Method for combining film switch and plastic base by intra-mode injection molding and its finished product

A membrane switch, in-mold injection technology, applied to electrical switches, circuit layouts on support structures, electrical components, etc., can solve problems such as easy separation or falling off, damage to membrane switches or electronic components, and multiple processing procedures. The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

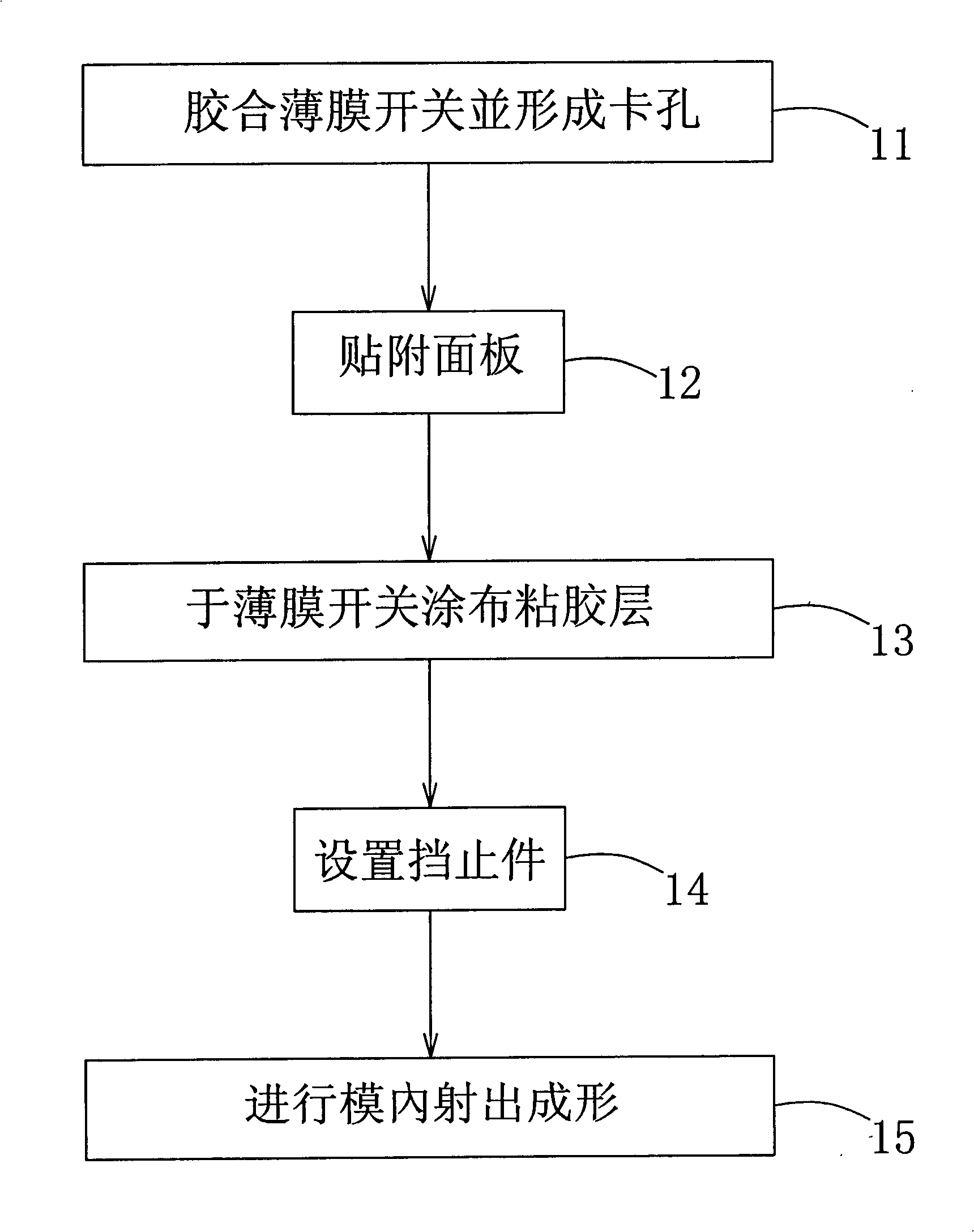

