Contra-rotation gapless driven interlocking tooth synchronous pulley component

A synchronous pulley and gapless technology, which is applied to transmission parts, components with teeth, belts/chains/gears, etc., can solve the problems of affecting the accuracy of reverse transmission and the inability to eliminate tooth side clearances, etc., to improve transmission The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

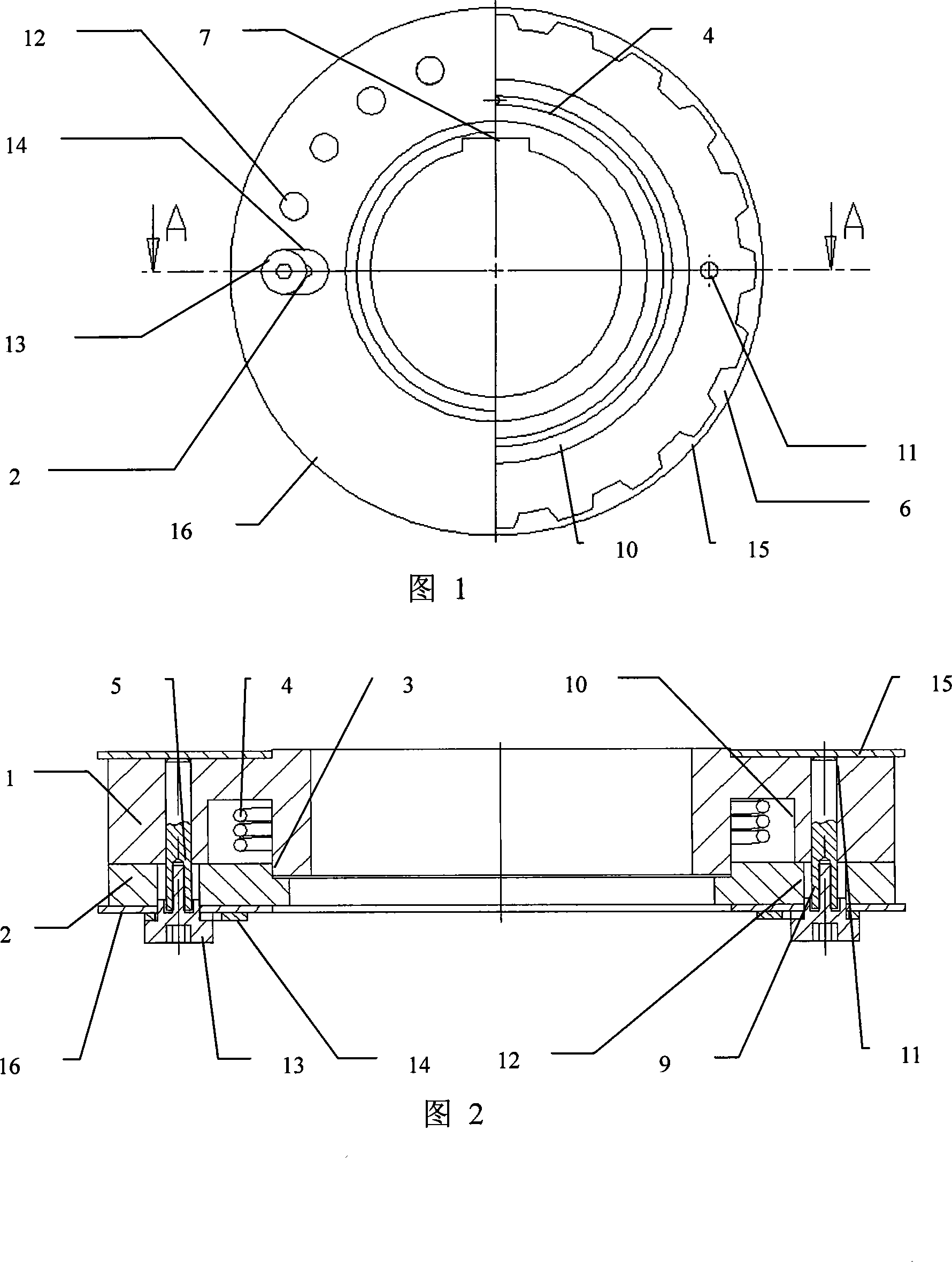

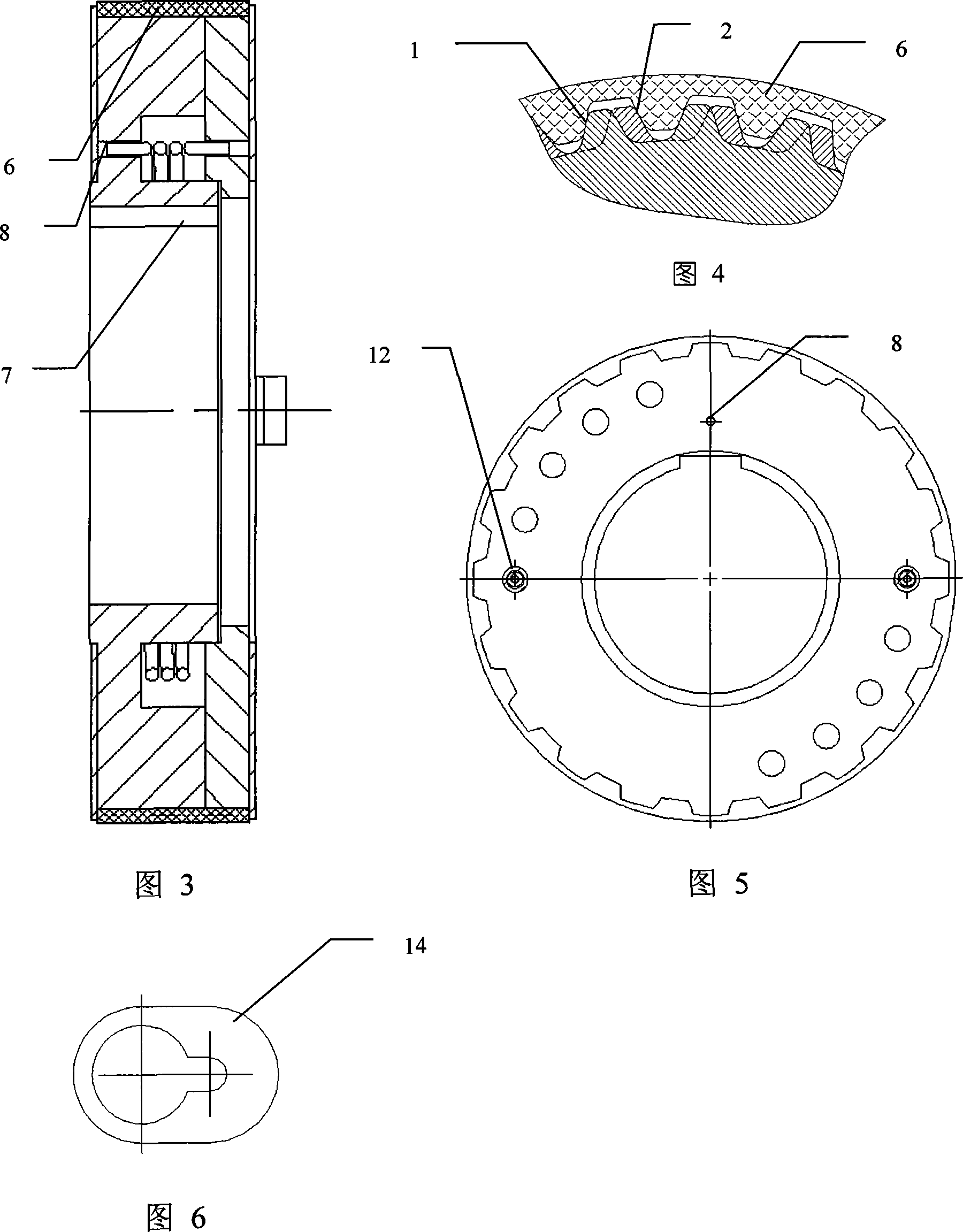

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] As shown in Fig. 1, Fig. 2, Fig. 3, the present invention has keyway 7 on primary pulley 1, and primary and secondary pulley flange shaft hole fit 3 is clearance fit. As shown in Figure 5, the primary pulley 1 and the secondary pulley 2 have pin holes on the same diameter, the two pin holes on the primary pulley 1 are distributed at 180°, and one group of pin holes on the secondary pulley 2 are aligned with the other A group of pin holes with the same number are symmetrically distributed according to the rotation center, wherein the main pulley pin holes 11 are in interference fit with the pin 5, and the main pulley 1 is provided with a ring groove 10, and the ring groove 10 is equipped with a torsion spring 4, and the torsion spring One end of 4 hooks the torsion spring fixing hole 8 of main pulley 1, and the other end of torsion spring 4 hooks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com