Biological diesel fuel and preparation thereof

A biodiesel and oil technology, which is applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, petroleum industry, etc., can solve the problems of poor quality and poor oxidation stability, and achieve the effect of low cost and obvious application benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

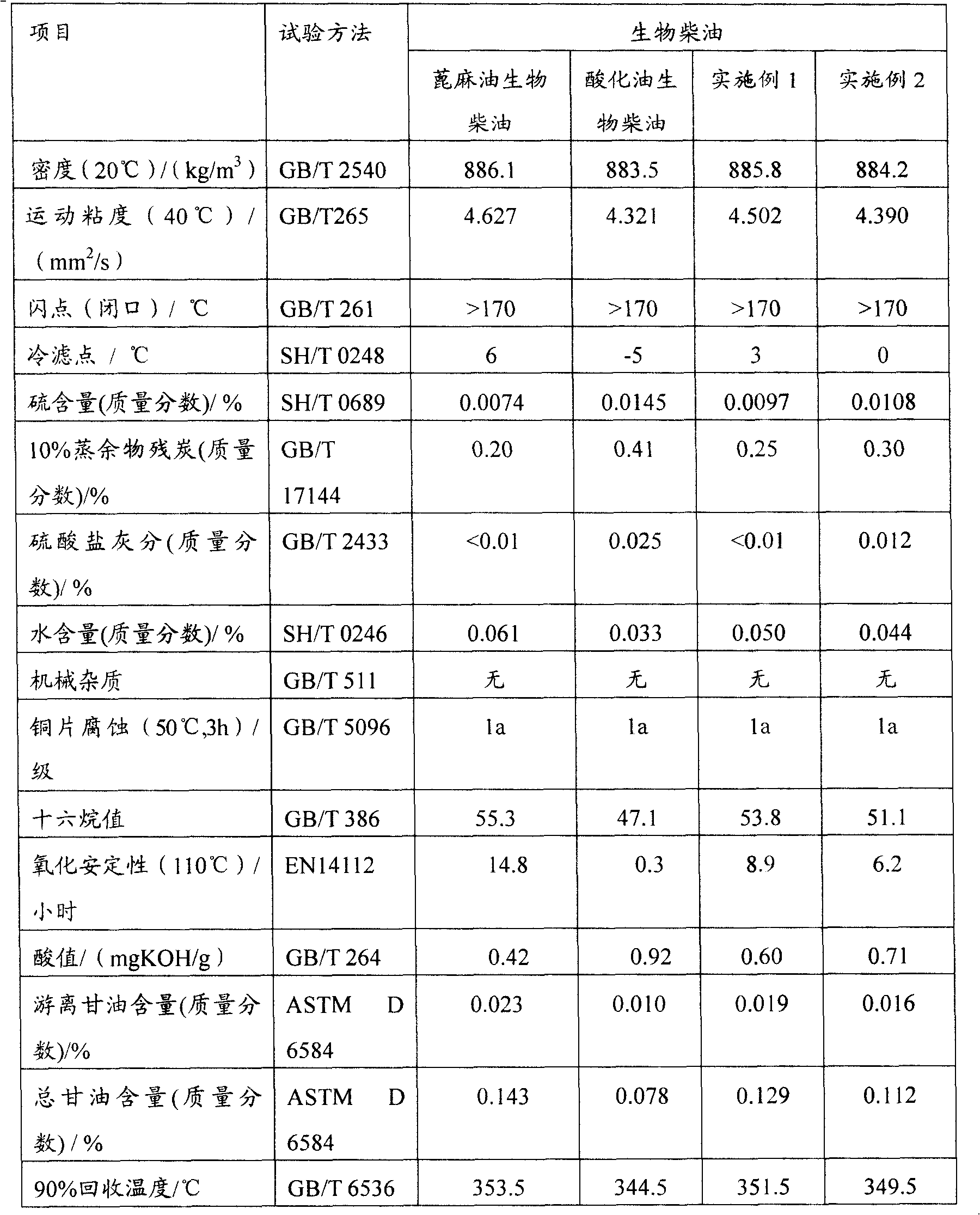

[0033] This embodiment illustrates the production of biodiesel (iodine value 84.5gI) with castor oil 2 / g) and biodiesel produced from acidified oil (iodine value 110.9gI 2 / g) After blending, biodiesel with improved oxidation stability and low-temperature fluidity can be obtained. Example 1 is a biodiesel blended by castor oil biodiesel and acidified oil biodiesel with a volume ratio of 3:1; embodiment 2 is a blend of castor oil biodiesel and acidified oil biodiesel with a volume ratio of 1:1 produced biodiesel. Its performance is shown in Table 1.

[0034] It can be seen from Table 1 that the biodiesel produced from castor oil has good oxidation stability but poor low-temperature fluidity, while the biodiesel produced from acidified oil has poor oxidation stability but good low-temperature fluidity. After blending, Example 1 and Example 2 The oxidation stability and low-temperature fluidity of the corresponding biodiesel are improved at the same time, meeting the requireme...

