Secondary hole sealing device for firedamp taking-out discharging drilling

A secondary sealing and gas drainage technology, which is applied in the direction of gas discharge, safety devices, earthwork drilling, etc., can solve the problems of difficult gas drainage work and the decrease of gas drainage concentration, so as to achieve ideal sealing effect and improve The effect of drainage gas concentration and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

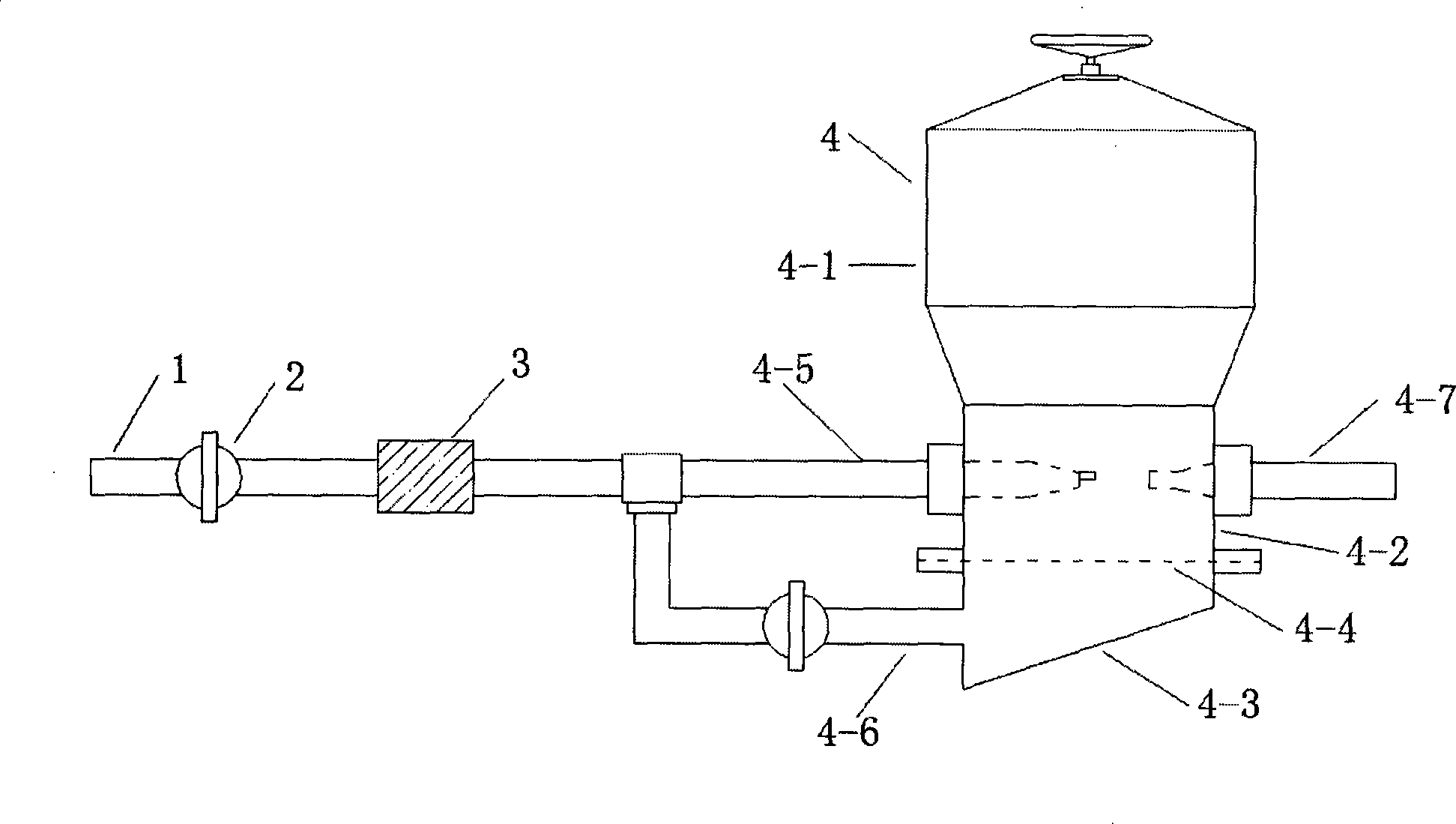

[0010] An example of the present invention will be further described below in conjunction with the accompanying drawings:

[0011] As shown in the drawings, the gas drainage drilling secondary sealing device of the present invention is composed of a main intake pipe 1, a control valve 2, a pressure reducing valve 3, and a feeding device 4. The control valve 2 and the pressure reducing valve 3 are arranged in sequence On the pipeline connecting the main air inlet pipe 1 and the feeding device 4, the feeding device 4 consists of a charging barrel 4-1, a blowing chamber 4-2 and an auxiliary air inlet chamber 4 arranged below the charging barrel 4-1. 3 composition, the bottom plate of the auxiliary air inlet chamber 4-3 is inclined to enhance the upward airflow. Between the blowing chamber 4-2 and the auxiliary air inlet chamber 4-3 is provided with a barrier breathable canvas 4-4, and the blowing chamber 4-2 is respectively provided with a blowing air inlet pipe 4-5 and a discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com