Packaging structure of plane waveguide light shunt and preparation method thereof

A technology of planar waveguide and optical splitter, which is applied in the field of optical fiber, can solve the problems of difficult use process, packaging and transportation, cumbersome manufacturing process, and large overall volume, and achieve the effects of being suitable for mass production, reducing manufacturing processes, and protecting optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

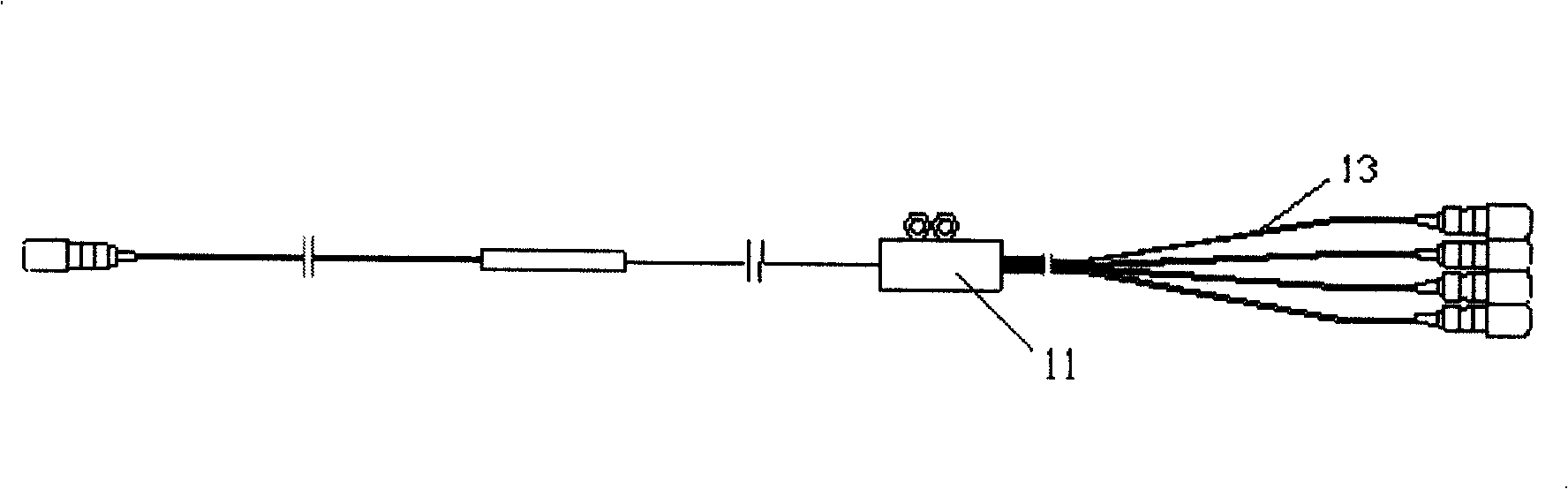

[0030] Embodiment: Below we describe the method of the present invention according to the packaging method of the 900 micron fiber sleeve output of the 1x8 planar waveguide optical splitter, but it should be understood that the method of the present invention is also applicable to other MxN planar waveguide optical splitters.

[0031] The present invention provides a packaging structure and packaging method of a planar waveguide optical splitter as follows:

