Intensity of the fire controlling method and device

A heat and control system technology, applied in heating devices, electrical program control, program control in sequence/logic controllers, etc., can solve difficult problems such as heat and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

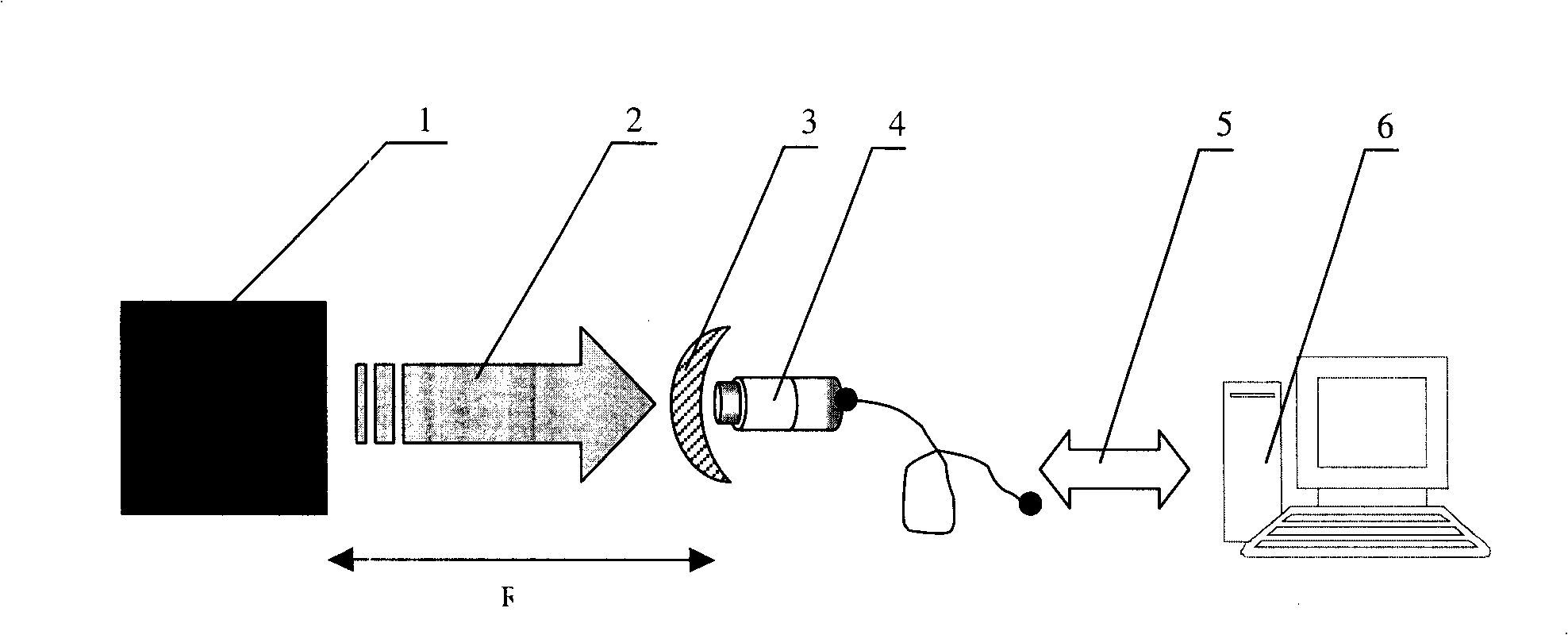

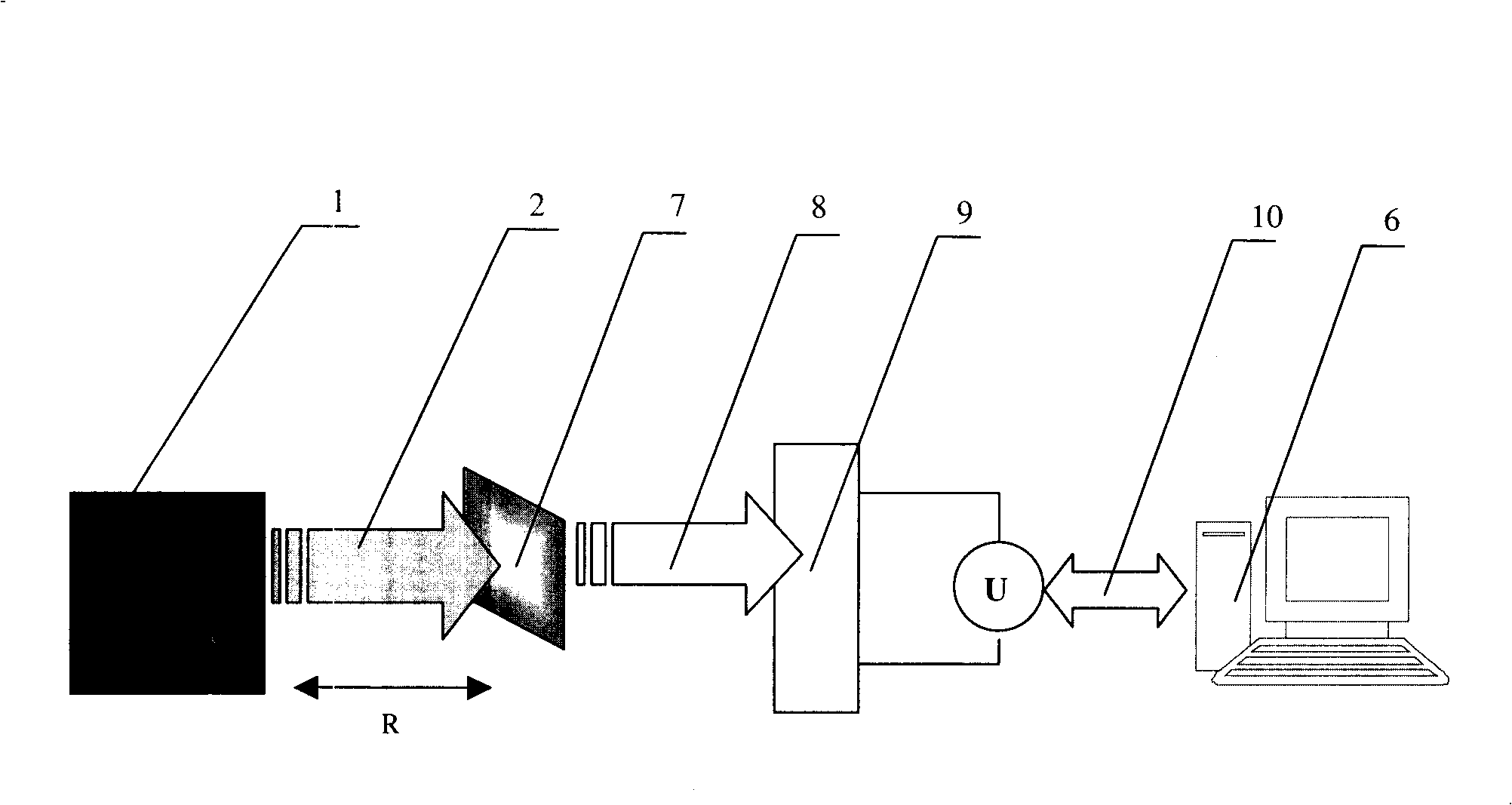

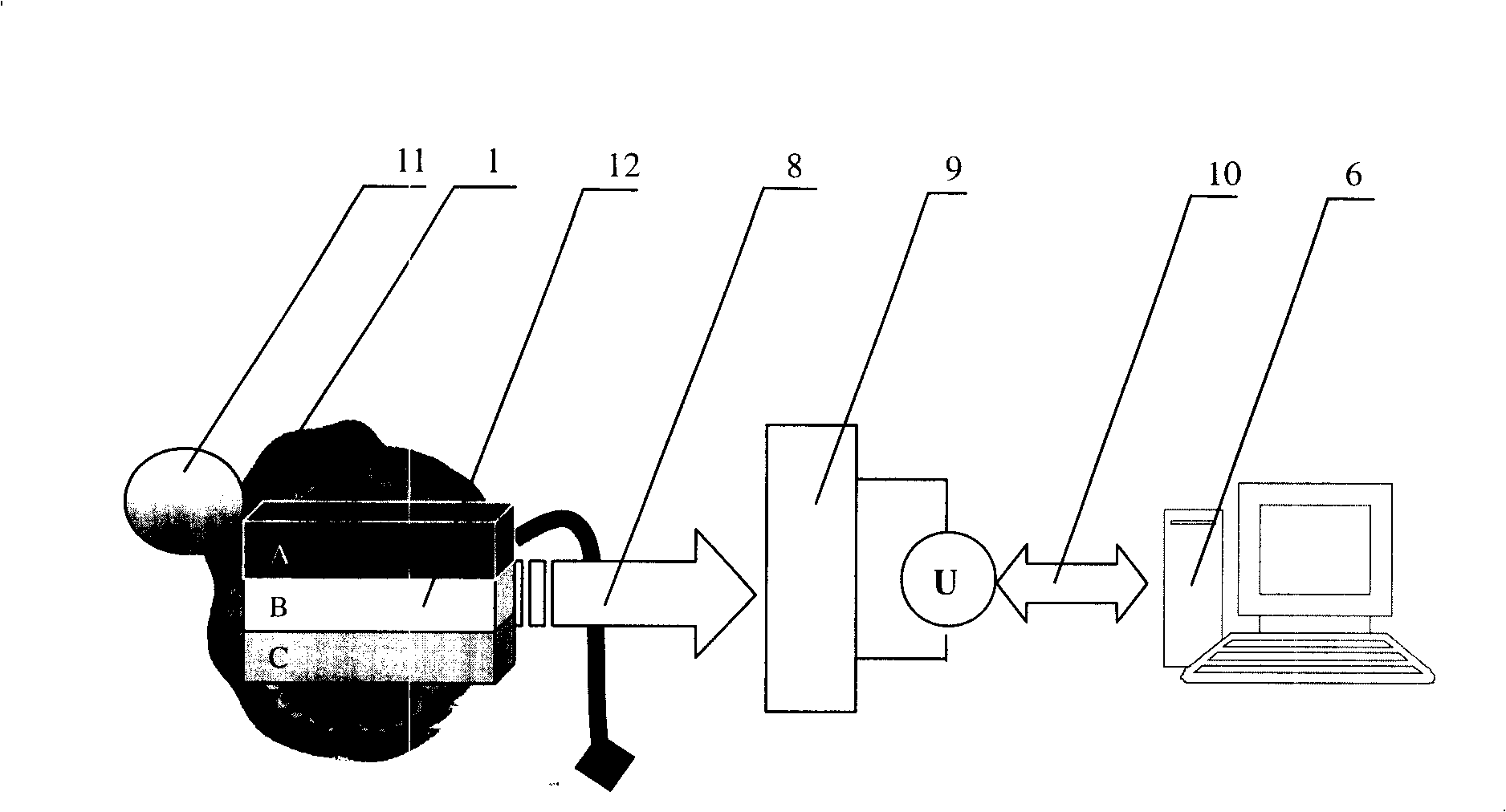

[0062] figure 1 It is a schematic diagram of an embodiment of a non-contact heating intensity measurement method of the present invention. This measurement method is also a kind of radiant heat measurement method, and the measured value is an instantaneous (real-time) value. In the figure, 1 is the heat source, 2 is the heat radiation emitted by the heat source, 3 is the Fresnel lens, 4 is the thermopile detection device, 5 is the detection signal, 6 is the control device of the cooking appliance, and R is the distance between the detection device and the heat source. space distance.

[0063] The sensing surface of the thermopile 4 is aimed at the flame to be measured through the Fresnel lens 3, so as to measure the radiant heat of the current flame. The output signal of the thermopile sensor is a voltage signal, which is related to the current thermal radiation power Φ R (unit Watt) is proportional to. By the formula Φ=K×Φ R The current firepower intensity (unit Watt) ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com