Organic refuse liquid state processing method and device

A technology for organic waste and treatment methods, applied in biochemical cleaning devices, biochemical equipment and methods, sterilization methods, etc., can solve problems such as incomplete methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

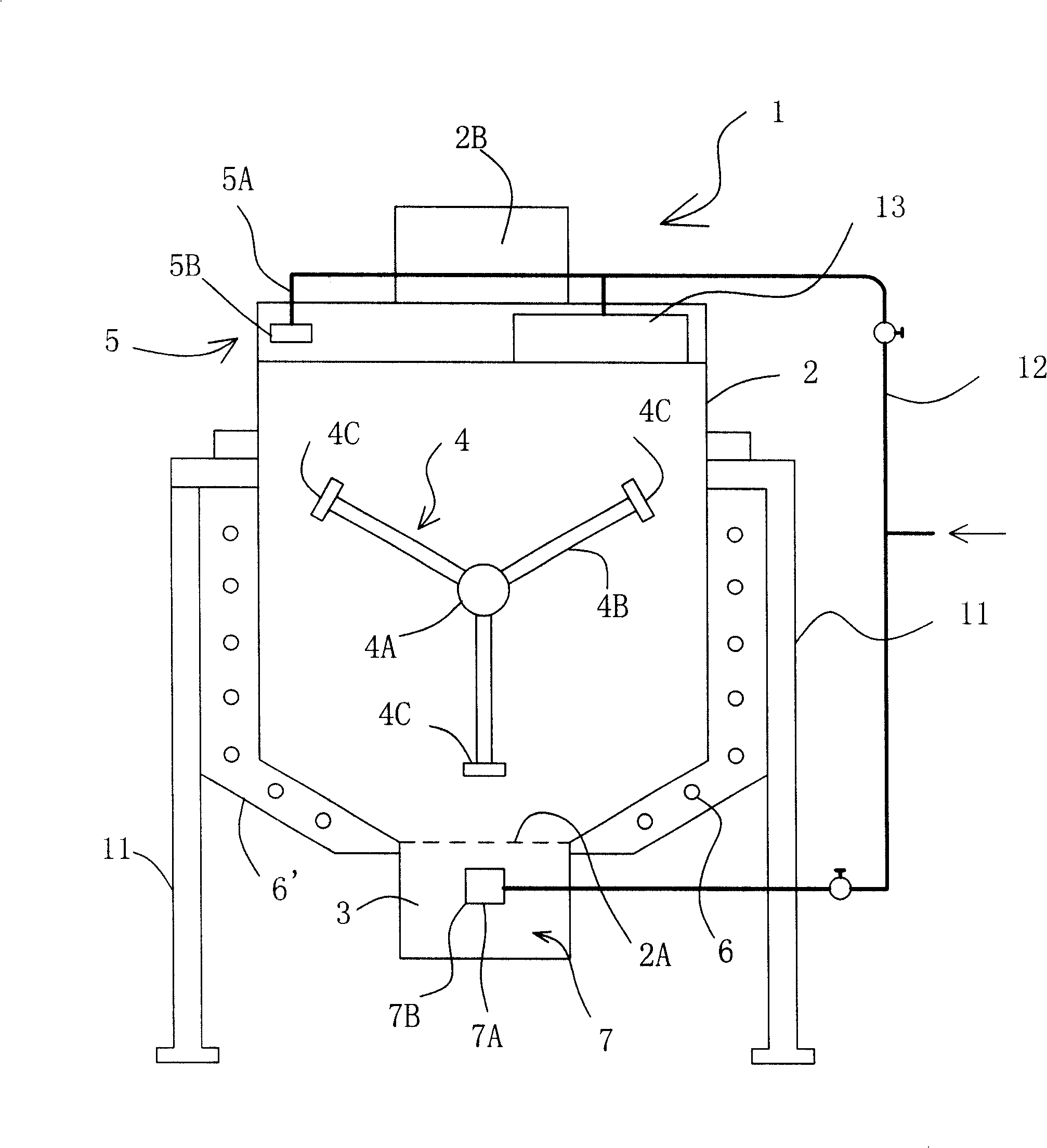

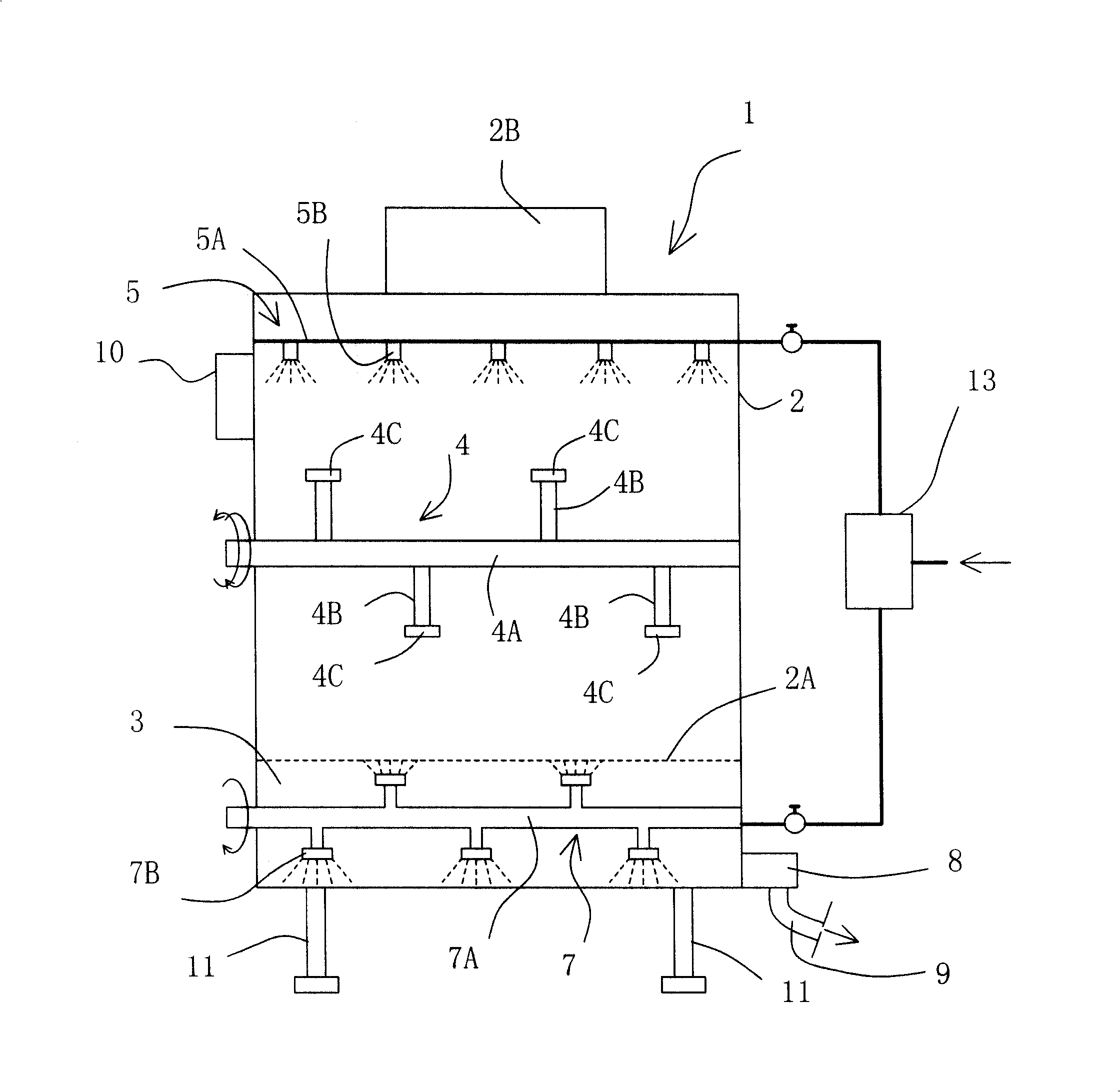

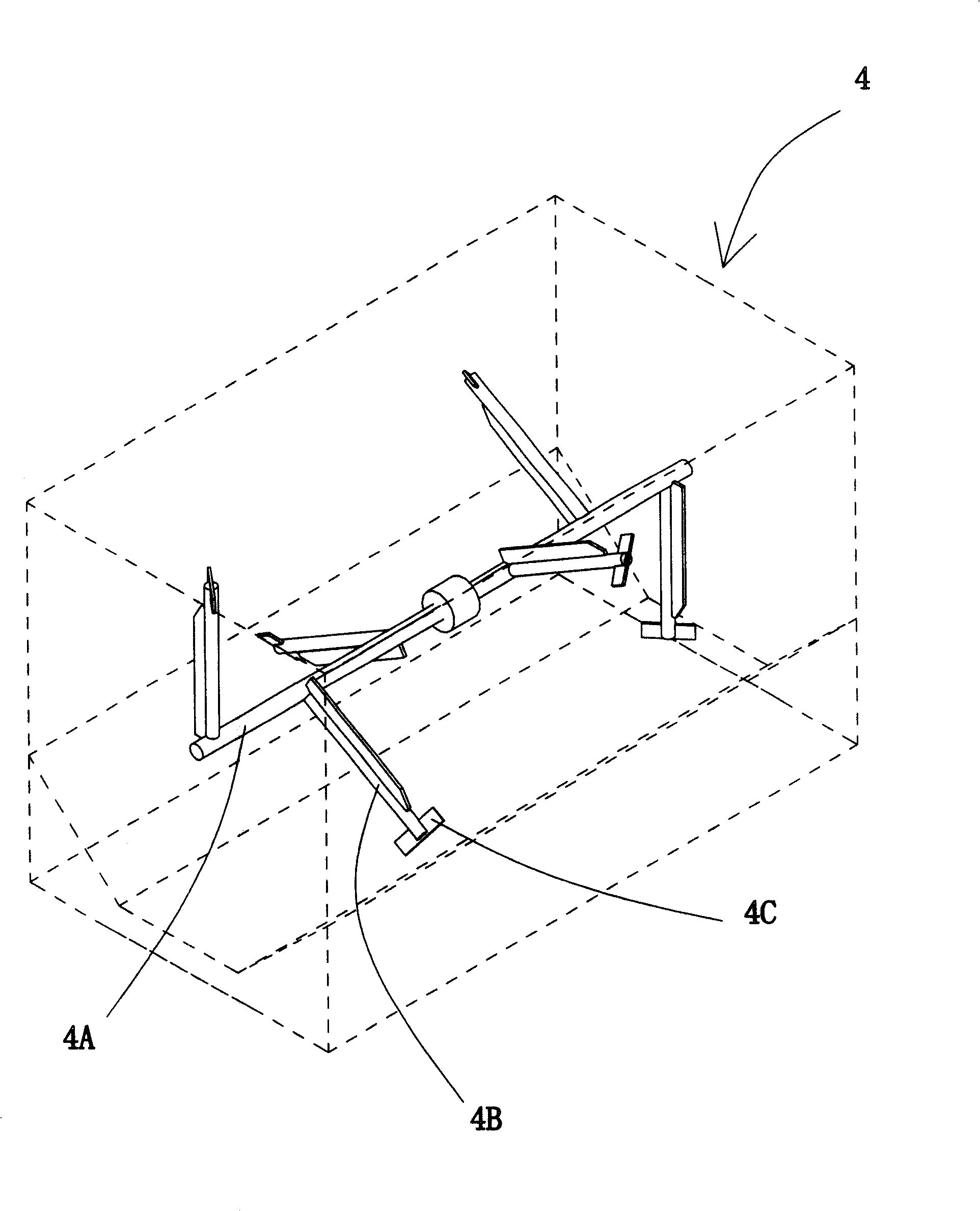

[0048] Such as figure 1 with figure 2 As shown, the cross-section and axial section of the organic waste liquefaction treatment device 1 of the present invention show its main structure, and two implementations of the location of the alkalized water generating components, that is, the alkali is set on the branch line of the water supply pipeline. A chemical water generating member and an alkalized water generating member are provided in the water supply pipe.

[0049] The invention discloses a liquefaction treatment method for organic waste, which is a method for discarding the organic waste after being transformed into a harmless and odorless liquid. Described organic waste liquefaction treatment method is to utilize a kind of organic waste liquefaction treatment device 1 to finish, and this method comprises following technological process (referring to figure 1 with figure 2 )

[0050] First, through the feeding part 2B of the device 1, no more than a specified amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com