Dustproof loop for conus type cracking machine

A technology of cone crusher and dust-proof ring, which is applied in grain processing and other directions, and can solve the problems of loss of sealing function, large friction coefficient, and easy wear and loss of sealing joint surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

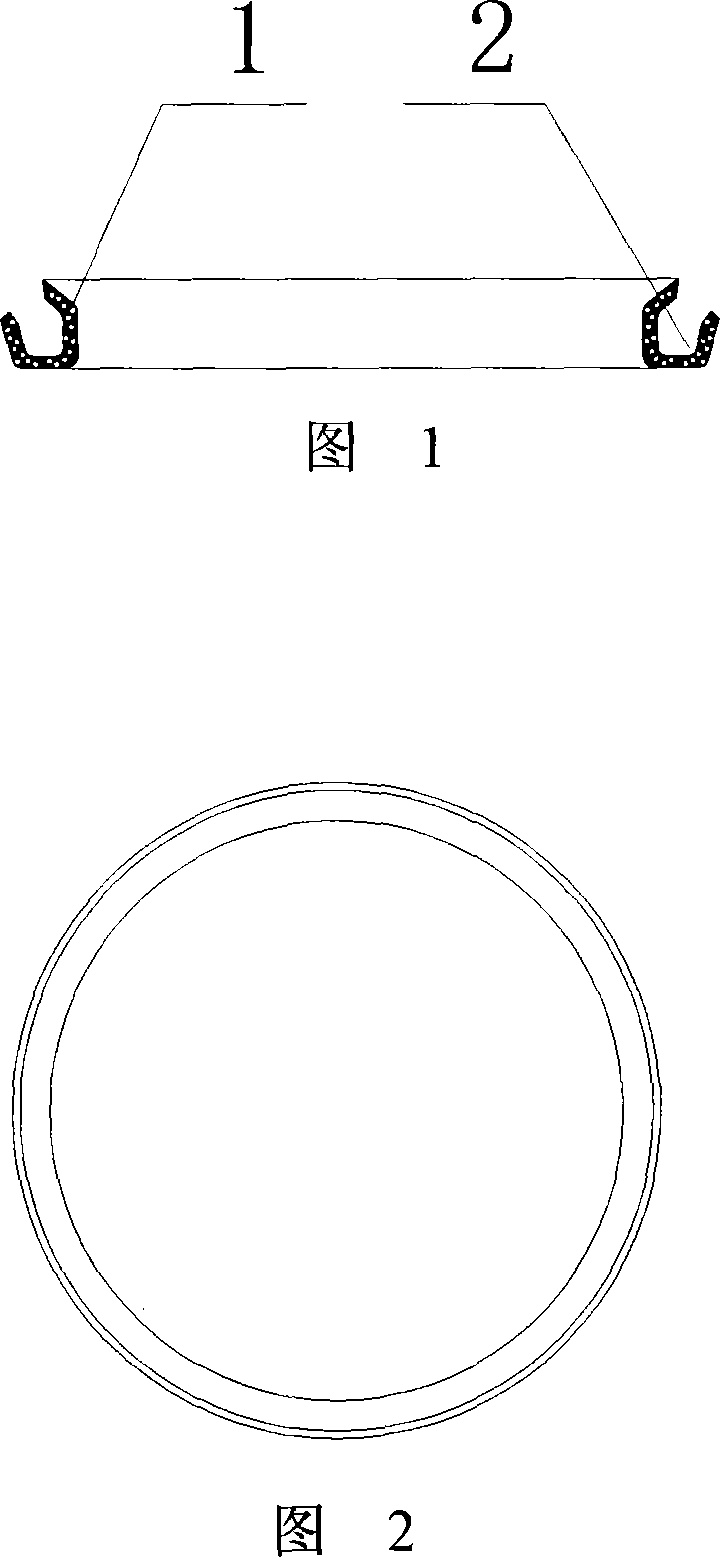

[0022] Embodiment 1: with reference to accompanying drawing 1. A dust-proof ring for a cone crusher, the material of the dust-proof ring is cast iron, and the composition and weight percentage range of the cast iron material are: 91.2% iron, 4.8% graphite and 4% silicon. Its production method: add 4.8% graphite and 4% silicon in turn to 91.2% molten iron to make it fully melted in the molten iron, then cast it in the mold cavity of the dust-proof ring, and cool it down.

Embodiment 2

[0023] Embodiment 2: with reference to accompanying drawing 1. A dust-proof ring for a cone crusher, the material of the dust-proof ring is cast iron, and the composition and weight percentage range of the cast iron material are: 92.6% iron, 4.4% graphite and 3% silicon. Its production method: add 4.4% graphite and 3% silicon in turn to 92.6% molten iron to make it fully melted in the molten iron, then cast it in the molding sand mold cavity of the dust-proof ring and cool it down.

Embodiment 3

[0024] Embodiment 3: with reference to accompanying drawing 1. A dustproof ring for a cone crusher, the material of the dustproof ring is cast iron, and the composition and weight percentage range of the cast iron material are: 92% iron, 4.6% graphite and 3.4% silicon. Its production method: 92% molten iron, add 4.6% graphite and 3.4% silicon in sequence to make it fully melted in the molten iron, then cast it in the molding sand mold cavity of the dust-proof ring, and then it can be cooled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com