Heat pipe radiator and high-power LED road lamp

A technology for LED street lamps and cooling devices, which is applied in cooling/heating devices, lighting devices, fixed lighting devices, etc. Very good, the heat dissipation area of the heat sink is not large enough, etc., to achieve the effect of simple structure, easy processing and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

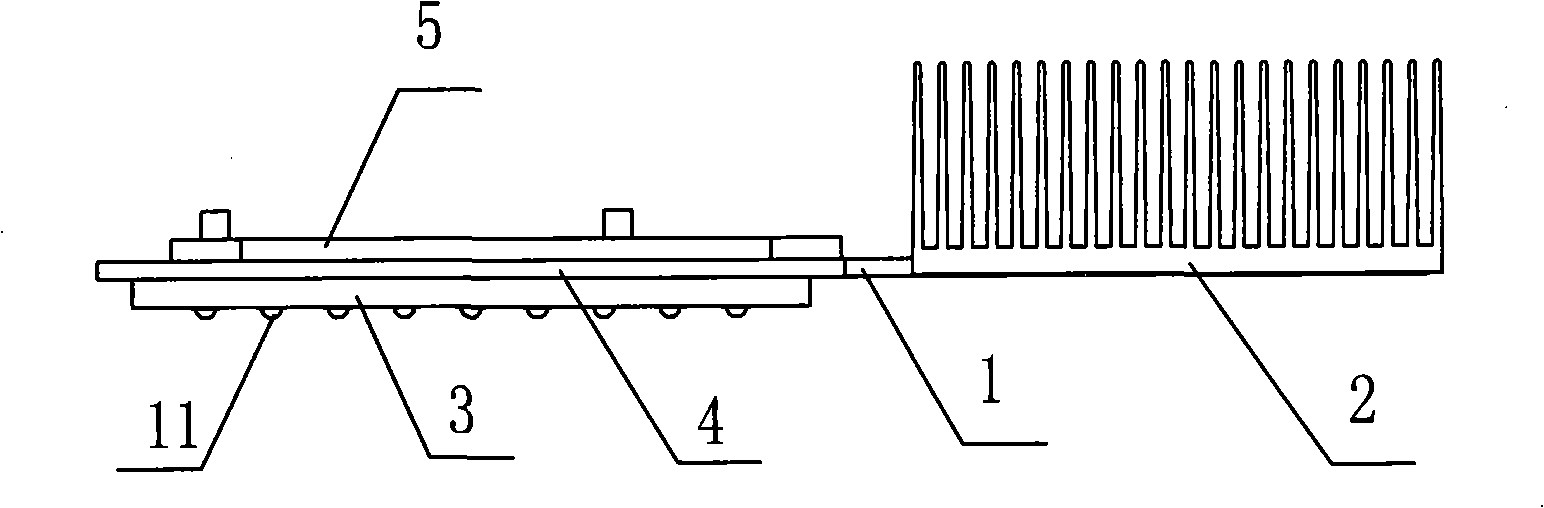

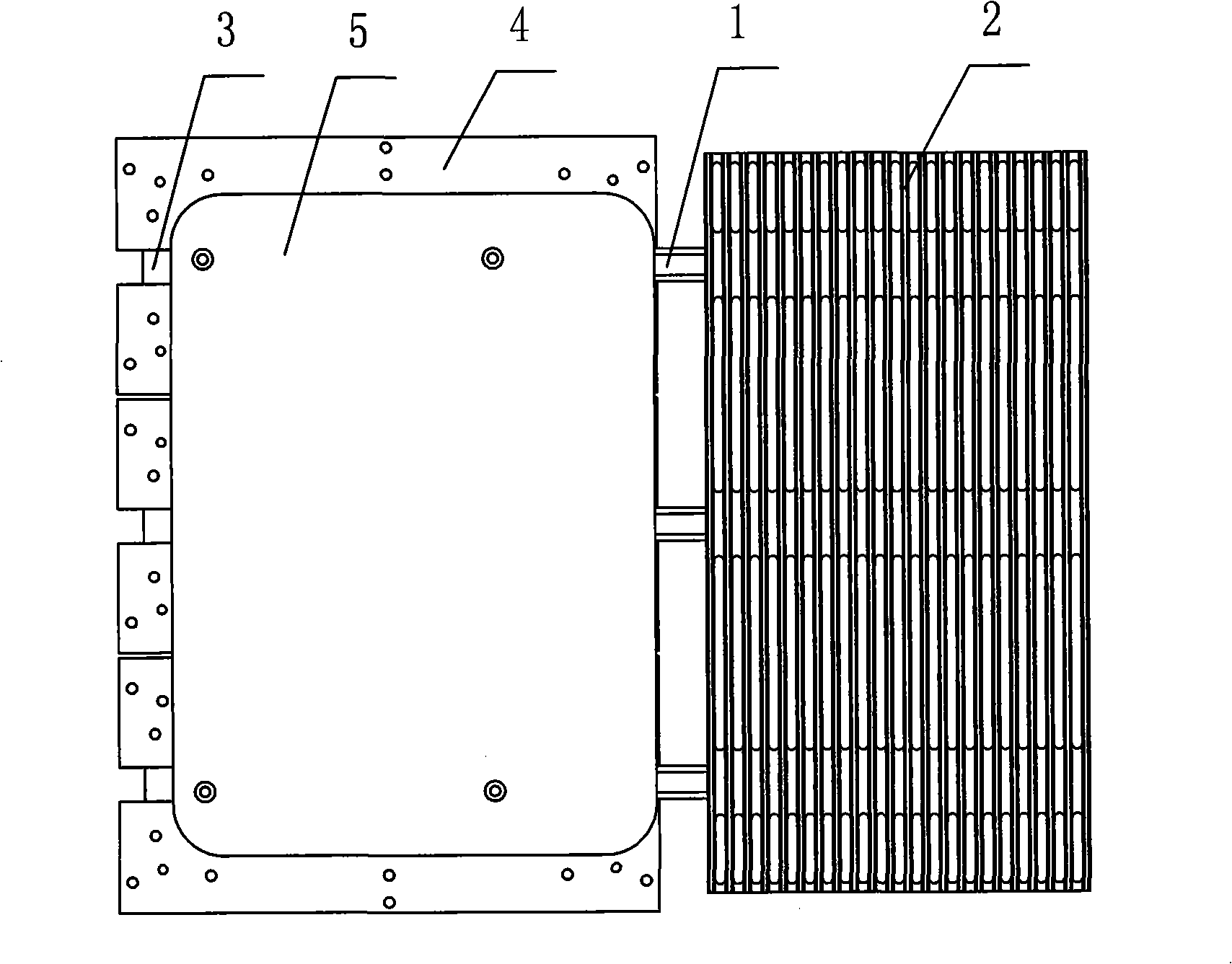

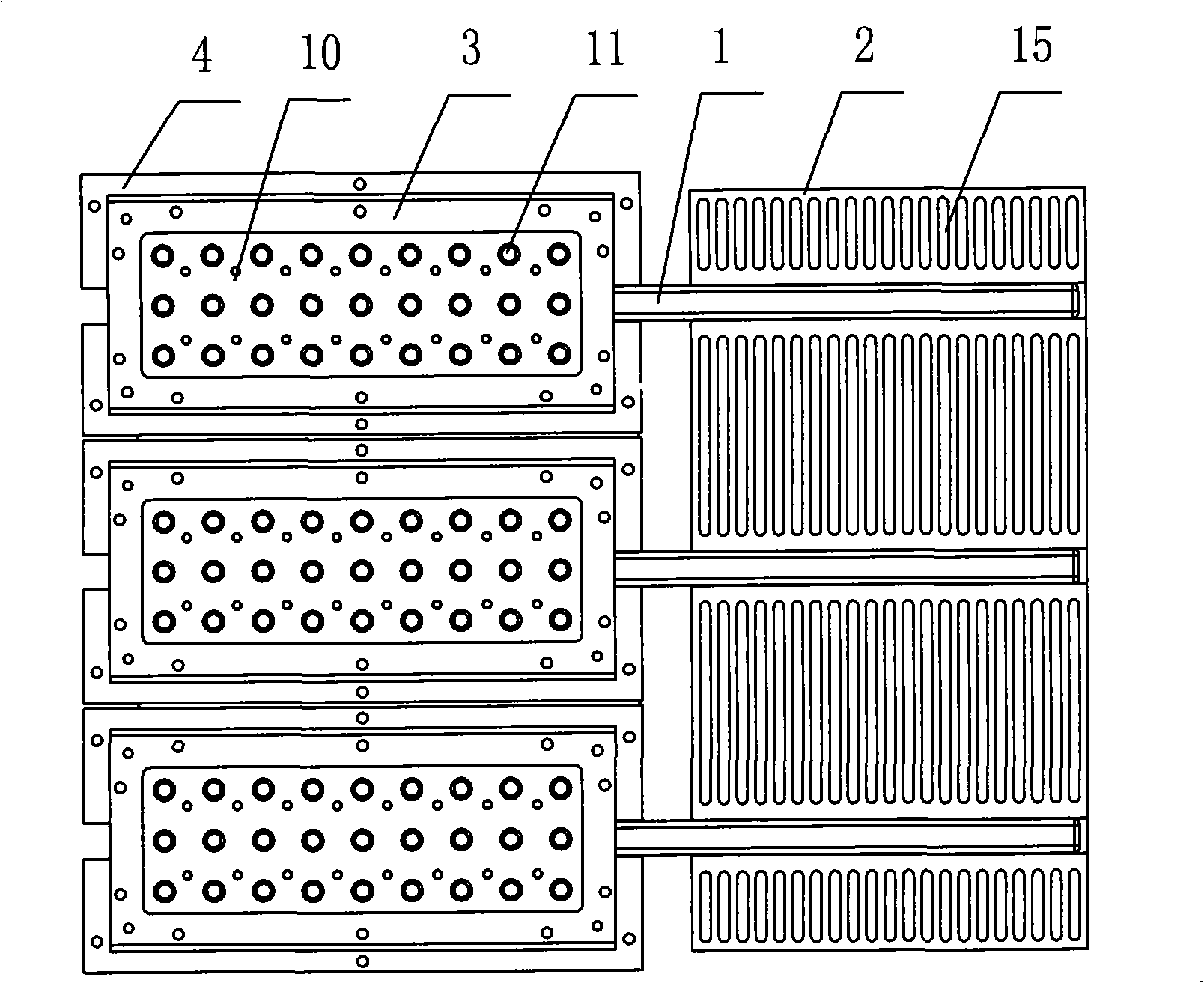

[0029] see Figure 1 to Figure 11 , in the figure, the heat pipe cooling device includes a heat transfer plate, a heat pipe 1 and a heat sink 2, one end of the heat pipe 1 is fixedly connected to the heat transfer plate, the other end of the heat pipe 1 is fixedly connected to the heat sink 2, and the heat transfer plate consists of three aluminum substrates The fixed plate 3, six intermediate fixed plates 4 and the heat pipe pressure plate 5 are stacked together and fixedly connected. The middle fixed plate 4 is located between the aluminum substrate fixed plate 3 and the heat pipe pressure plate 5. One end of the heat pipe 1 is installed on the In the groove formed by the two intermediate fixing plates 4 , the other end of the heat pipe 1 is installed in the groove at the bottom of the heat sink 2 .

[0030] The inside of the heat pipe 1 is sealed with a low boiling point liquid. The inner wall of the heat pipe contains a capillary liquid-absorbing core layer. The heat pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com