Inverse system robust control method for pitch-controlled wind power generation system

A wind power generation system and robust control technology, applied in the control of wind turbines, wind energy power generation, wind turbines, etc., can solve the problems of difficult PID coefficient design, limited control performance, small operating range, etc. The effect of low fatigue level and extended operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039] The inverse system robust control method of the variable pitch wind power generation system proposed by the present invention is described in detail as follows in conjunction with the accompanying drawings and specific implementation methods:

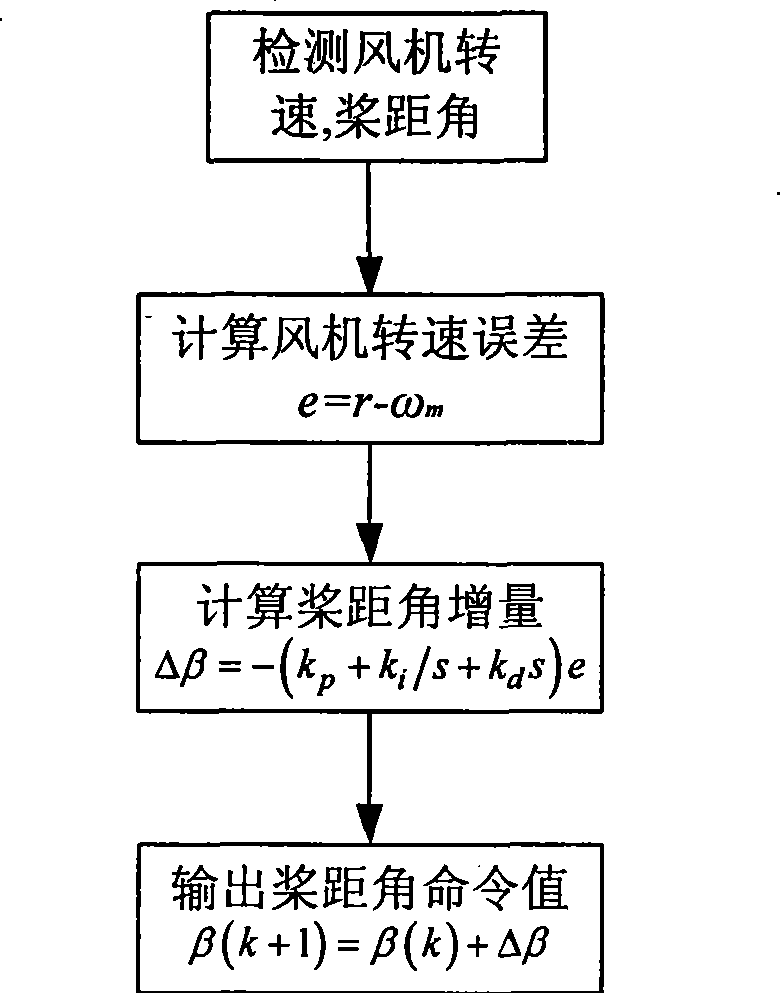

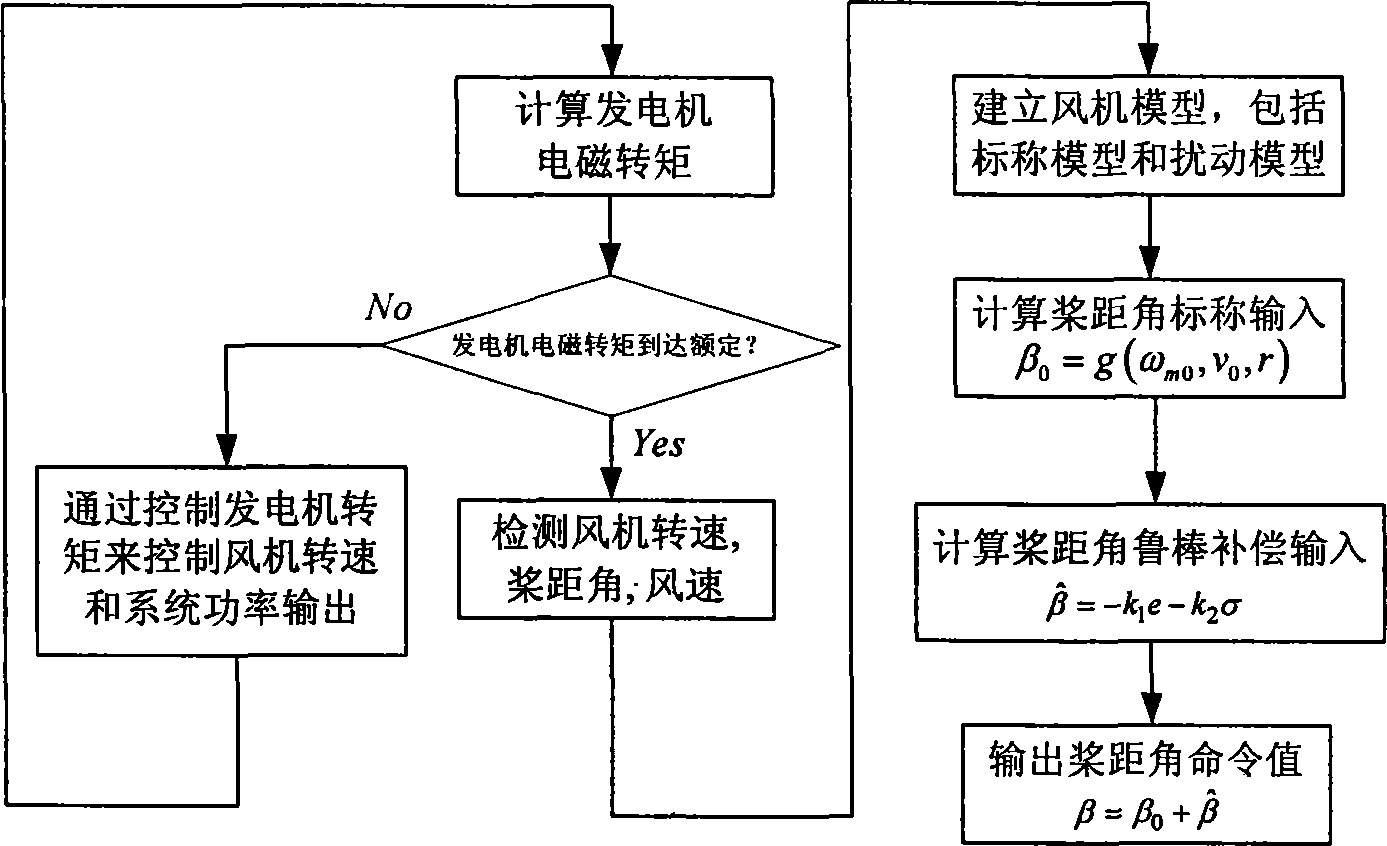

[0040] The method process that the present invention proposes is as figure 2 As shown, the specific steps are as follows:

[0041] 1) Calculate the electromagnetic torque of the generator according to the generator voltage, current and rotational speed; if the electromagnetic torque does not reach the rated value, keep the pitch angle β unchanged, and limit the fan rotational speed and System output power (the control of generator electromagnetic torque can adopt traditional vector control or direct torque control method), if the electromagnetic torque reaches the rated value, the pitch angle adjustment of the fan will be started;

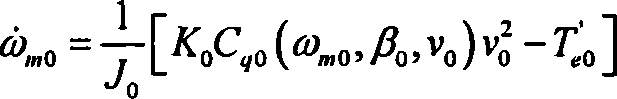

[0042] 2) Establish a model of the wind power generation system, which is the superposition of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com