Low-fluctuation rare earth permanent magnetic brushless motor

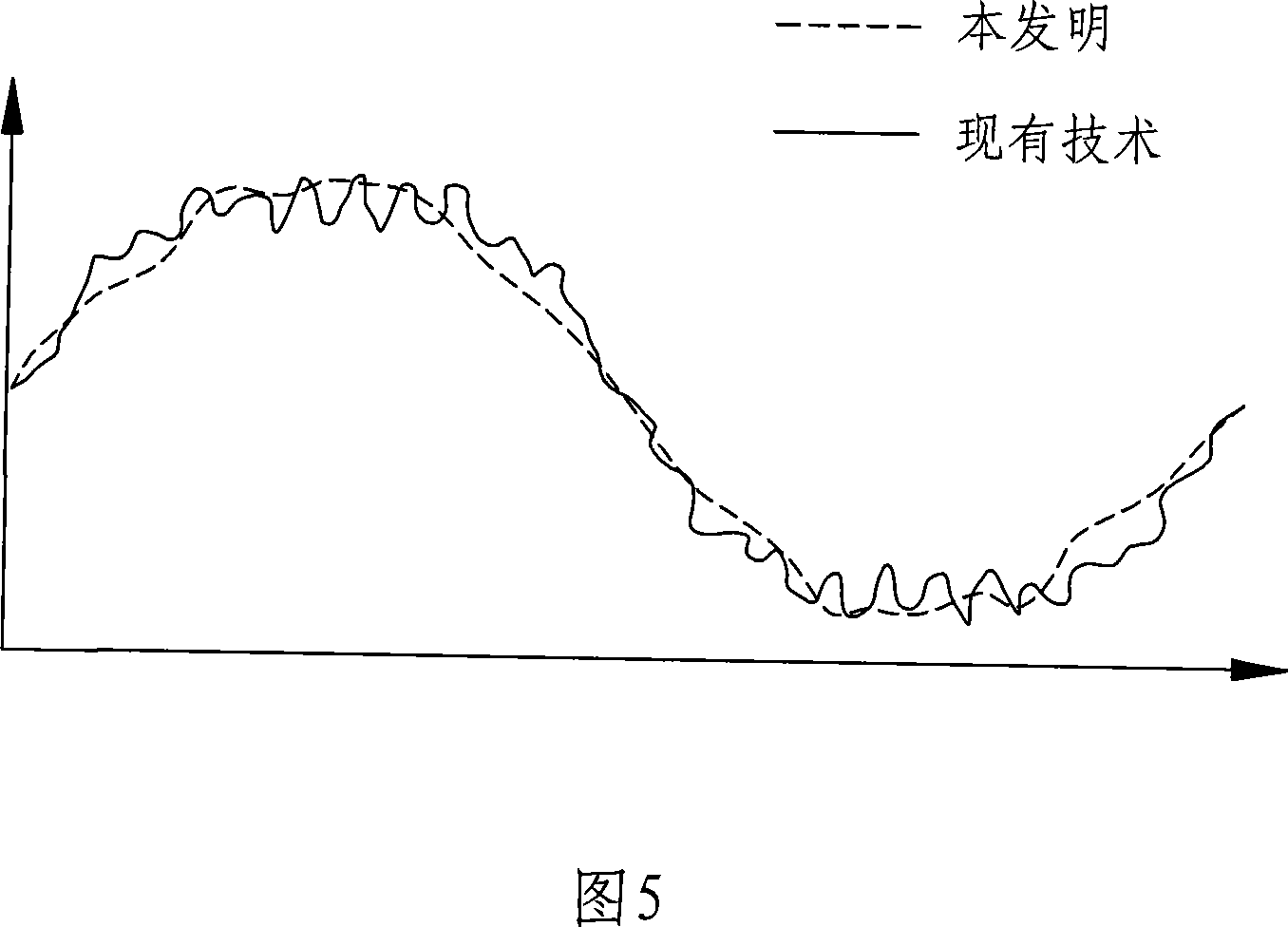

A technology of brushless motors and rare earth permanent magnets, which is applied to the static parts of the magnetic circuit, the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems of difficult processing and complex structure, and improve the voltage Waveform, reduction of torque ripple, effects of silent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

