Sterilization bolt

A technology of guide rods and films, applied in the field of sterilization plugs, can solve the problems of high cost and high requirements, and achieve the effects of low cost, high success rate of sterilization, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

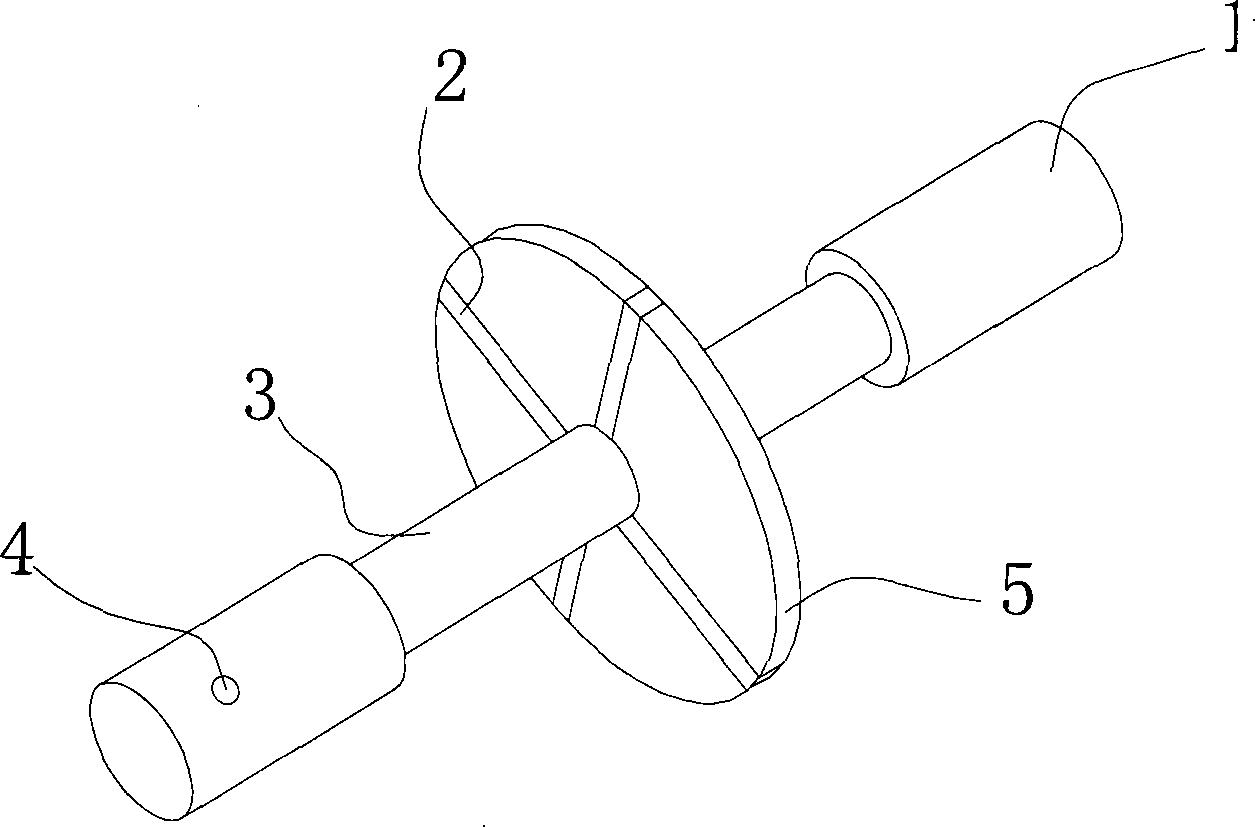

[0012] Example one: such as figure 1 As shown, the sterilization plug of the present invention is made of TiNi alloy, wherein the weight percentage of Ni is 56%, and the balance is Ti. The sterilization plug includes a guide rod 1 and four radial brackets 2 connected around the guide rod 1, and a film 5 is adhered to the bracket 2. The cross section of the guide rod 1 and the film 5 adhered to the support 2 is round. The guide rod 1 has a length of 4 mm and a diameter of 0.2 mm, and each radial stent 2 has a length of 1 mm and a thickness of 0.1 mm. On the surface of the guide rod 1 at least one side close to the bracket 2 is provided with a groove 3 surrounding the guide rod 1. The length of the groove 3 is 1 mm, and the diameter of the guide rod 1 where the part of the groove 3 is located is 0.1 mm. The film 5 is adhered to the stent 2 and its size is adapted to the radial stent 2. The stent 2 can be folded into the groove at a softening temperature of 10°C. After the sterilizat...

Embodiment 2

[0013] Embodiment 2: The sterilization plug of the present invention is made of TiNi alloy, wherein the weight percentage of Ni is 56.5%, and the balance is Ti. The sterilization plug includes a guide rod 1 and six radial stents 2 connected around the guide rod 1, and a film 5 is adhered to the stent 2. The cross section of the guide rod 1 and the film 5 adhered to the support 2 is round. The guide rod 1 has a length of 6 mm and a diameter of 0.5 mm, and each radial stent 2 has a length of 2 mm and a thickness of 0.3 mm. On the surface of the guide rod 1 at least one side close to the bracket 2 is provided with a groove 3 surrounding the guide rod 1. The length of the groove 3 is 2 mm, and the diameter of the guide rod 1 where the part of the groove 3 is located is 0.2 mm. The film 5 is adhered to the stent 2 and its size is adapted to the radial stent 2. The stent 2 can be folded into the groove at a softening temperature of 10°C. After the sterilization plug is placed in the int...

Embodiment 3

[0014] Embodiment 3: The sterilization plug of the present invention is made of TiNi alloy, wherein the weight percentage of Ni is 57.3%, and the balance is Ti. The sterilization plug includes a guide rod 1 and six radial stents 2 connected around the guide rod 1, and a film 5 is adhered to the stent 2. The cross section of the guide rod 1 and the film 5 adhered to the support 2 is round. The guide rod 1 has a length of 10 mm and a diameter of 1.8 mm, and each radial stent 2 has a length of 3 mm and a thickness of 0.5 mm. On the surface of the guide rod 1 at least one side close to the bracket 2 is provided with a groove 3 surrounding the guide rod 1. The length of the groove 3 is 3 mm, and the diameter of the guide rod 1 where the part of the groove 3 is located is 1.3 mm. The film 5 is adhered to the stent 2 and its size is adapted to the radial stent 2. The stent 2 can be folded into the groove at a softening temperature of 10°C. After the sterilization plug is placed in the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com