Tunnel inner micro-destabilization slip-casting technique

A micro-disturbance technology in the tunnel, applied in tunnels, tunnel linings, wellbore linings, etc., can solve problems such as formation disturbances, inability to take into account the surrounding complex environment, and disturbance of the speed of pipe pulling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

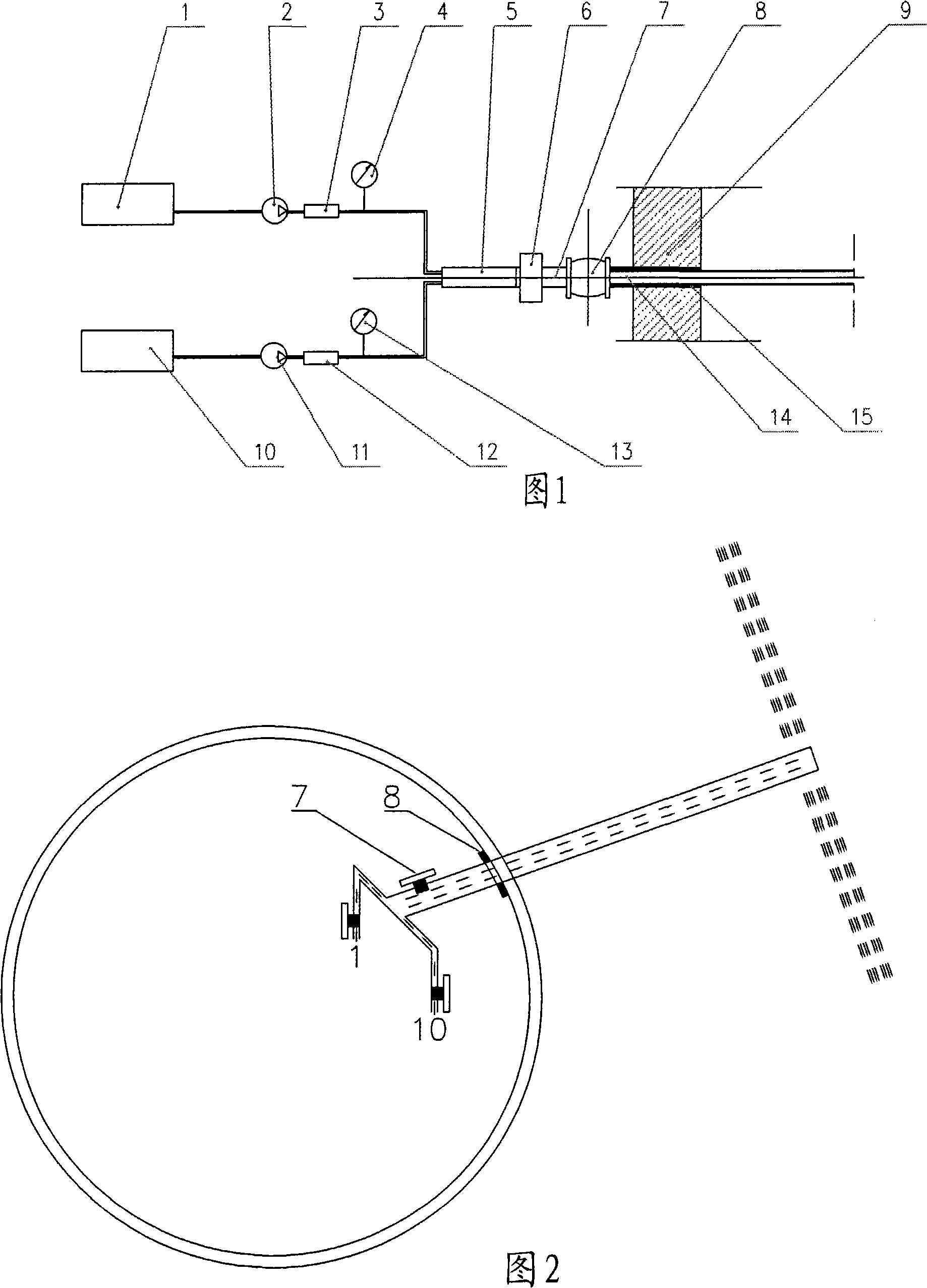

[0013] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

[0014] As shown in Figure 1-2, the labels 1-15 represent: liquid A mixing tank 1, liquid A grouting pump 2, flow meter 3, pressure gauge 4, mixing chamber 5, sealing device 6, one-way valve 7, ball valve 8. Shield segment 9, liquid B mixing tank 10, grouting pump 11, flow meter 12, pressure gauge 13, grouting pipe 14, shield segment embedded parts 15.

[0015] The grouting materials and process parameters used in this embodiment are as follows:

[0016] (1) Double liquid slurry ratio

[0017] In order to minimize the impact of the grouting process on the inclined house and the surrounding environment, according to different geological conditions and construction experience, the grout ratio with a shrinkage rate of less than 5% is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com