Garbage pool coating and preparation method thereof

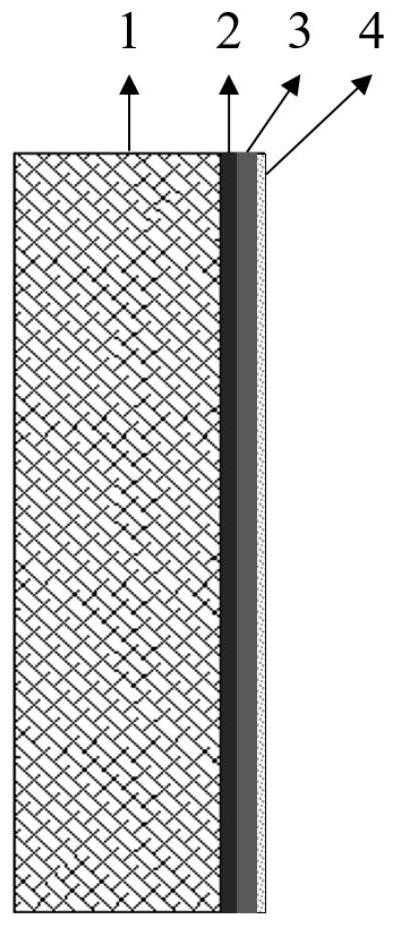

A garbage pond and coating technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problem of difficult to adapt to the service environment and use conditions of corrosive garbage ponds composed of domestic garbage, impermeable garbage ponds and leachate pool layers. Many problems, corrosion resistance, general tolerance, etc., to avoid hidden quality problems, excellent impermeability, and excellent anti-peeling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

