Switching valve

A technology for switching valves and valve seats, which is applied in the direction of sliding valves, valve devices, engine components, etc., and can solve problems such as water leakage, short service life, and poor matching precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

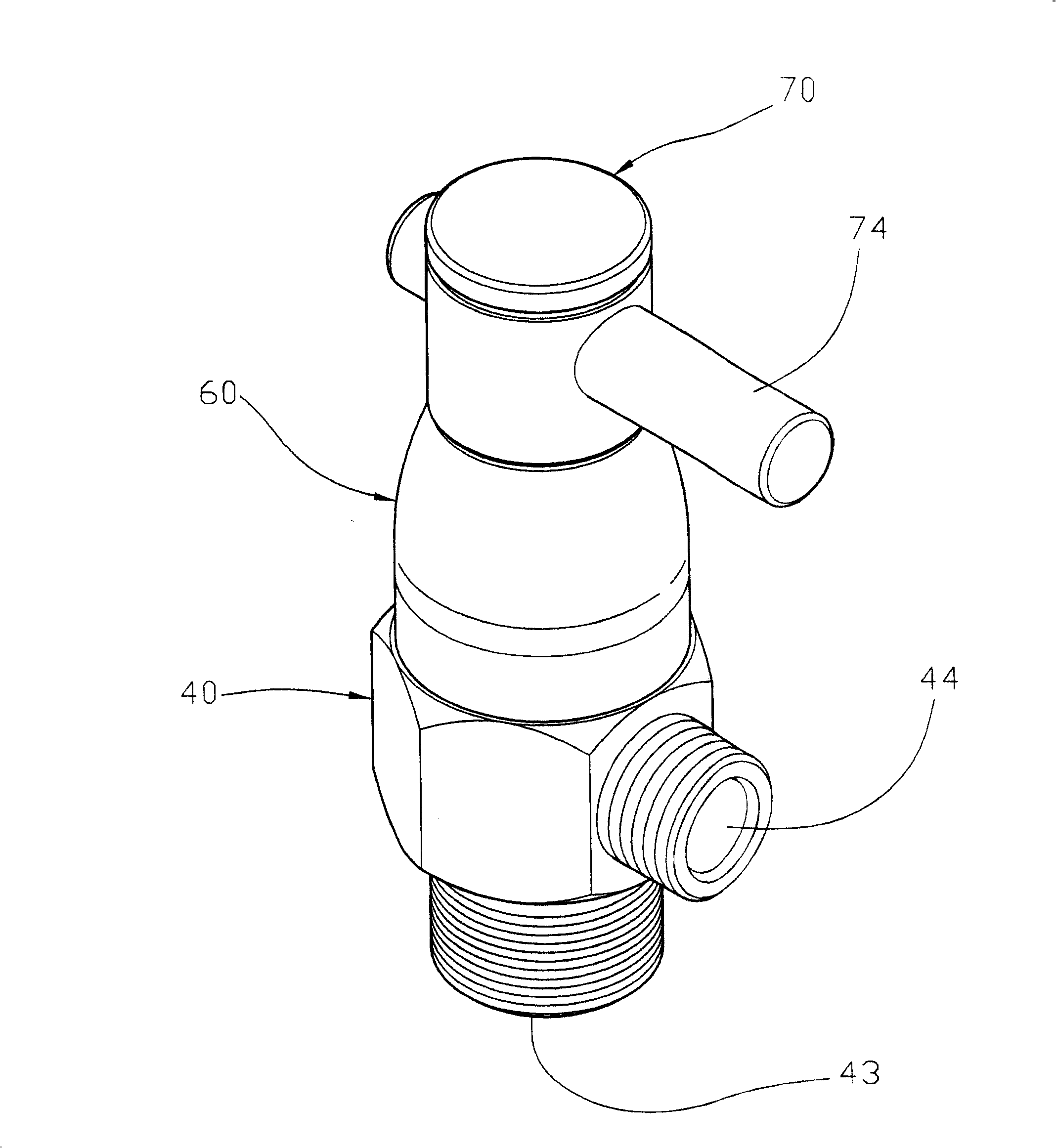

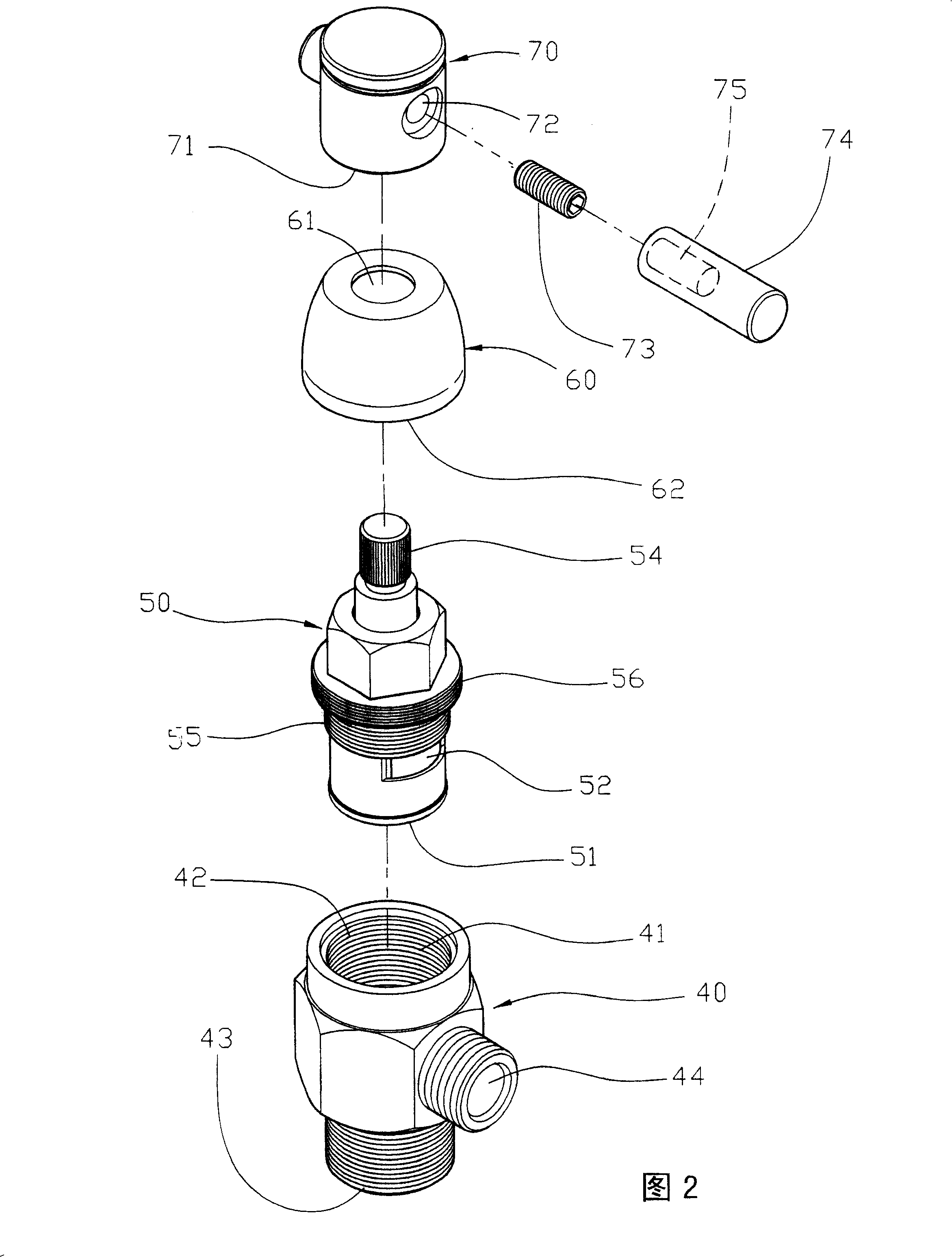

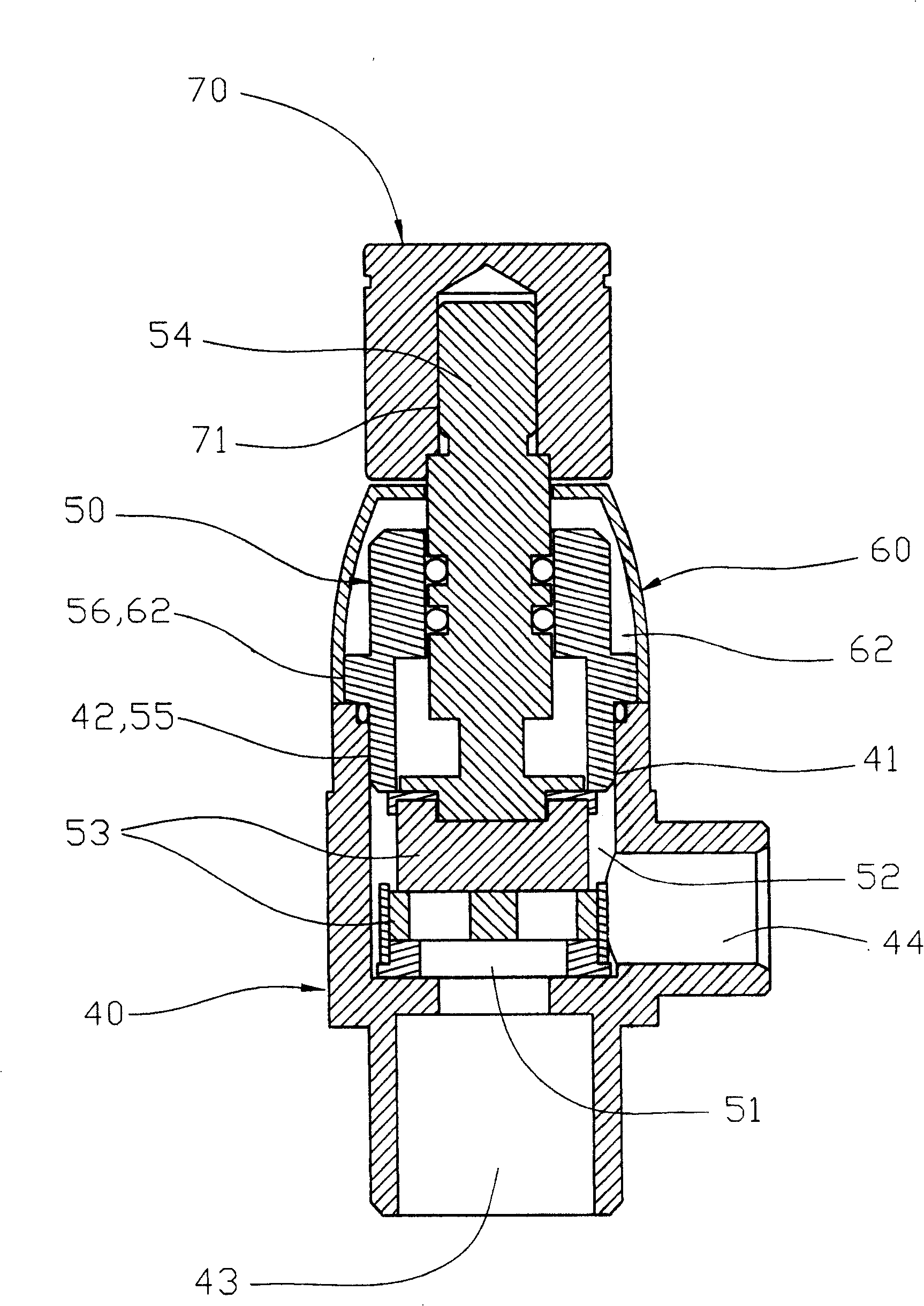

[0026] First of all, please start by figure 1 ,figure 2, image 3 , Figure 4 As shown, it includes: a valve seat 40, a precision ceramic control valve 50, a locking cover 60 and a handle set 70, wherein the valve seat 40 is provided with an accommodating tank chamber 41, the accommodating tank chamber 41 The entire periphery of the body is provided with a threaded locking section 42, and the bottom of the accommodating tank chamber 41 is provided with a water inlet 43, and the outer side is provided with a water outlet 44. The precision ceramic control valve 50 is controlled by a precision ceramic sheet inside. , the bottom is provided with a water inlet 51 and a water outlet 52 is provided on the side. The gap between the water inlet 51 and the water outlet 52 is through a ceramic sheet group 53, and a control rod 54 is extended above the precision ceramic control valve 50. The control The rod 54 is used to control the action of the ceramic disc group 53. In addition, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com