Method for manufacturing multilayer printed wiring board

A technology of multi-layer printing and manufacturing method, applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems of reduced quality, complicated manufacturing process, damage of insulating resin layer, etc., to improve bending resistance and reliability. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in the embodiments described below, in order to simplify the description, a multilayer printed wiring circuit composed of a flexible part (lead pattern part) as one conductor layer and a multilayer part (laminated circuit pattern part) as four conductor layers The board is described as an example, but the laminated circuit pattern part is not limited to four conductor layers, and may have three conductor layers or other multilayer structures. In addition, it can be applied to multilayer printed wiring boards of all forms represented by common name build-up boards such as laser method / optical via method.

[0095]

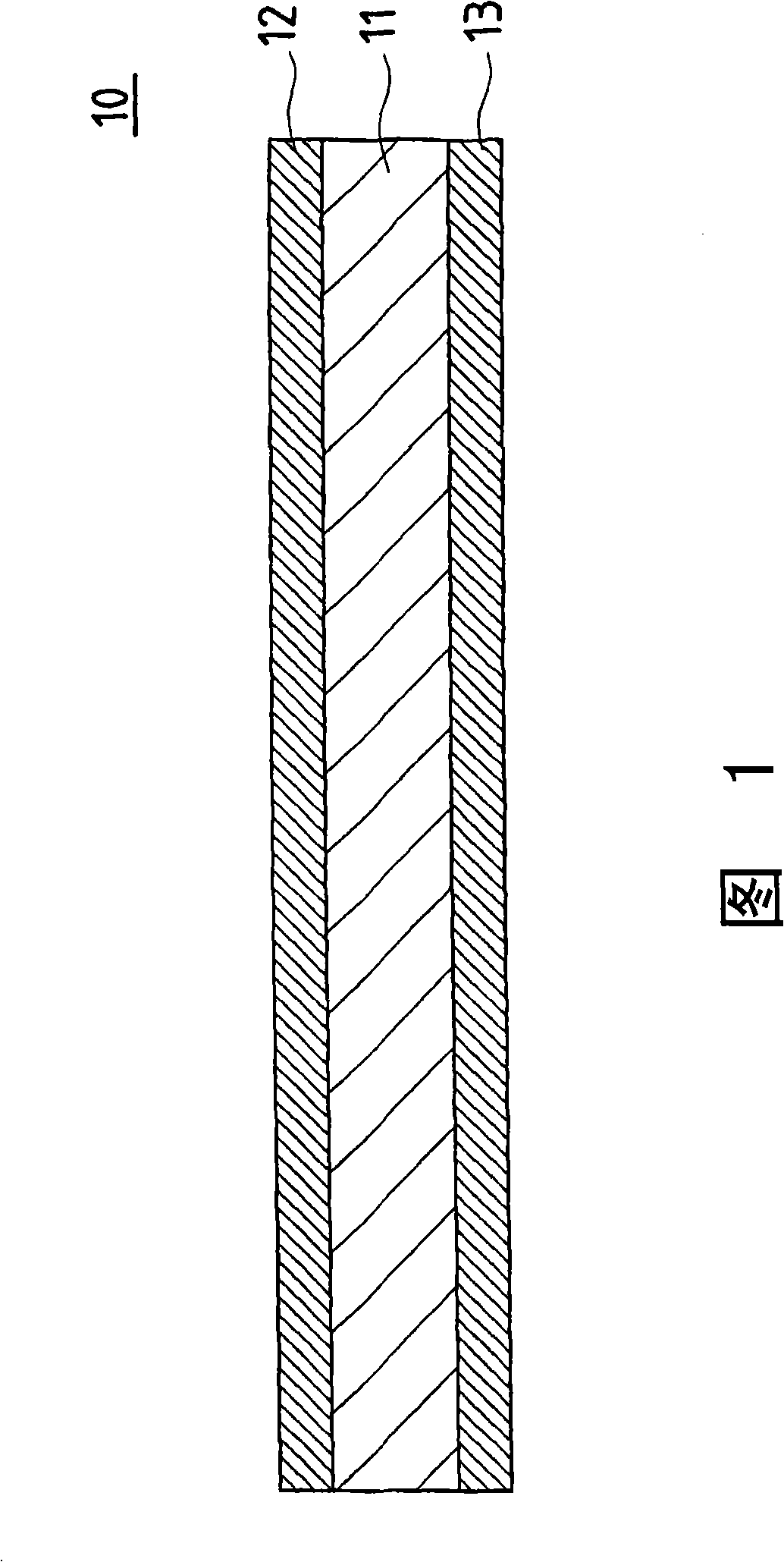

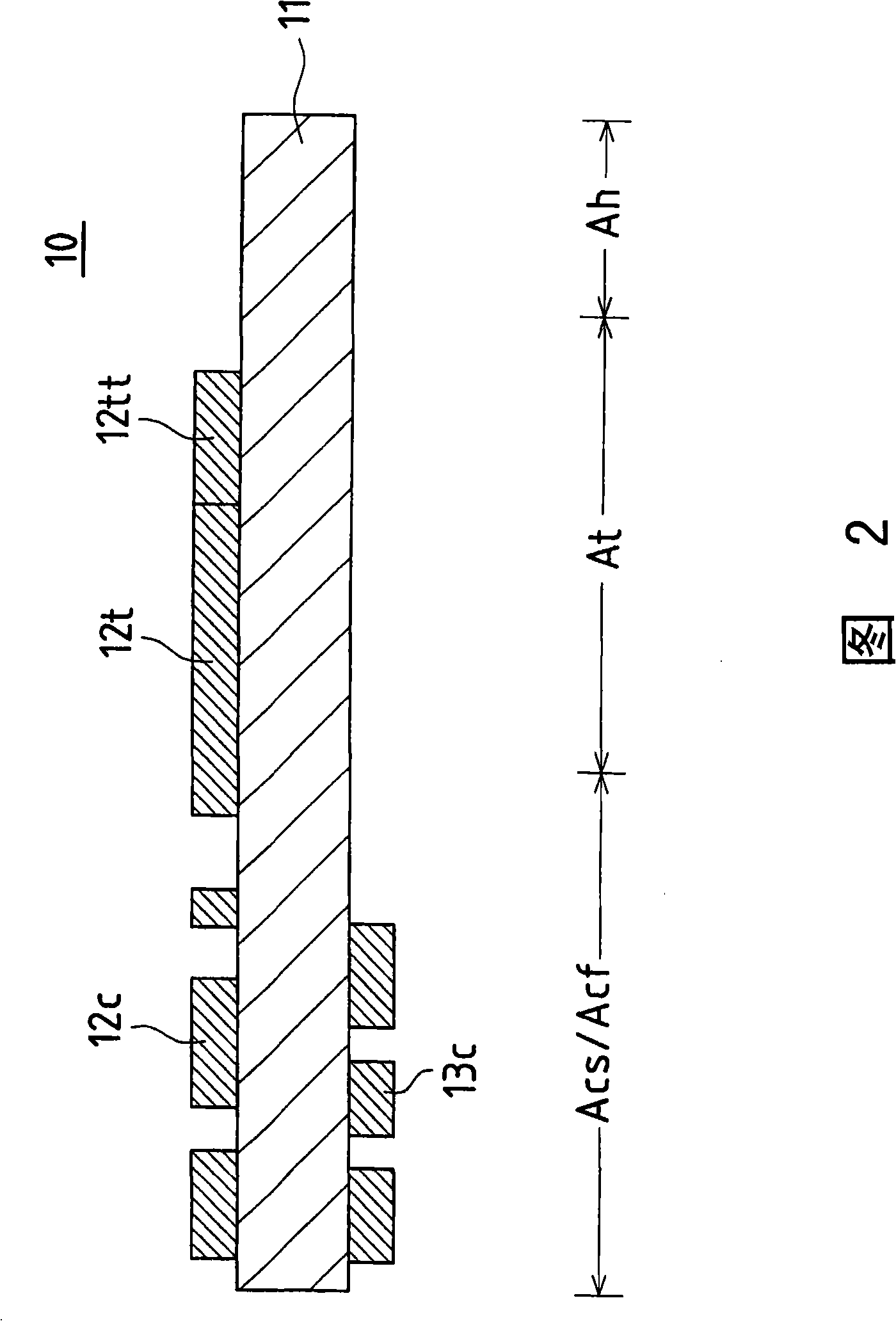

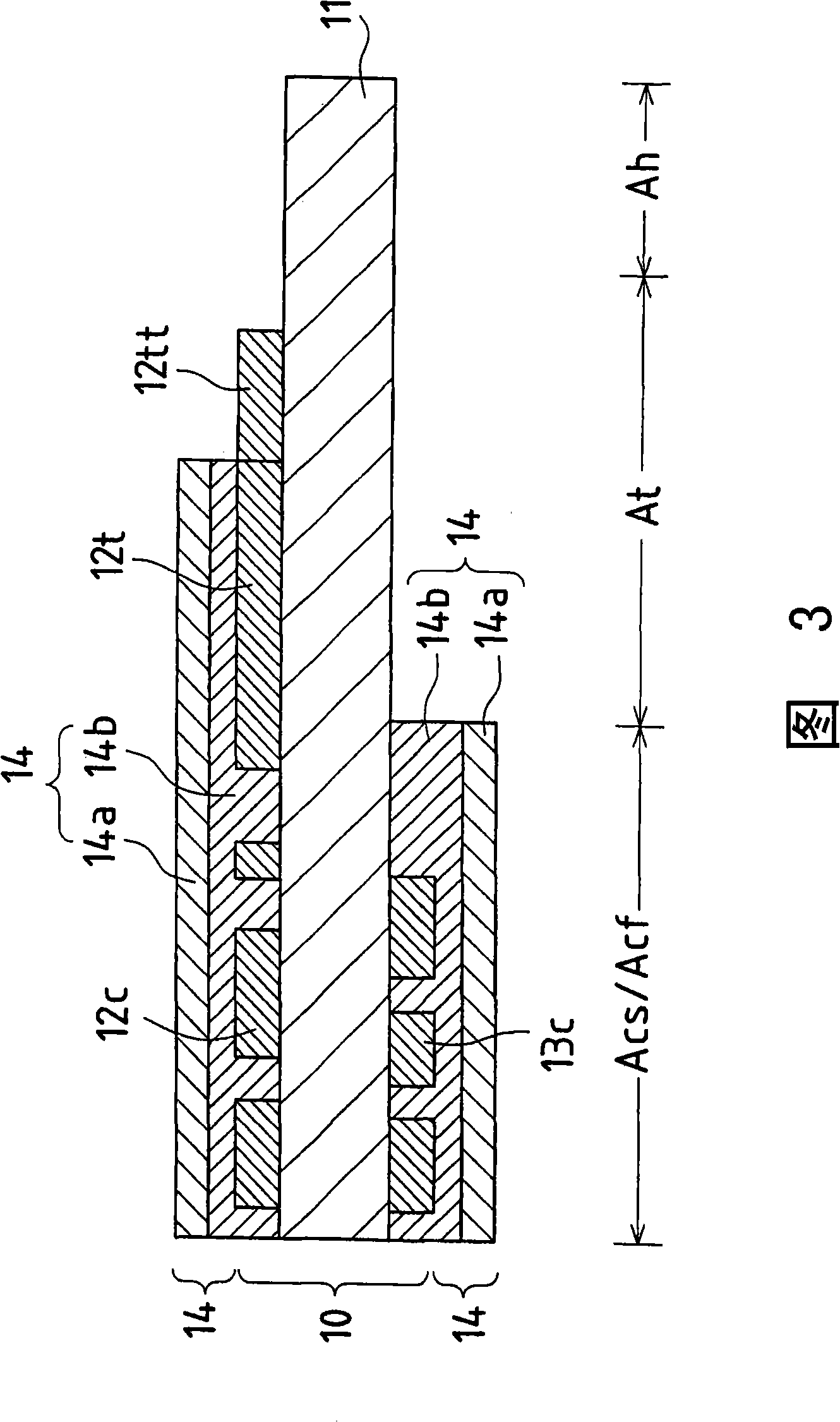

[0096] A method of manufacturing the multilayer printed wiring board according to the first embodiment will be described with reference to FIGS. 1 to 9 .

[0097] In the first embodiment, a multilayer printed wiring board in which a flexible lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com