Three-axis stepping motor control platform

A stepper motor and control platform technology, applied in the direction of electrical program control, digital control, circuit, etc., can solve the problems of large restrictions and high cost, and achieve the effect of complete functions, high positioning accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

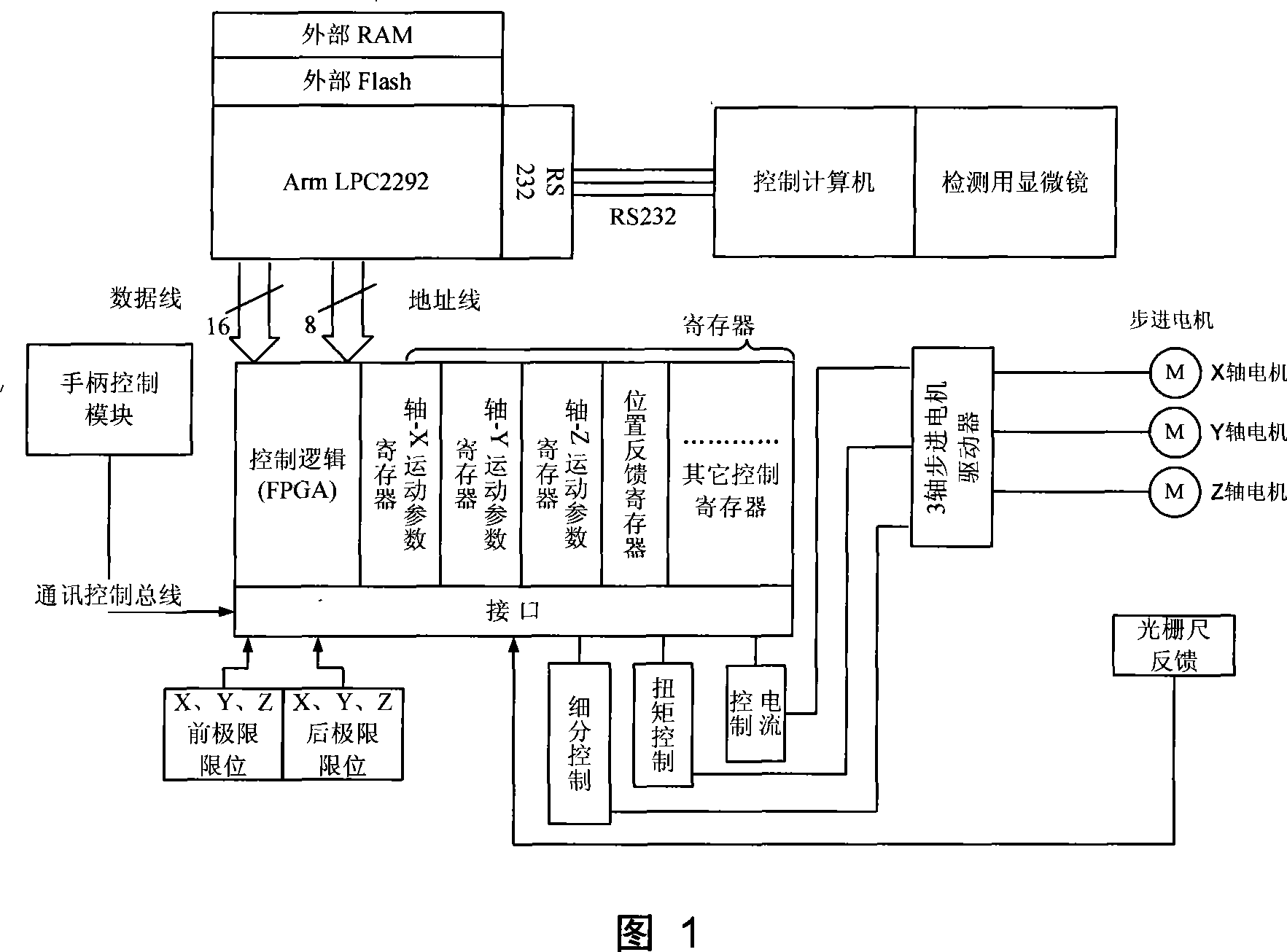

[0024] Figure 1 shows the structural principle block diagram of the system, from which it can be seen that the entire control platform is divided into 5 parts:

[0025] ARM processor part: This part also includes external RAM and external Flash. The external RAM stores temporary data during operation, and the external Flash is used to store the running code of ARM. The ARM communicates with the host through the RS232 interface and receives control commands from the control computer. ARM communicates with the microscope for wafer inspection through another RS232 interface, sends control commands to the microscope, and controls the conversion of the diaphragm and eyepiece of the microscope. ARM is connected to FPGA through 16 data lines and 8 address lines, and exchanges data with FPGA.