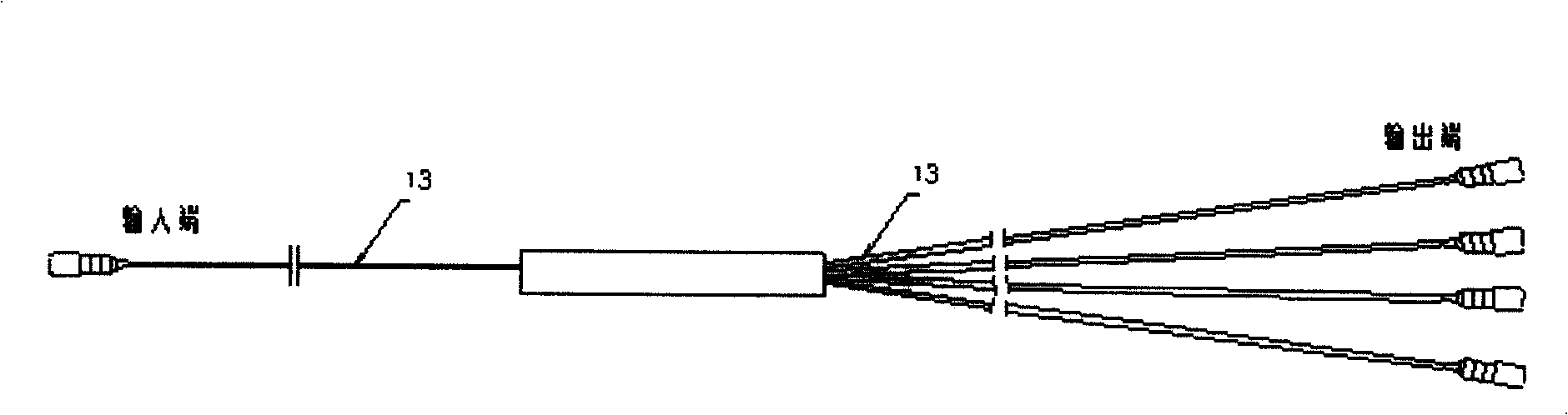

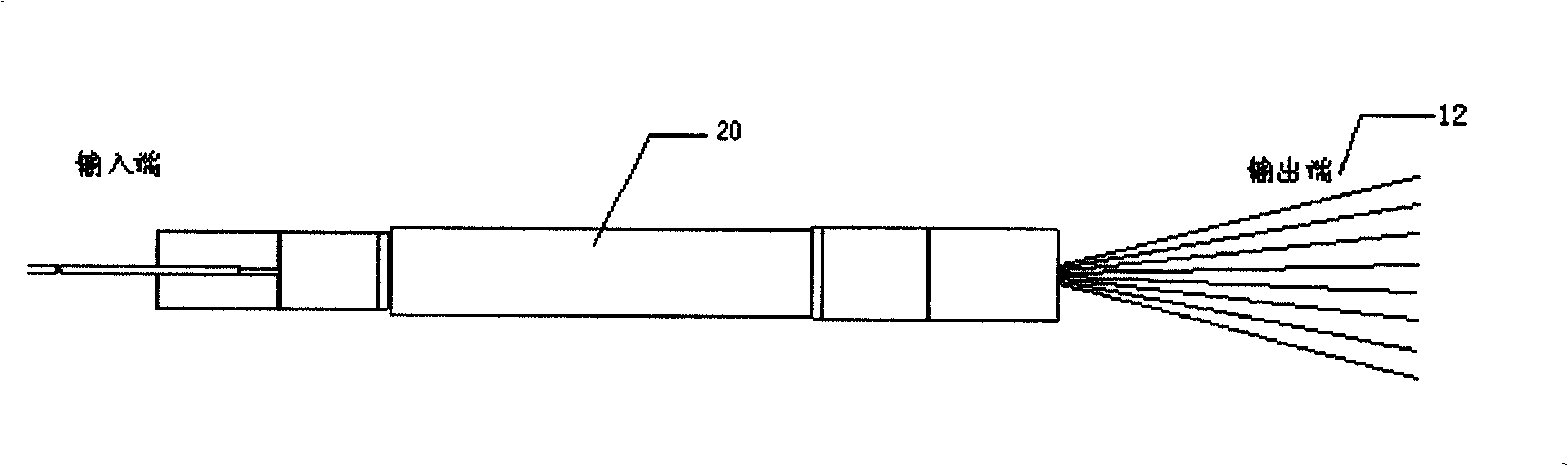

[0032] Step 1: If Figure 3A , splitting the output end (12) of the planar waveguide splitter core (20) into a single optical fiber;

[0033] Step 2: If Figure 3A , fixing the planar waveguide splitter core (20) on the working frame;

[0034] Step 3: If Figure 3B , the 900 micron loose tube (13) and the input end rubber cap (14) are fixed together to produce the input end rubber cap assembly (15);

[0035] Step 4: If Figure 3C , 8 900 micron loose tubes (13) at the output end and the output end rubber cap (16) are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com