Method for manufacturing big diameter borehole filling pile cage of reinforcement

A technology of bored cast-in-place piles and a manufacturing method, which is applied to sheet pile walls, buildings, infrastructure engineering, etc. , The effect of eliminating the deviation in the length direction and eliminating the radial dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

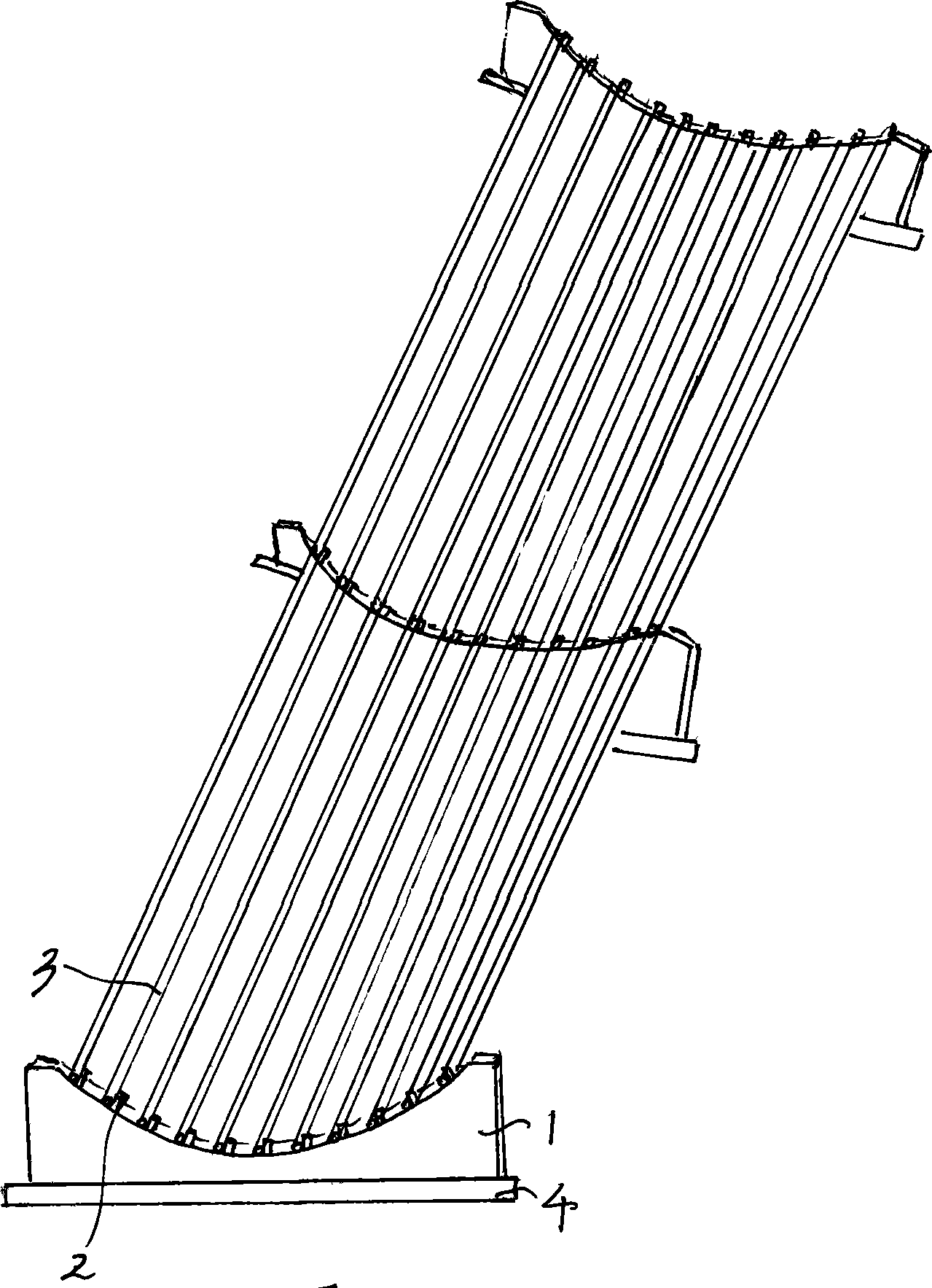

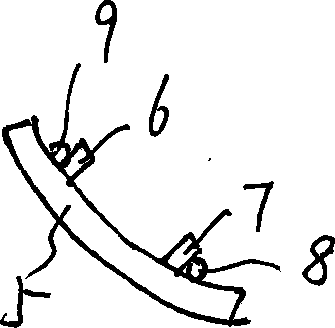

[0012] A method for making a reinforcement cage for bored cast-in-place piles with a large diameter (such as 2500mm or 3000mm in diameter) comprises the following steps: making an arc clamping plate 1 with a 20mm thick steel plate, and the diameter of the arc surface of the clamping plate is outside the main reinforcement of the reinforcement cage. edge diameter, the clamping plate is placed vertically on the inverted channel steel base 4, and the clamping position 2 of the supporting main rib 3 is made on the arc surface of the clamping plate according to the designed interval position of the main rib, and the distance between the clamping position and the clamping position is the design The distance between the main bars; the above-mentioned pallets are arranged every 2 meters along the length direction of the steel cage; On one line, the vertical surface of each pallet is kept perpendicular to the longitudinal centerline of the reinforcement cage, and then the height of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com