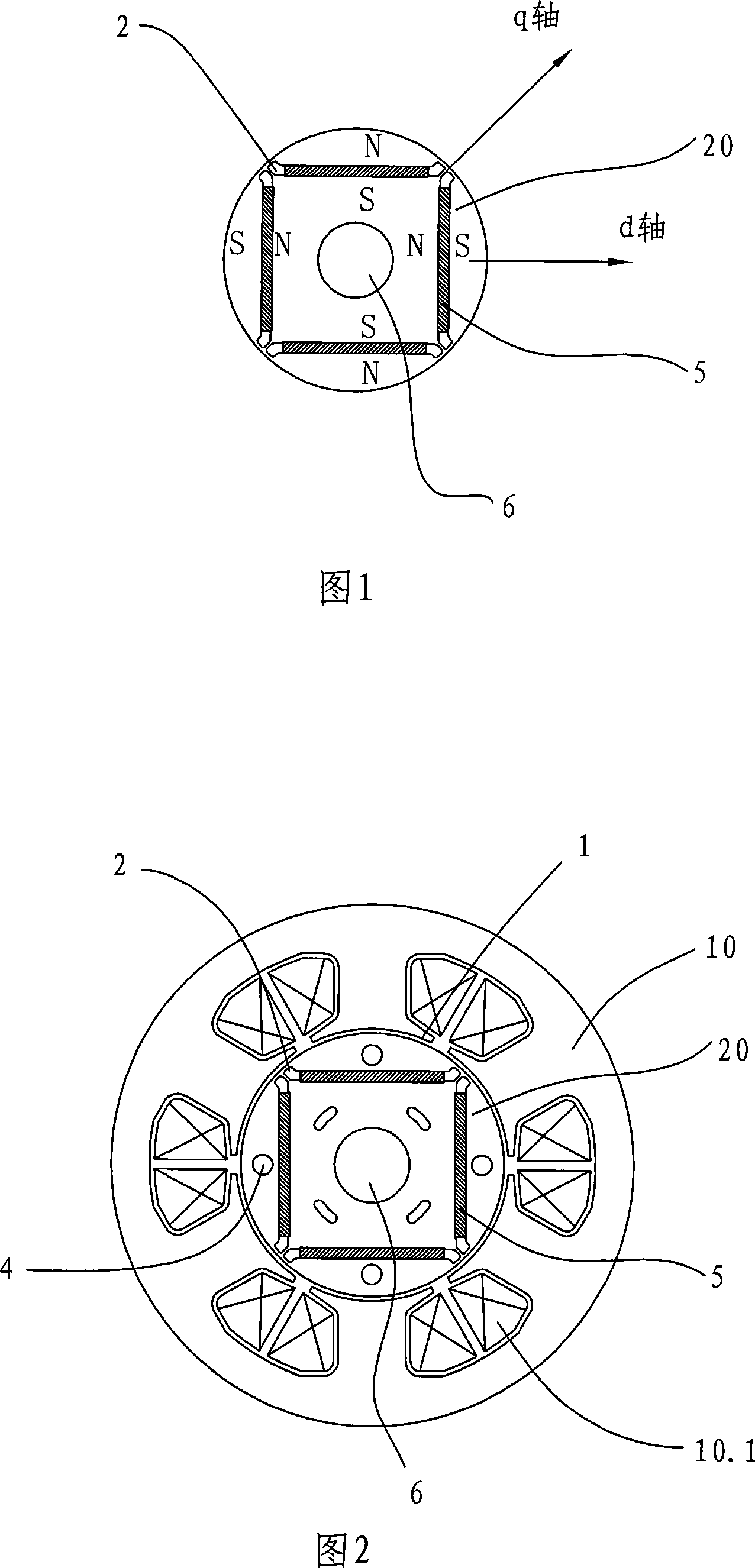

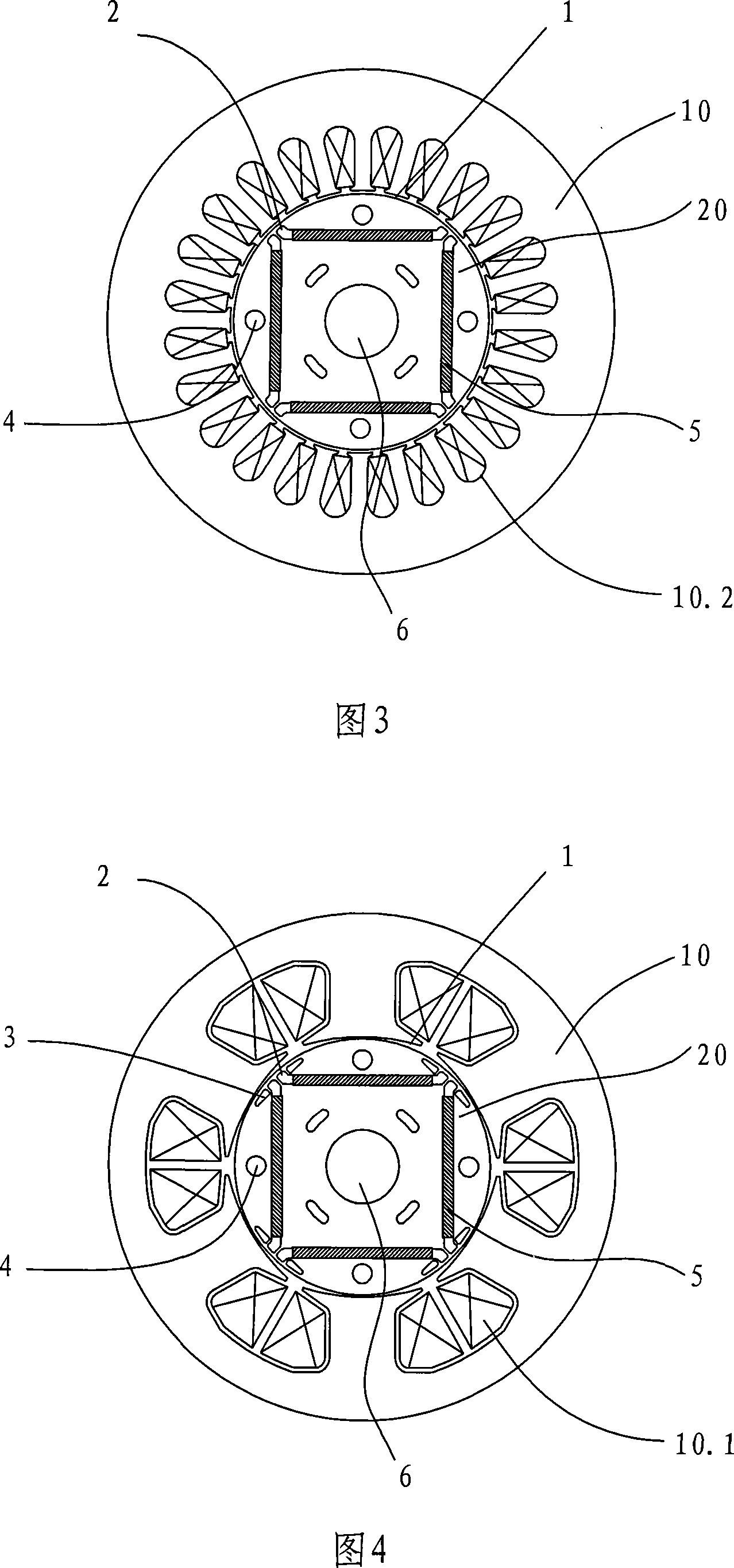

[0017] Referring to Fig. 4-Fig. 5, the low-pulsation rare-earth permanent magnet brushless motor includes a stator 10 and a rotor 20. The rotor is formed into a column by stacking punched sheets. There is a radial air gap 1 between the stator and the rotor. The stator yoke There is a minimum air gap between the outer diameter of the stator and the outer diameter of the rotor, generally 0.1 to 2 mm, and the largest air gap between the slot of the stator and the outer diameter of the rotor, and the largest air gap is 1.5 to 6.0 times the smallest air gap. The six circular arcs on the inner diameter of the stator are located at different centers respectively, and the circular arcs of each segment are evenly distributed along the inner diameter of the stator, wherein the radius of each circular arc is greater than the radius of the rotor punch.

[0018] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com