Hermetic seal process for box body and pile body

A technology for sealing water-stopping and pile bodies, which is applied in construction and infrastructure engineering, etc., can solve problems such as poor water-stopping effect and sealing effect, difficulty in airbag placement and positioning, difficulty in checking the airtightness of airbags, etc., and achieve structural Simple, reliable water stop and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

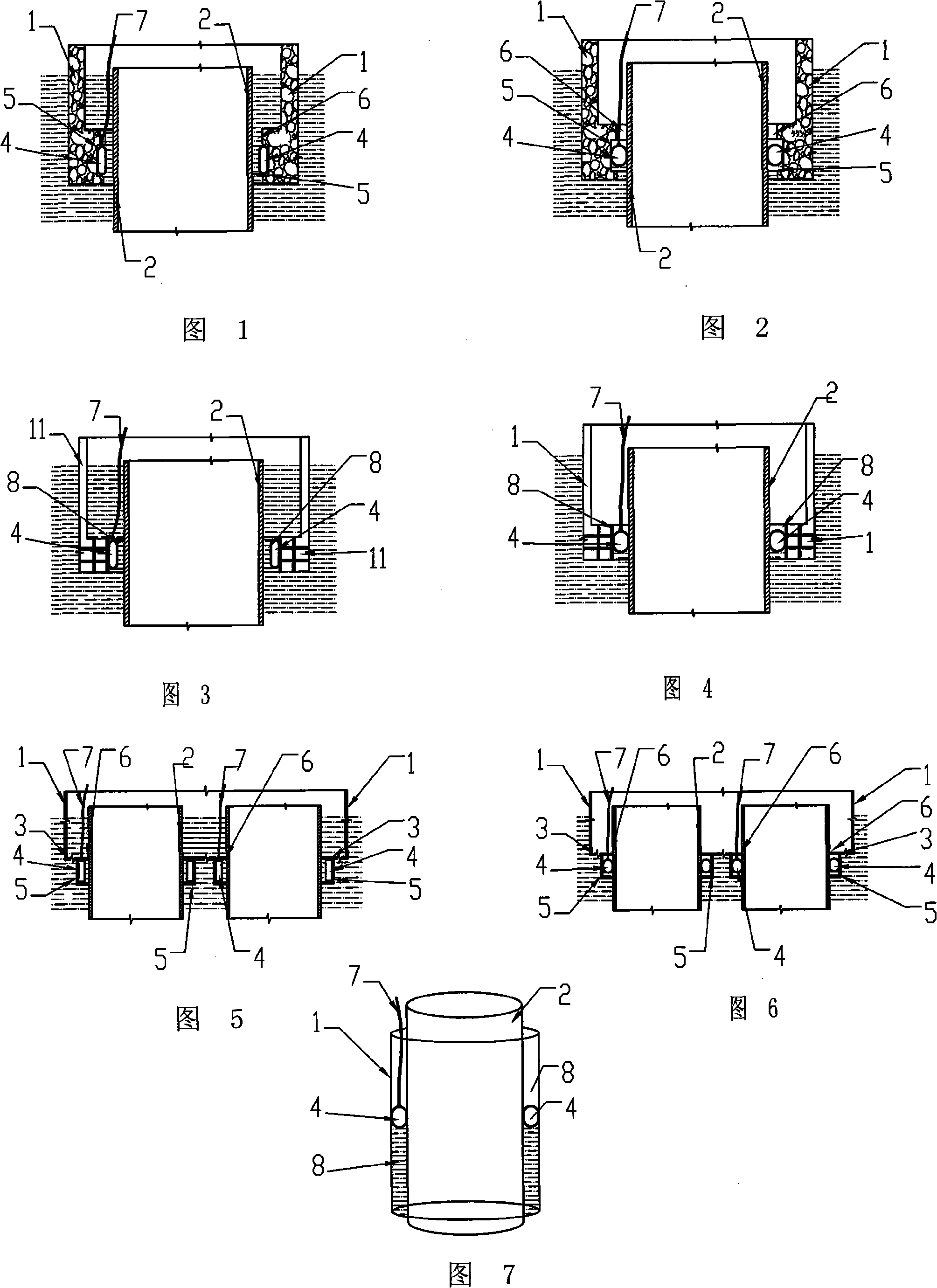

[0033] Embodiment 1, as shown in Figure 1, this method is to arrange base plate at the bottom of box body 1, base plate has pile hole 6 that accommodates pile body 2 to pass through, makes annular air bag groove 5 on the pile hole side wall of base plate, Pre-place an annular air bag 4 with a rectangular cross-sectional shape in the annular air bag groove 5. The inner diameter of the annular air bag is 5% larger than the outer diameter of the pile, as shown in Figure 2. The airbag is inflated, and when the air pressure reaches 0.4MPa, the airbag will close the gap when it is filled, realizing the purpose of completely stopping the water, and then the water in the box will be discharged by the water pump. The whole operation process is very simple, so no need for divers to carry out underwater construction.

Embodiment 2

[0034] Embodiment 2, as shown in Figures 3 and 4, is a method for sealing water between a box body and a pile body. The water stop method is used for sealing water stop between the pile body 2 and the box body 1. A box body with a cavity 11 inside is made, and there is a gap 8 between the box body part corresponding to the cavity 11 and the pile body 2. The box body with the cavity forms a floating platform, and the pile body is a steel pipe pile. The diameter is 2.5 meters, and the annular airbag 4 with skeleton is adopted. The height of the annular airbag 4 is 0.4 meters. The inner diameter of the annular airbag is 2% larger than the outer diameter of the steel casing of the steel pipe pile. The annular airbag 4 in the gap between the pile hole and the steel pipe pile 2 is filled with water to 0.6Mpa through the inflatable tube 7, and the encircling force and tension force of the airbag reach more than 100 tons, which will produce a strong connection rigidity, relying on the ...

Embodiment 3

[0035]Embodiment 3, as shown in Figure 5, the box body is a steel sleeve box, the pile body is a steel casing, and the water-stopping method is used for sealing and water-stopping between the pile body 2 and the box body 1, and the bottom plate 3 is provided with There is an annular airbag groove 5, and a rectangular annular airbag groove 5 with a cross-sectional shape formed by connecting the side plate and the bottom panel fixedly connected with the bottom plate near the pile hole 6 is made, and placed in the annular airbag groove 5 in advance. The cross-sectional shape of the annular airbag 4 is rectangular. In order to facilitate the positioning of the airbag in the groove, the annular airbag with a rectangular cross-section is adopted. Considering that the edge of the steel plate has edges and corners and the welding seam may cut the airbag, the change of the perimeter of the airbag should not be too large. An annular airbag with a skeleton is installed. The inner diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com