Embodiment 3~5

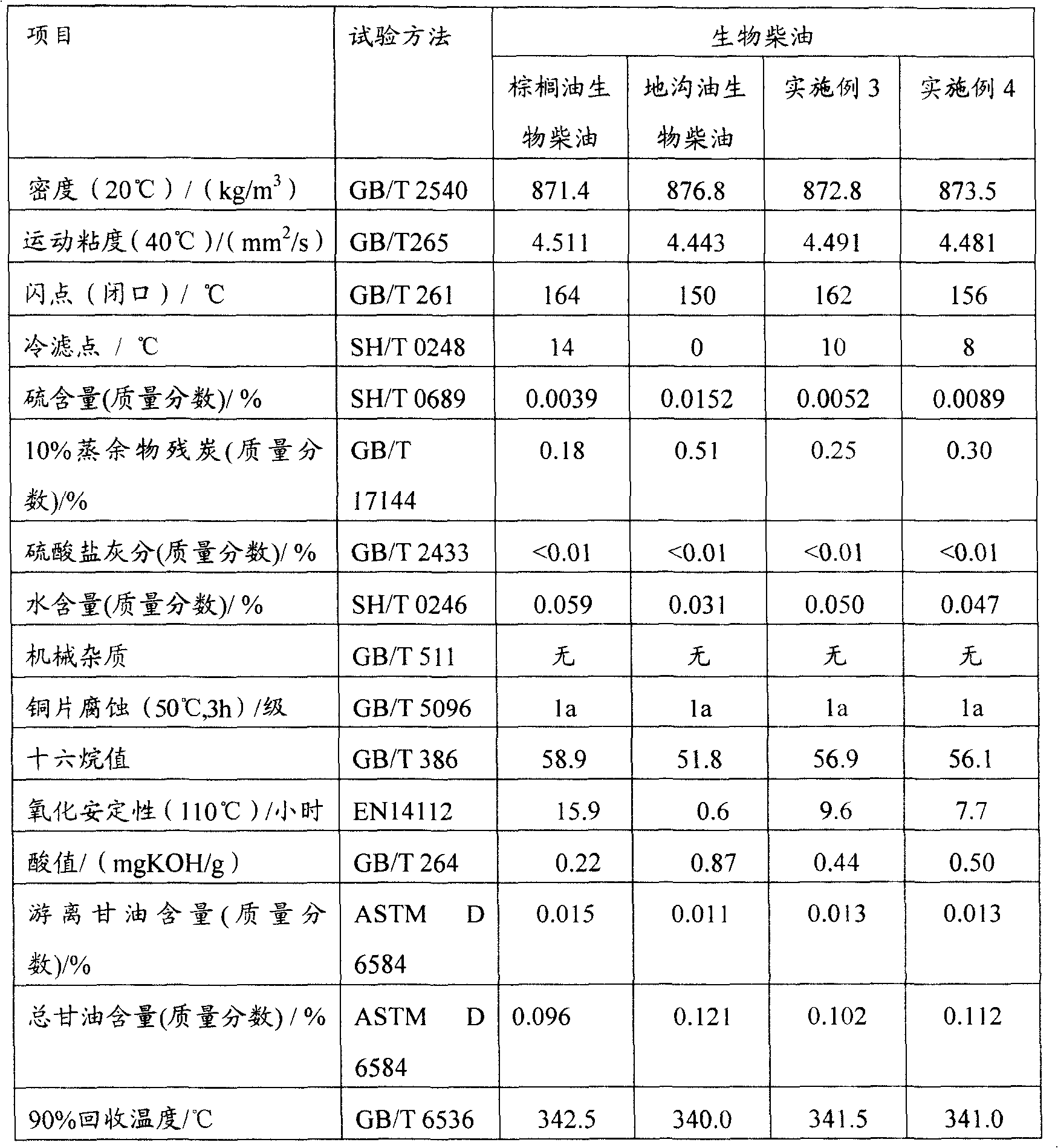

[0038] This example illustrates biodiesel produced from palm oil (iodine value 49.6gI 2 / g) and biodiesel produced from waste oil (iodine value 109.8gI 2 / g) After blending, biodiesel with improved oxidation stability and low-temperature fluidity can be obtained. Embodiment 3 is the biodiesel blended by palm oil biodiesel and waste oil biodiesel with a volume ratio of 3:1; embodiment 4 is blended with palm oil biodiesel and waste oil biodiesel with a volume ratio of 3:2 The properties of the biodiesel produced are shown in Table 2.

[0039] Table 2

[0040]

[0041] As can be seen from Table 2, the biodiesel produced from palm oil has good oxidation stability, but poor low-temperature fluidity, while the biodiesel produced from waste oil has poor oxidation stability. The oxidation stability of the biodiesel corresponding to Example 3 and Example 4 after blending Stability and low temperature fluidity are improved at the same time, meeting the standard requirements. At t...

Embodiment 5

[0043] In this embodiment, different raw materials are mixed in advance and biodiesel meeting the standard requirements is produced by a supercritical method (referring to the method disclosed in CN1594504A).

[0044] Palm oil (iodine value 47.5gI 2 / g) and acidified oil (iodine value 107.5gI 2 / g) After mixing according to the volume ratio of 2:1, take 60g of mixed oil, put it into the autoclave together with 120g of methanol, heat the autoclave to 250°C, the autoclave pressure gauge shows 11.8MPa, maintain the temperature for half an hour, wait Cool the high-pressure reactor to 50°C, pour out the reactants, distill off excess methanol (recyclable), centrifuge to separate the generated glycerin, wash with dilute alkali solution three times, then wash with distilled water, and finally obtain biological Diesel oil 40g, analyze its performance as shown in table 3.

[0045] table 3

[0046] project

[0047] It can be seen from Table 3 that with the pre-mixed raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com