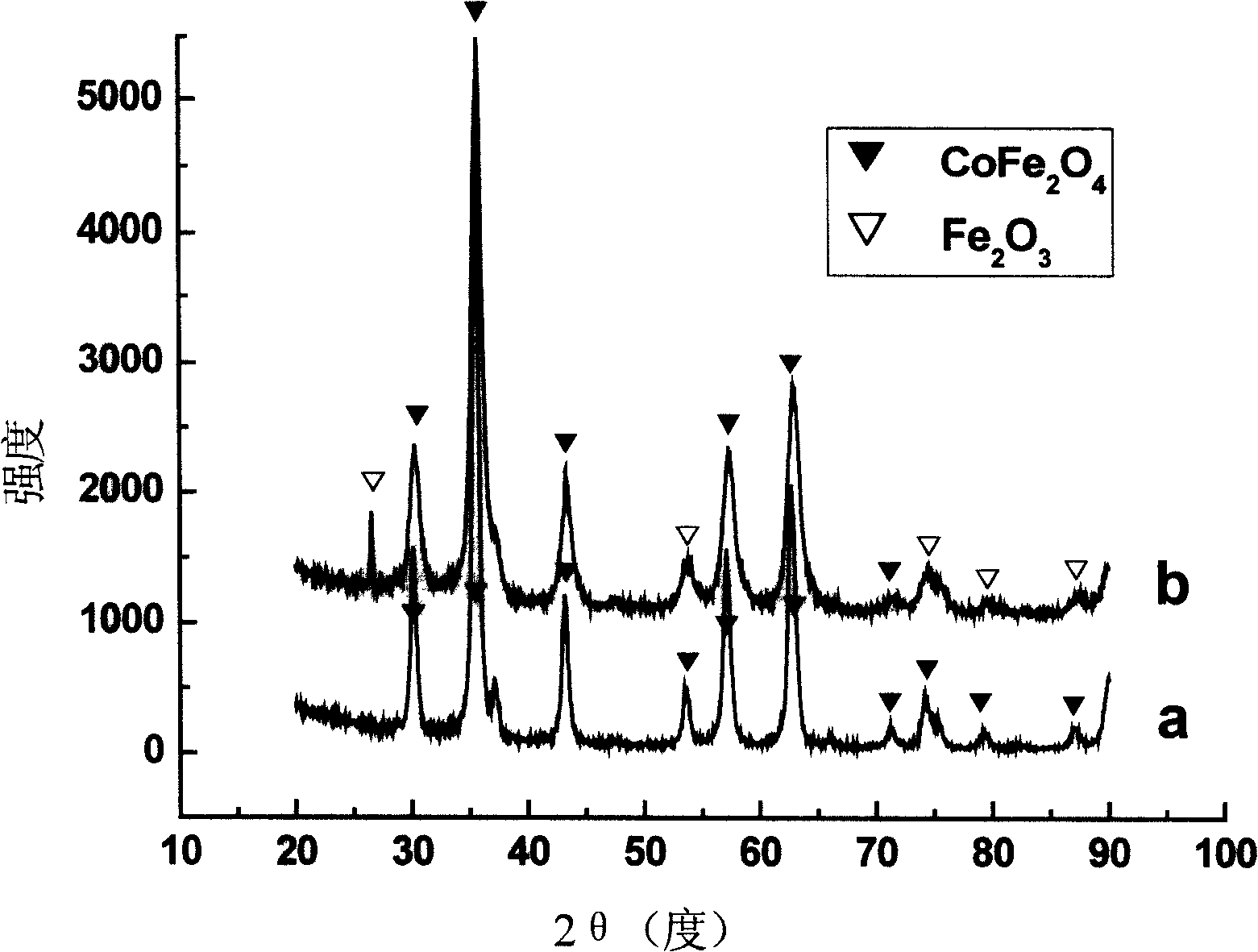

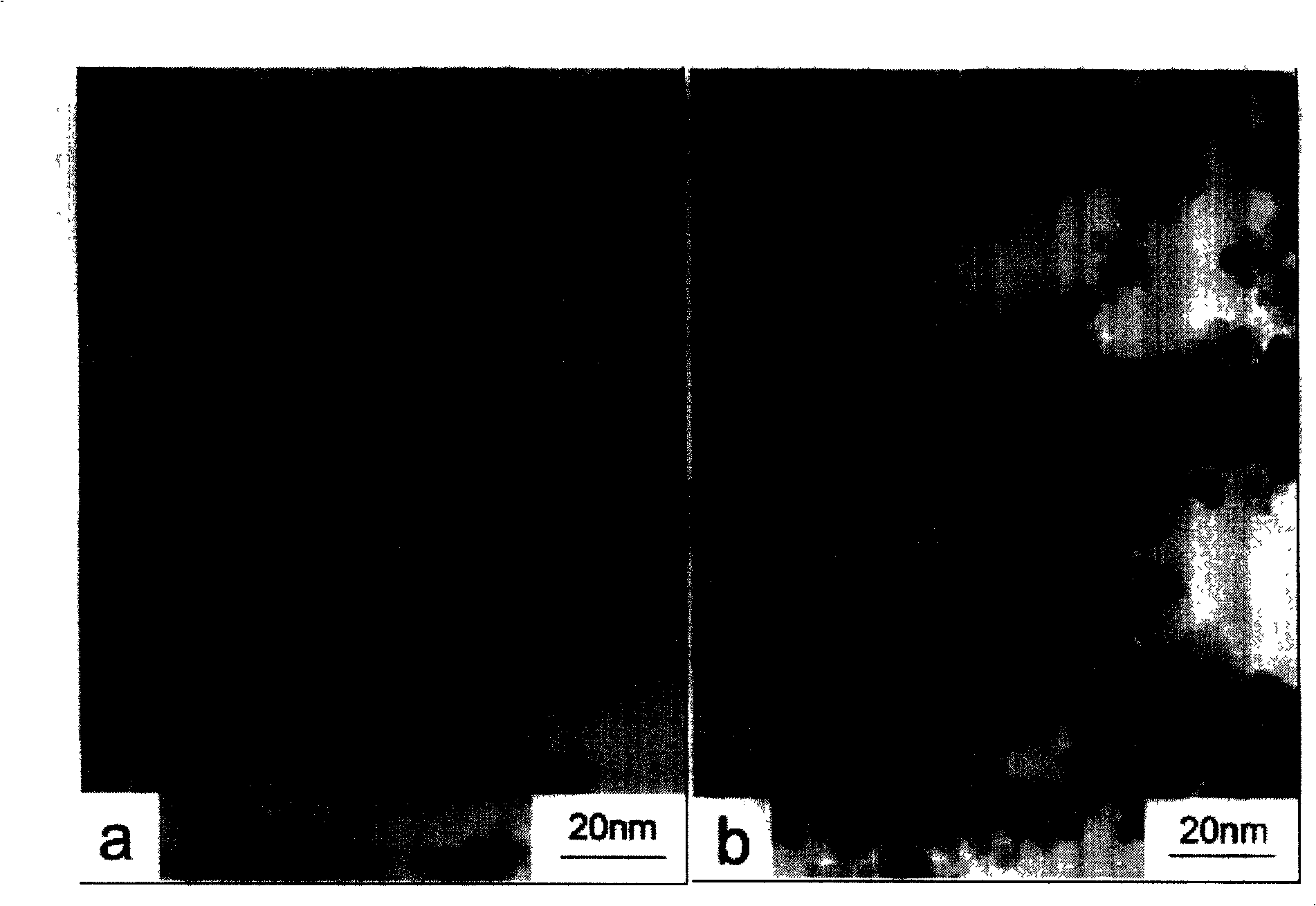

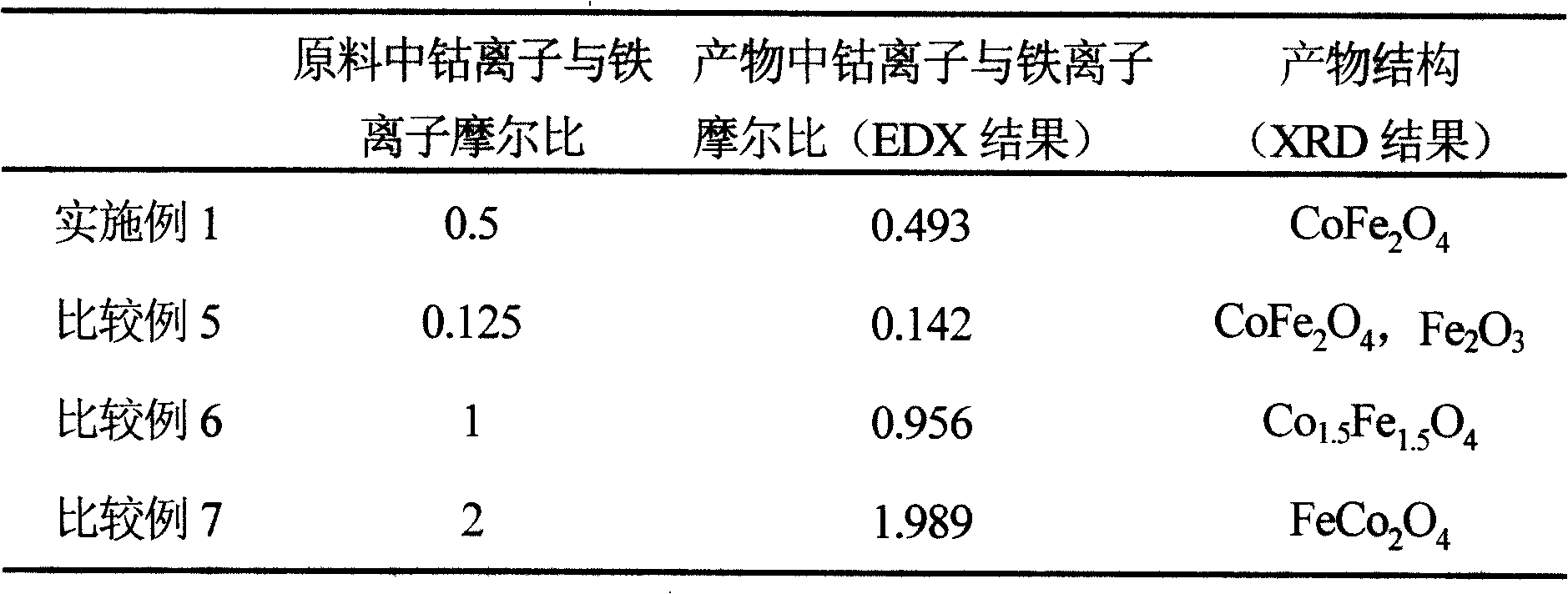

[0032] 2g Co(NO 3 ) 2 ·6H 2 O was dissolved in 150ml deionized water, and Fe(NO 3 ) 3 9H 2 O, make the molar ratio of cobalt ion to iron ion r=0.5, stir the glass rod evenly; add 0.01~0.1mol / L NaOH dropwise to the mixed solution to adjust the pH=11; then pour the mixed solution into the supercritical water reaction equipment, open Heating furnace and magnetic stirrer, heating to 400°C, the corresponding pressure is 3920psi, and reacting for 1h; after the reaction, pass cooling water, pour out the mixture, filter on a vacuum filter, rinse with deionized water until neutral, 25°C Cobalt ferrite particles with good dispersibility can be obtained by drying, the particle size is 3-10nm, see figure 1 a and figure 2 Figure a in.

Embodiment 2

[0034] The difference from Example 1 is that the pH is adjusted to 13; cobalt ferrite particles with good dispersibility and a particle size of 3-10 nm are obtained.

Embodiment 3

[0036] The difference from Example 1 is: 1g Co(NO 3 ) 2 ·6H 2O was dissolved in 150ml deionized water, and Fe(NO 3 ) 3 9H 2 O, make the molar ratio of cobalt ions to iron ions r=0.5, stir evenly with a glass rod; obtain cobalt ferrite particles with good dispersion and particle size of 3-10 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap