Valve timing regulation device

A technology for adjusting devices and valve timing, which is applied to valve devices, engine components, machines/engines, etc. It can solve problems such as poor assembly, falling off, and high processing accuracy, and achieve excellent manufacturability, easy manufacturing, and improved processing and assembly. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, in order to explain the present invention in more detail, the best mode for carrying out the present invention will be described with reference to the drawings.

[0028] Implementation form 1.

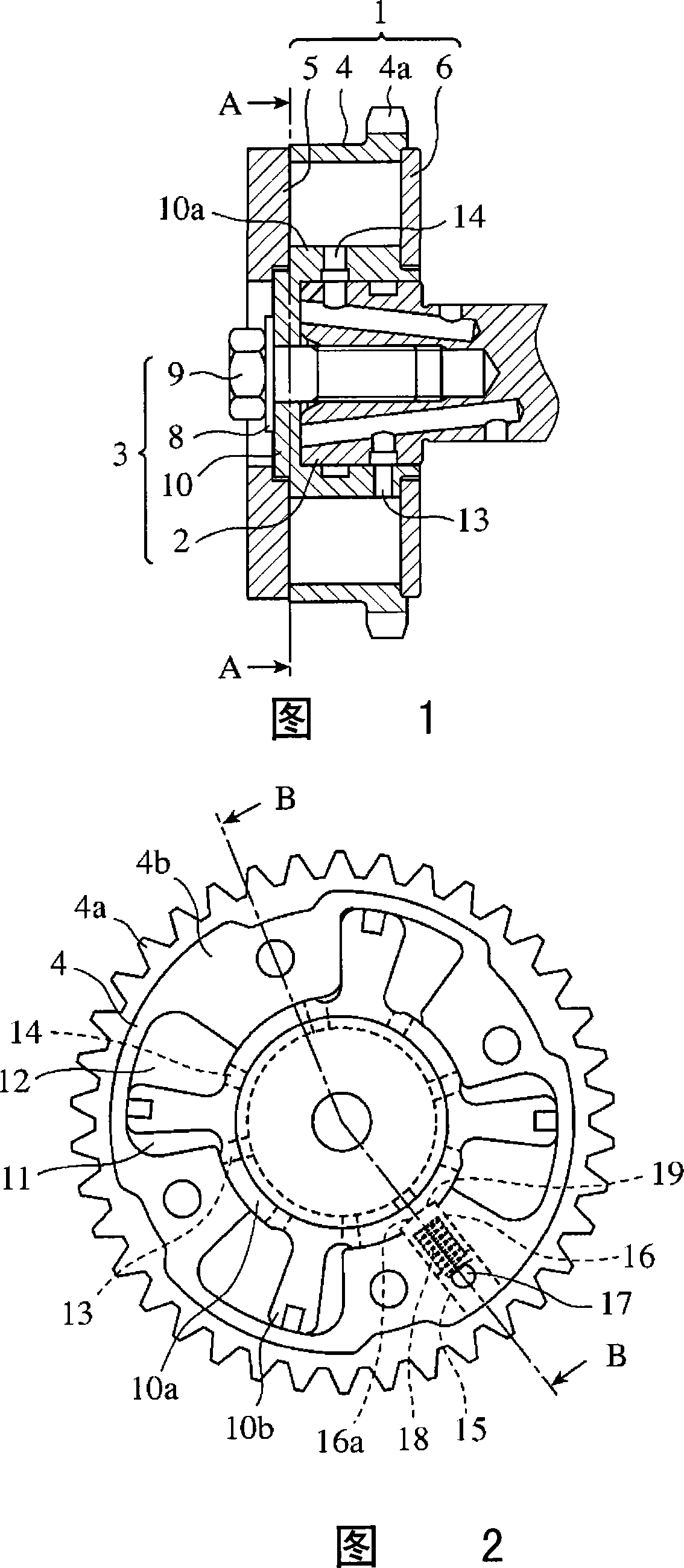

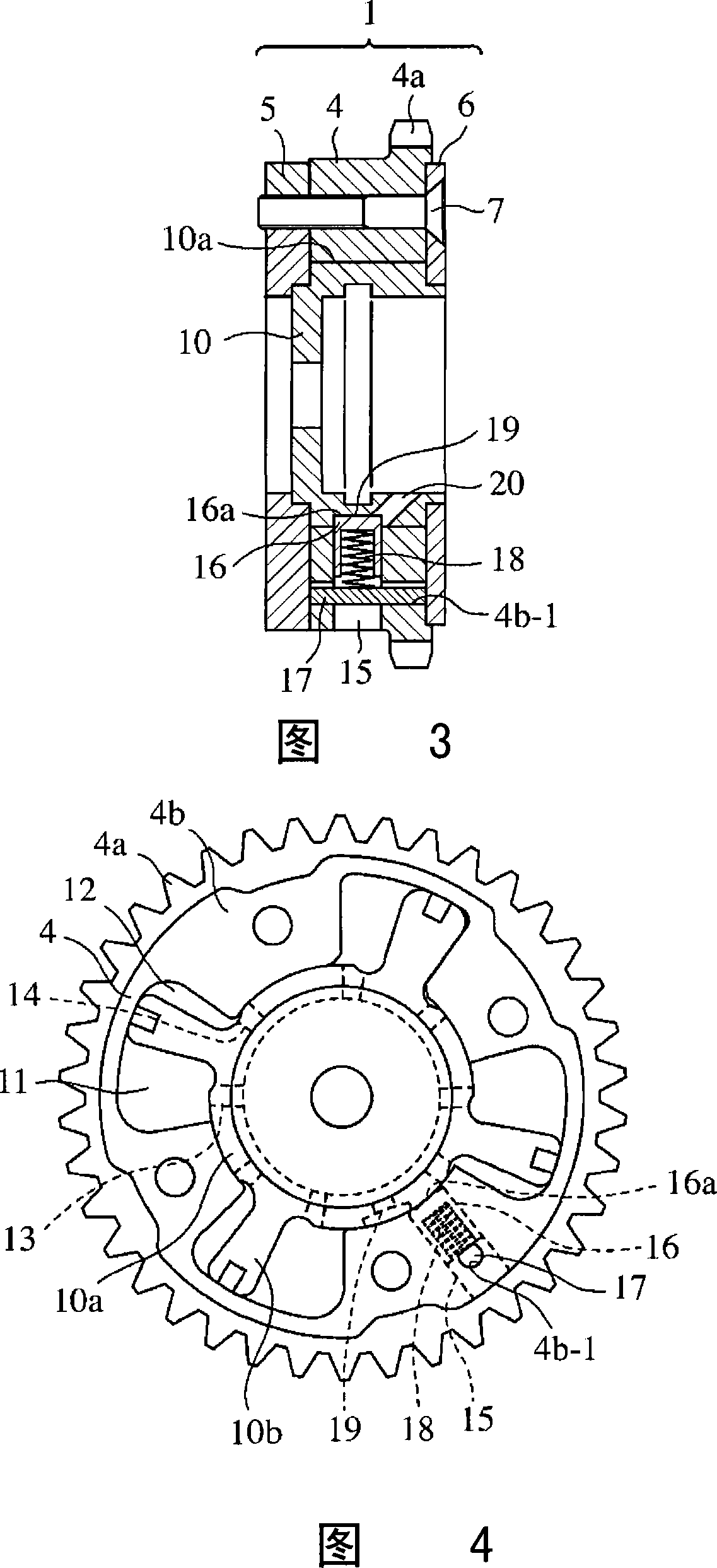

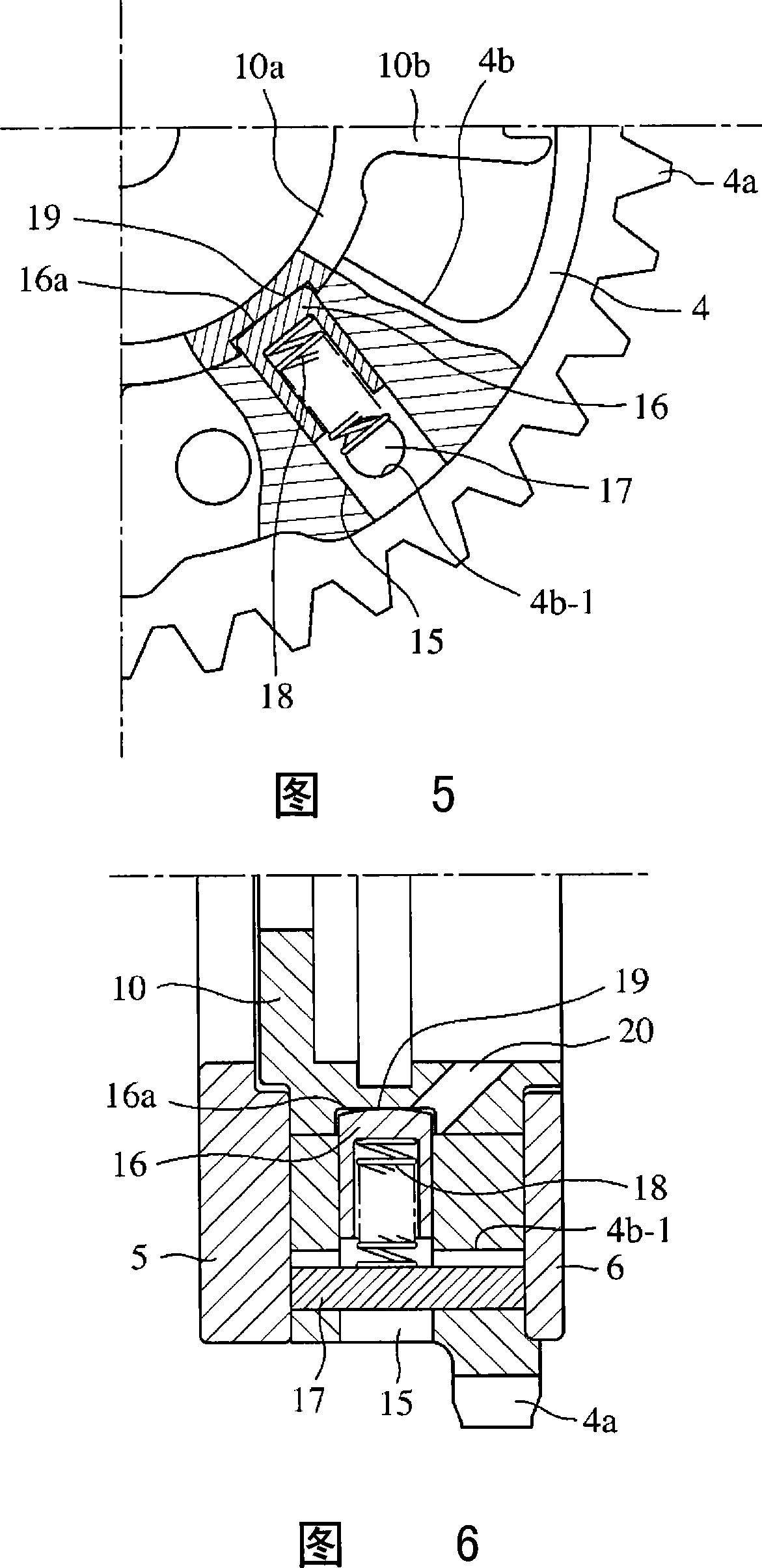

[0029] The accompanying drawings show the internal structure of the valve timing adjustment device according to Embodiment 1 of the present invention. FIG. 1 is a longitudinal sectional view of the valve timing adjustment device when the second rotating body is located at the maximum retardation angle position. FIG. A cross-sectional view along line A-A, Fig. 3 is a longitudinal sectional view along line B-B in Fig. 2, and Fig. 4 is a longitudinal sectional view of the valve timing adjustment device when the second rotating body is at the most advanced angle position.

[0030] As shown in FIGS. 1 to 4 , the valve timing adjustment device 1 according to Embodiment 1 roughly includes: a first valve that rotates synchronously with a crankshaft (not shown) of an engine (not sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com