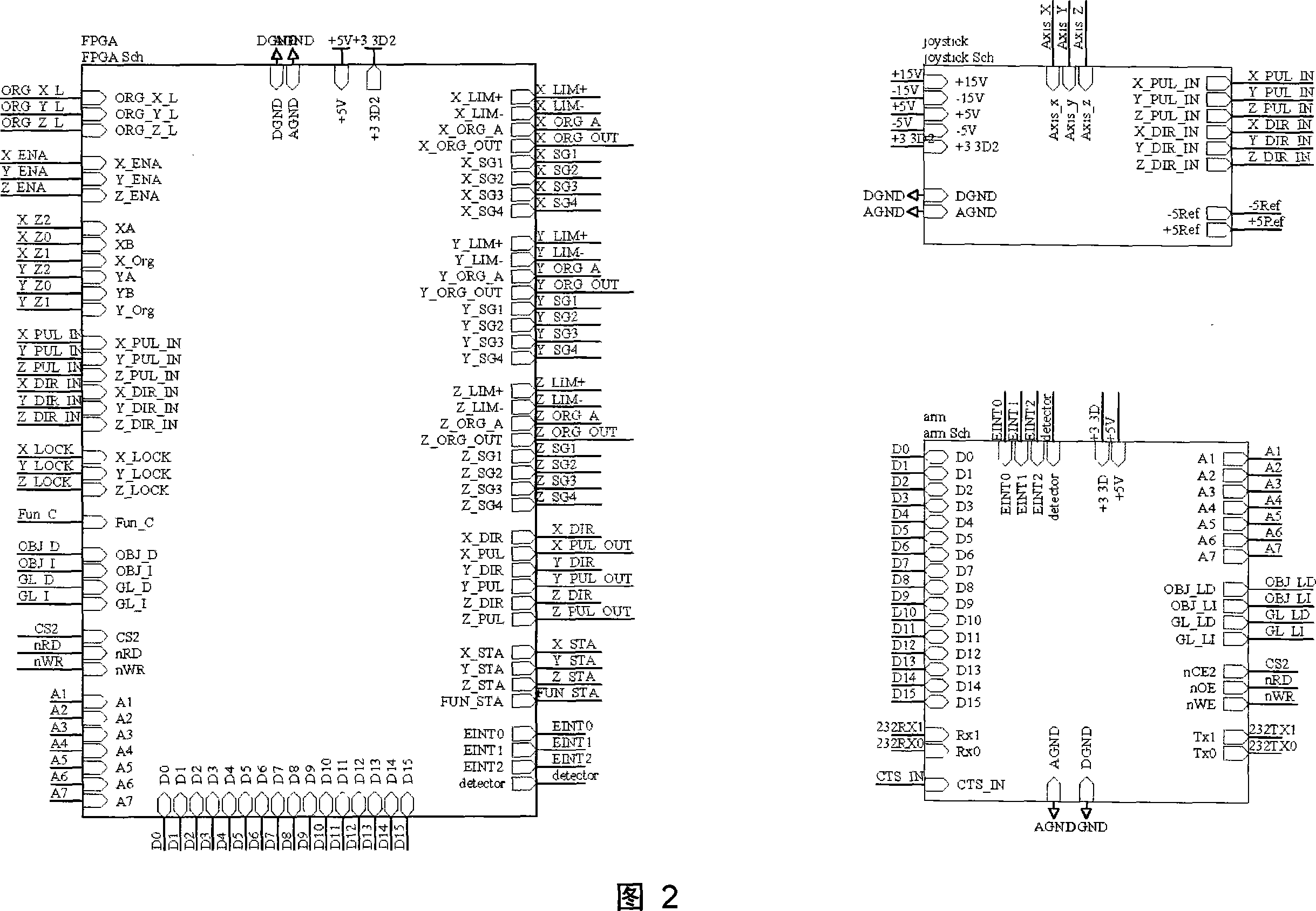

[0026] FPGA part: There are several motion control registers inside the FPGA. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com