Liner tube type electromagnetic repairing method for old pipe

A repair method and pipeline technology, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve problems such as easy peeling, pipe perforation, liquid medium pollution, etc., and achieve easy electromagnetic parameters, high structural strength, and improved The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

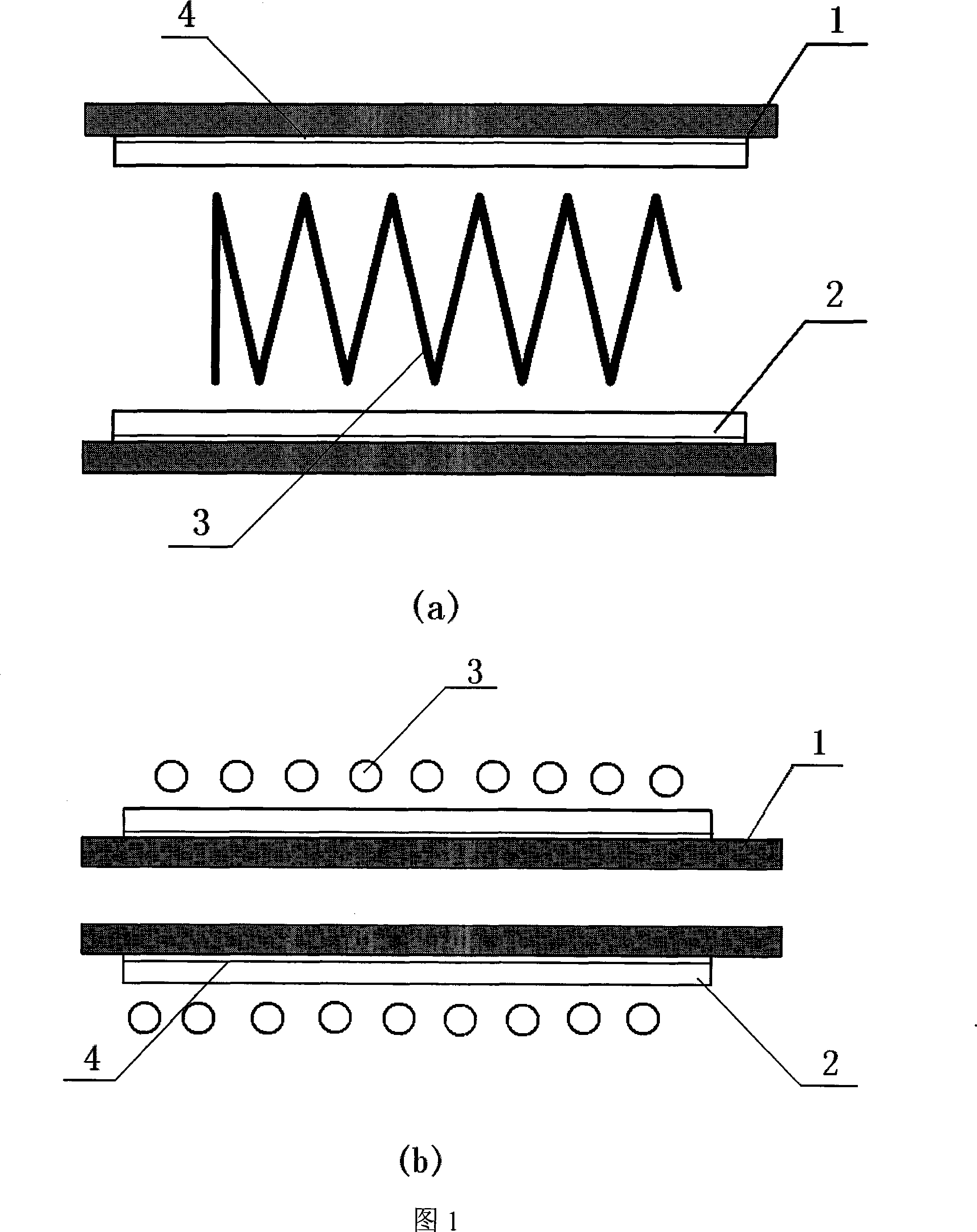

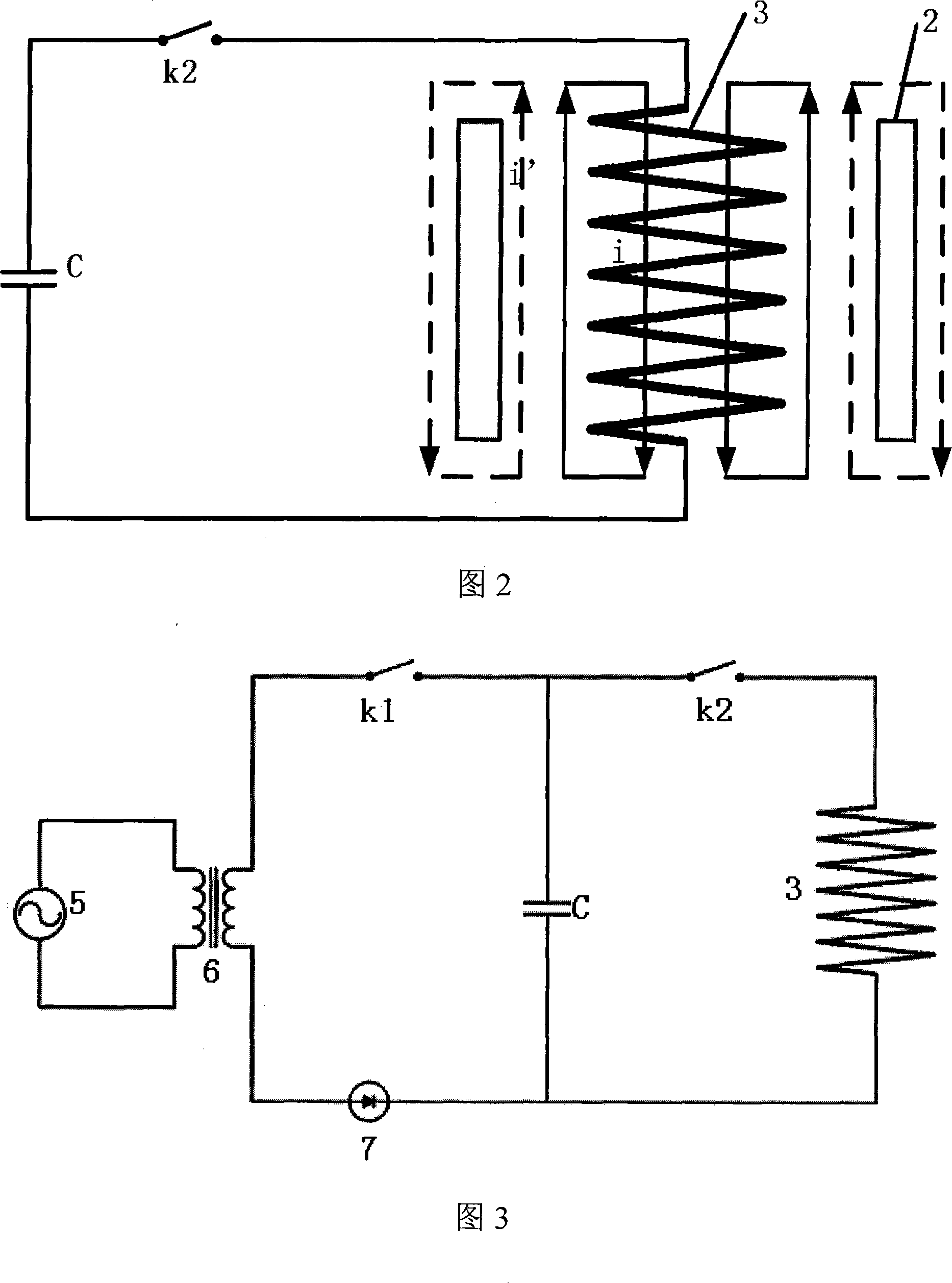

[0025] Embodiment 1: A cast iron pipe for drainage with an inner diameter of 50 mm and a wall thickness of 5.5 mm is repaired with a liner pipe. The coil 3 is 65 mm long and 45 mm in outer diameter and placed inside the liner pipe 2 . The liner 2 is made of 2A12 aluminum alloy, with an outer diameter of 48mm and a wall thickness of 0.5mm. The total length of the repair is 140mm. During this period, a total of 4 discharges were performed. After the repair was completed, a hydraulic test was carried out. The test water pressure was 0.4MPa, and no seepage was found after 3 minutes. Leakage phenomenon, in line with the original pipeline standards.

Embodiment 2

[0026] Embodiment 2: Using an outer liner to repair a buried pipeline with an outer diameter of 48 mm and a wall thickness of 4 mm and made of 20 steel. The coil 3 is 60 mm long and 55 mm in inner diameter and placed outside the liner 2 . The liner 2 is made of 304 stainless steel, with an inner diameter of 50mm and a wall thickness of 0.4mm. The total length of the repair is 120mm. During the period, a total of 4 discharges were performed. After the repair was completed, the 10MPa water pressure test was used, and no leakage was found, which was in line with the original pipeline standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com