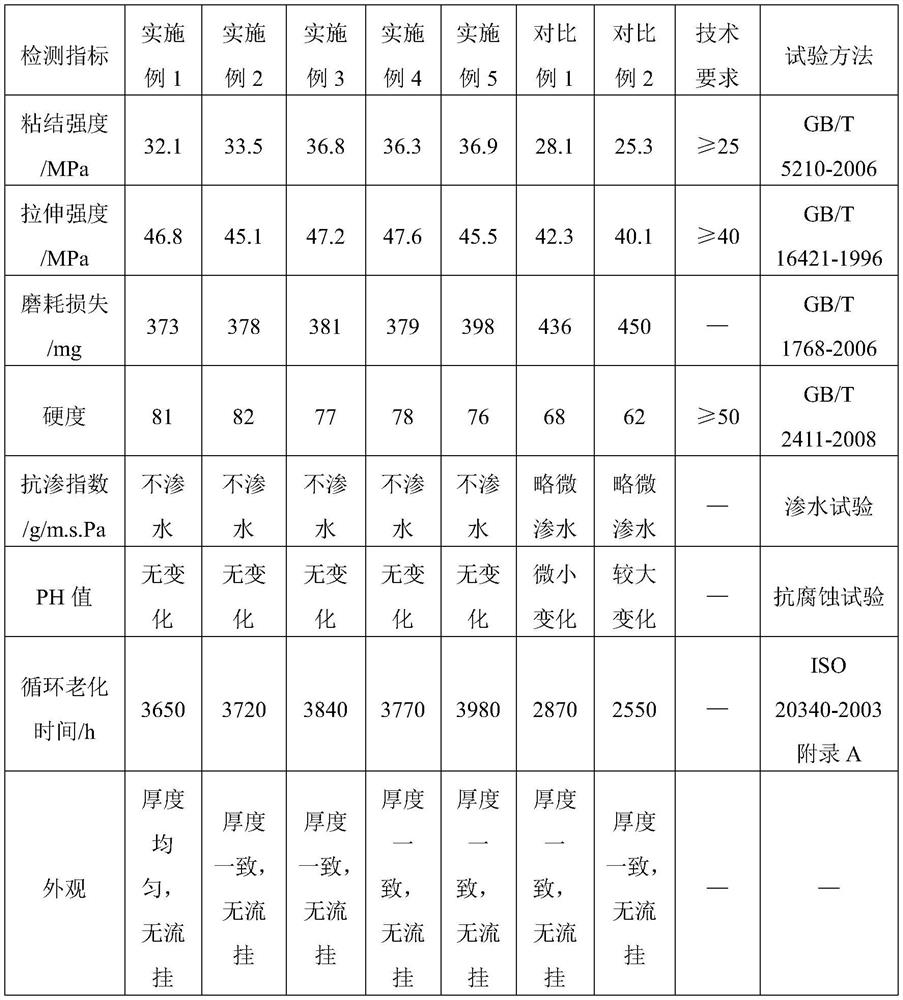

[0031] Example 1: The anti-corrosion coating used in the anti-corrosion layer 2 of the garbage pool coating of the present invention is composed of the following components in parts by mass: 100 parts of diphenol-based propane epoxy resin E51, 25 parts of liquid nitrile rubber, and 1 part of sterilizing agent (The sterilizing agent is blended by zinc oxide, copper phthalocyanine, and tetrahydroxymethyl phosphorus sulfate in a weight ratio of 30:100:10;), 6 parts of resorcinol bisglycidyl ether, 6 parts of BYK-17905 and low Molecular weight curing agent 651 65 parts;

[0032] The impermeable coating used in the impermeable layer 3 is composed of the following components in parts by mass: 100 parts of diphenol-based propane epoxy resin E42, 45 parts of polyurethane prepolymer containing flexible long carbon chains, 2 parts of sterilizing agent (sterilizing agent). It is made of zinc oxide, copper phthalocyanine, phosphorus tetrahydroxymethyl sulfate (45:100:15 by weight), 4 part...

Embodiment 2

[0040] Example 2: The anti-corrosion coating used in the anti-corrosion layer 2 of the garbage pool coating of the present invention is composed of the following components in parts by mass: 60 parts of diphenol-based propane epoxy resin E51, 20 parts of liquid nitrile rubber, and 2 parts of sterilizing agent (The sterilizing agent is blended by zinc oxide, copper phthalocyanine, and tetrahydroxymethyl phosphorus sulfate in a weight ratio of 30:100:10;), 4 parts of resorcinol bisglycidyl ether, 4 parts of BYK-17904 and low Molecular weight curing agent 651 60 parts;

[0041] The impermeable coating used in the impermeable layer 3 is composed of the following components in parts by mass: 60 parts of diphenol-based propane epoxy resin E42, 40 parts of polyurethane prepolymer containing flexible long carbon chains, and 3 parts of sterilizing agent (sterilizing agent). It is made of zinc oxide, copper phthalocyanine, tetrahydroxymethyl phosphorus sulfate (45:100:15 by weight), 3 p...

Embodiment 3

[0049] Example 3: The anti-corrosion coating used in the anti-corrosion layer 2 of the garbage pool coating of the present invention is composed of the following components in parts by mass: 80 parts of diphenol-based propane epoxy resin E51, 30 parts of liquid nitrile rubber, and 2 parts of sterilizer (The sterilizing agent is blended by zinc oxide, copper phthalocyanine, and tetrahydroxymethyl phosphorus sulfate in a weight ratio of 30:100:10;), 8 parts of resorcinol bisglycidyl ether, 8 parts of BYK-17907 and low Molecular weight curing agent 651 70 parts;

[0050] The impermeable coating used in the impermeable layer 3 is composed of the following components in parts by mass: 80 parts of diphenol-based propane epoxy resin E42, 50 parts of polyurethane prepolymer containing flexible long carbon chains, and 3 parts of sterilizing agent (sterilizing agent). It is made of zinc oxide, copper phthalocyanine, phosphorus tetrahydroxymethyl sulfate (45:100:15 by weight), resorcinol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com