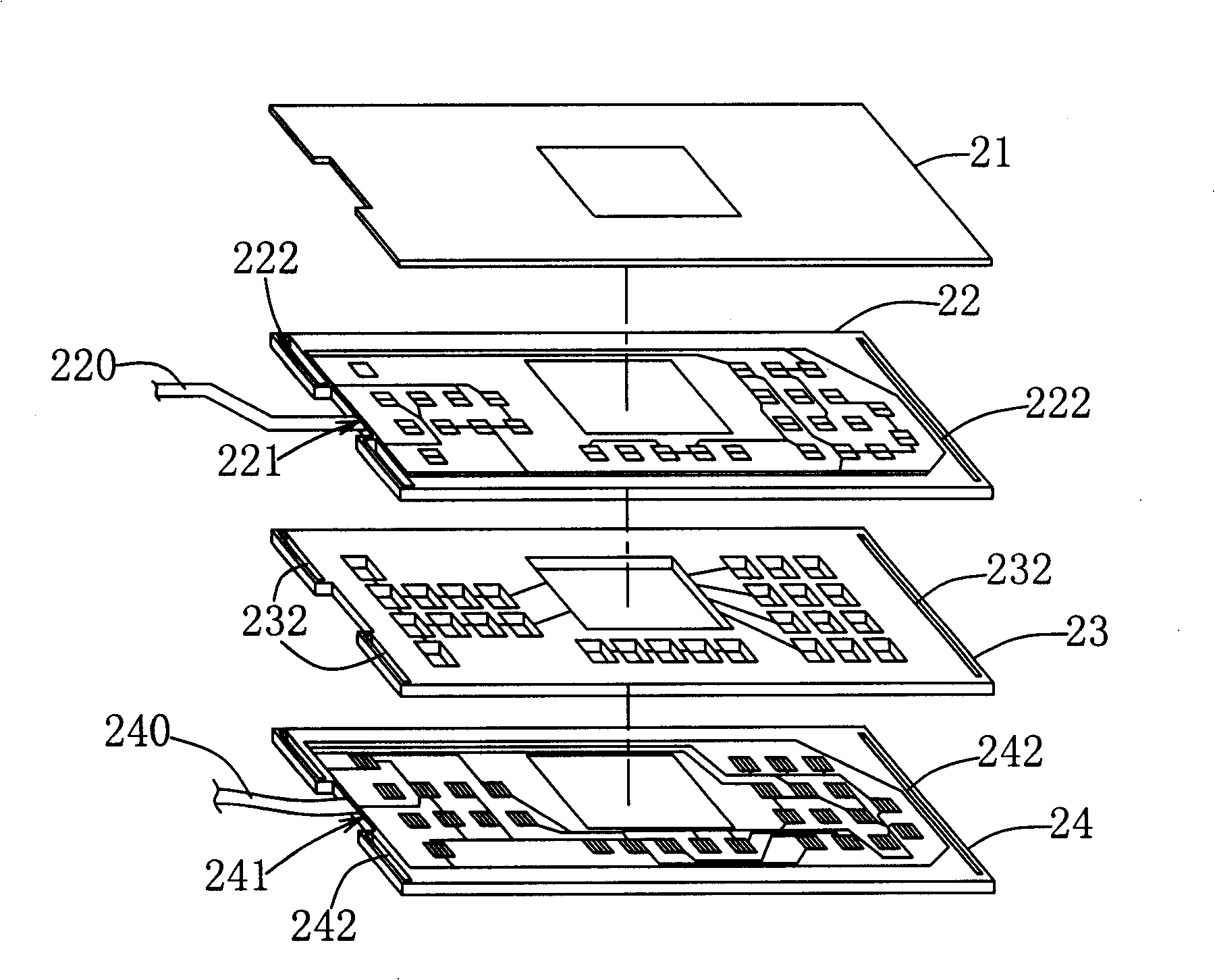

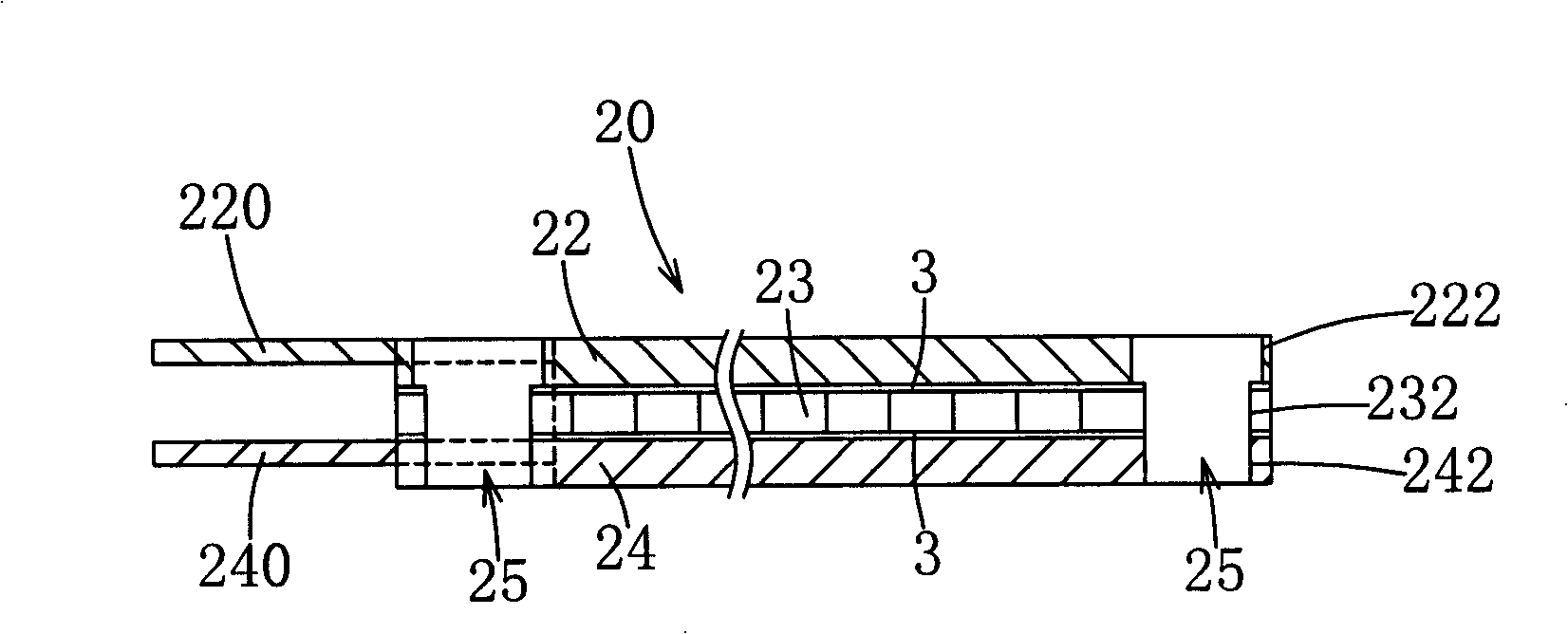

[0031] refer to figure 1 and figure 2 , in the method of combining the membrane switch and the plastic base by injection molding in the present invention, the combined membrane switch 2 includes a membrane panel 21 , an upper circuit layer 22 , a middle through-hole layer 23 and a lower circuit layer 24 . Wherein, the film panel 21 is a transparent film made of polyethylene terephthalate (hereinafter referred to as PET), but the material of the film panel 21 can also be acrylic (PMMA), polyvinyl chloride (polyvinyl chloride) , PVC), polycarbonate (polycarbonate, PC) and polyethylene (polyethlene, PE) materials, etc., the film panel 21 can be printed on the key text, patterns, patterns or colors that can transmit light. The upper and lower circuit layers 22, 24 are composed of circuits printed with conductive silver paste (or conductive silver and carbon paste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com