Numerical control wire ranging device and method thereof

The technology of a cable arrangement device and a limit device is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc. It can solve the problems of easy failure, complex mechanism, low precision, etc., and achieve easy maintenance and not easy damage , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the drawings:

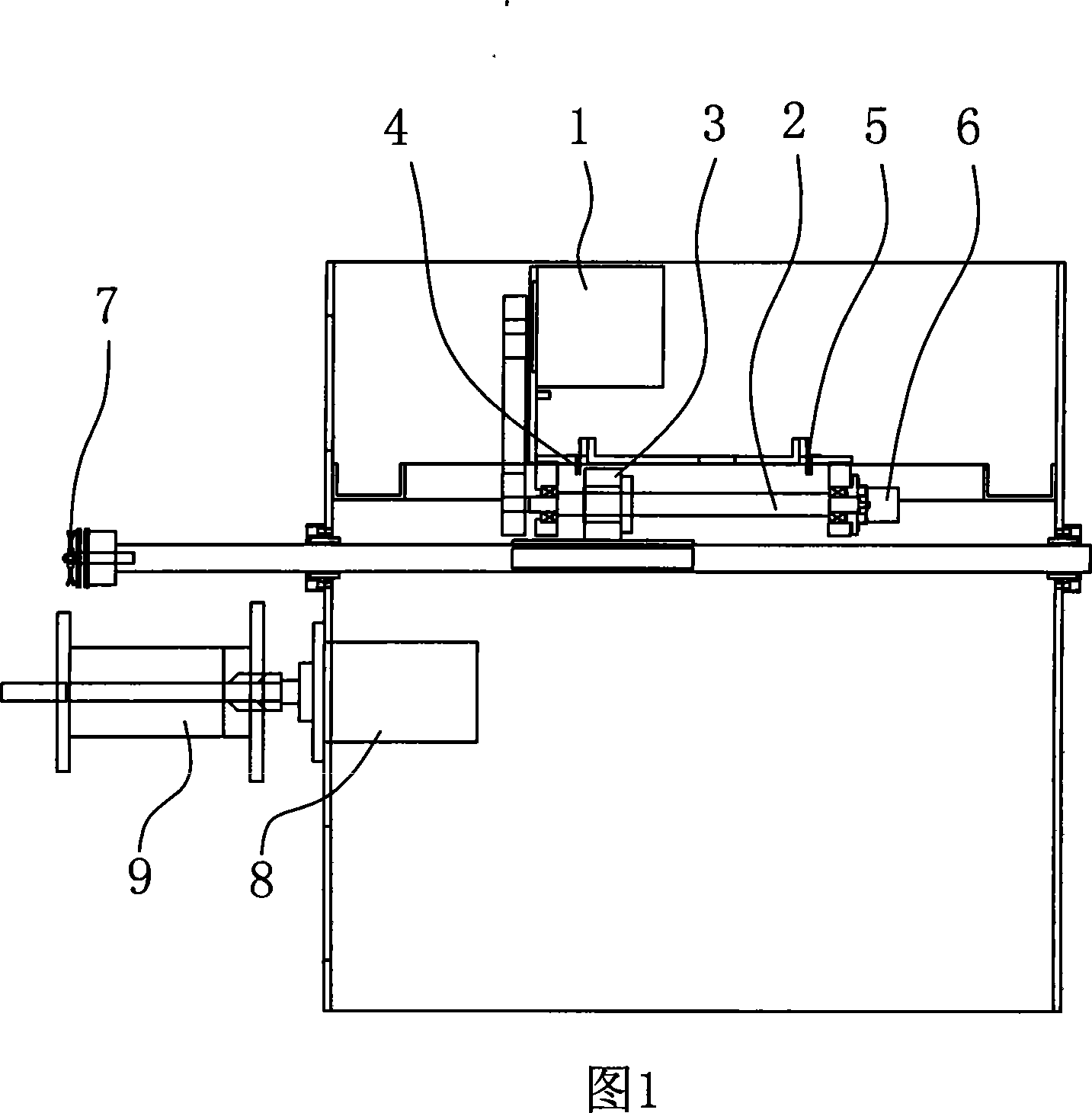

[0022] As shown in Figure 1, a numerical control cable arrangement device includes a motor 1, a screw rod 2, a screw rod mother 3, a forward rotation limit device 4, a reverse rotation limit device 5, and an encoder 6; the motor 1 follows the wire The rod 2 is connected in transmission, and the screw rod 2 is connected with the screw rod female 3. The two sides of the screw female 3 are respectively provided with a positive rotation limit device 4 and a reverse rotation limit device 5, and the screw female 3 is connected with a cable guide The wheel 7 and the wire guide wheel 7 are correspondingly provided with a wire take-up disk 9 driven by a wire take-up motor 8, and the encoder 6 is at one end of the screw rod 2. Motor 1 is connected with a frequency converter, and motor 1 is a synchronous motor; it is convenient for speed regulation and control of its operation.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com