Developing roller and image forming method employing the same

A developing roller and image technology, which is applied in the direction of electric recording process applying charge pattern, equipment of electric recording process applying charge pattern, electric recording technique, etc. Residual potential, contamination prevention, and scattering prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

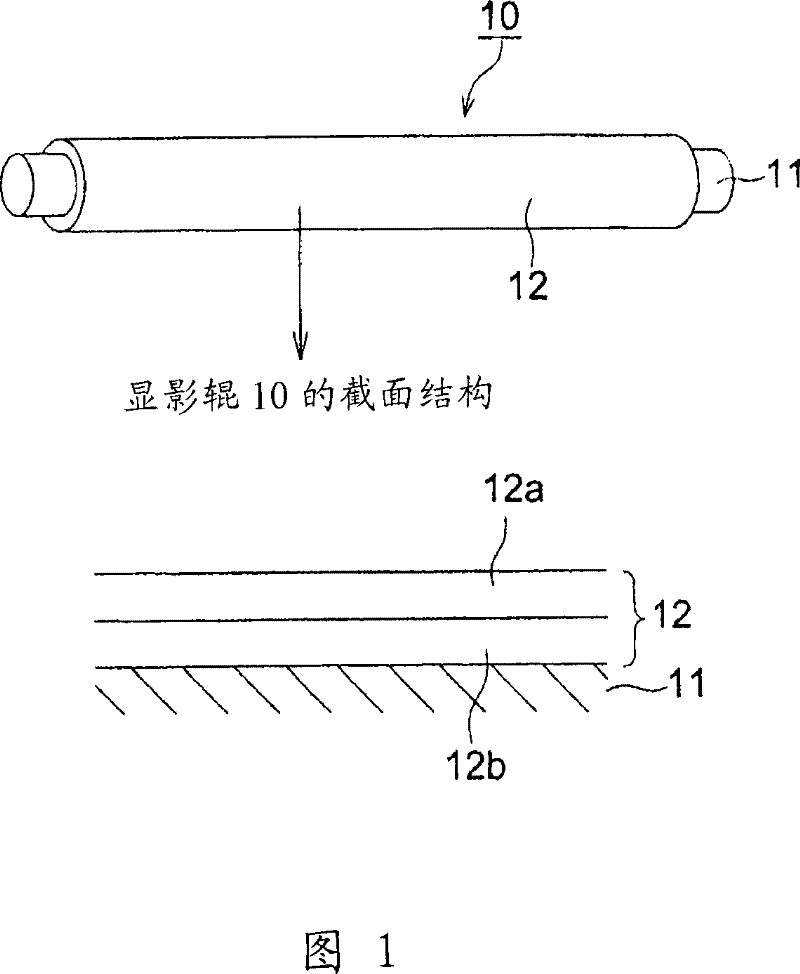

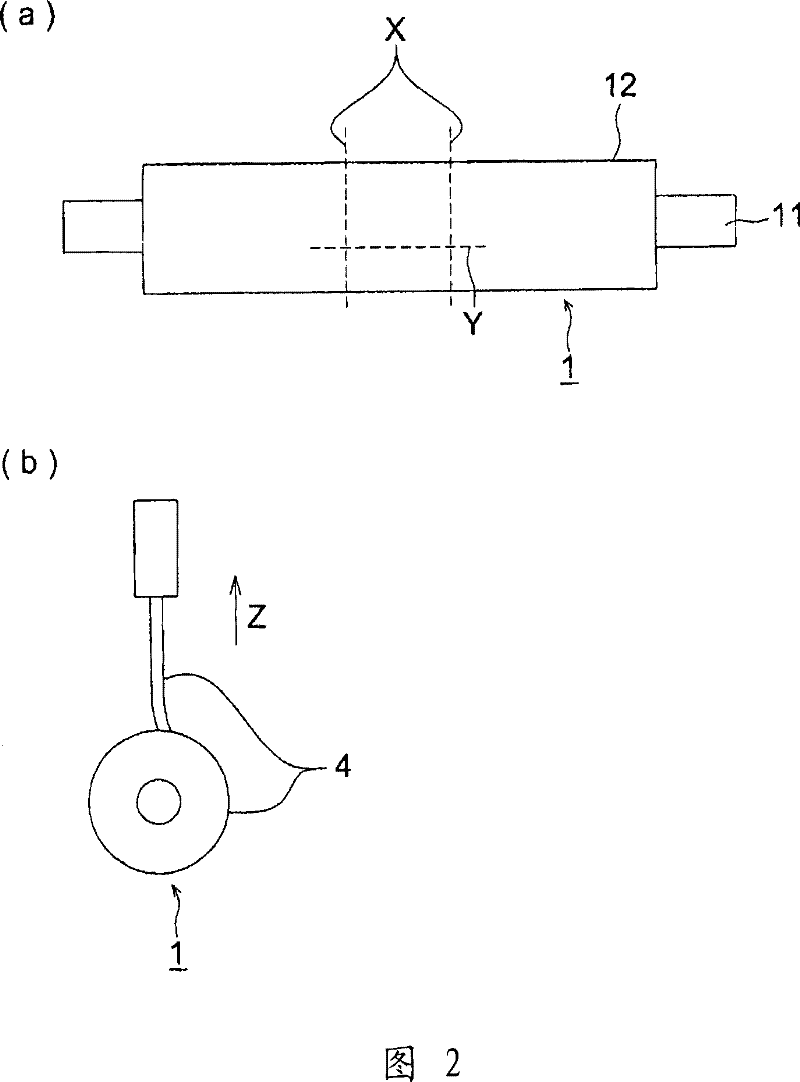

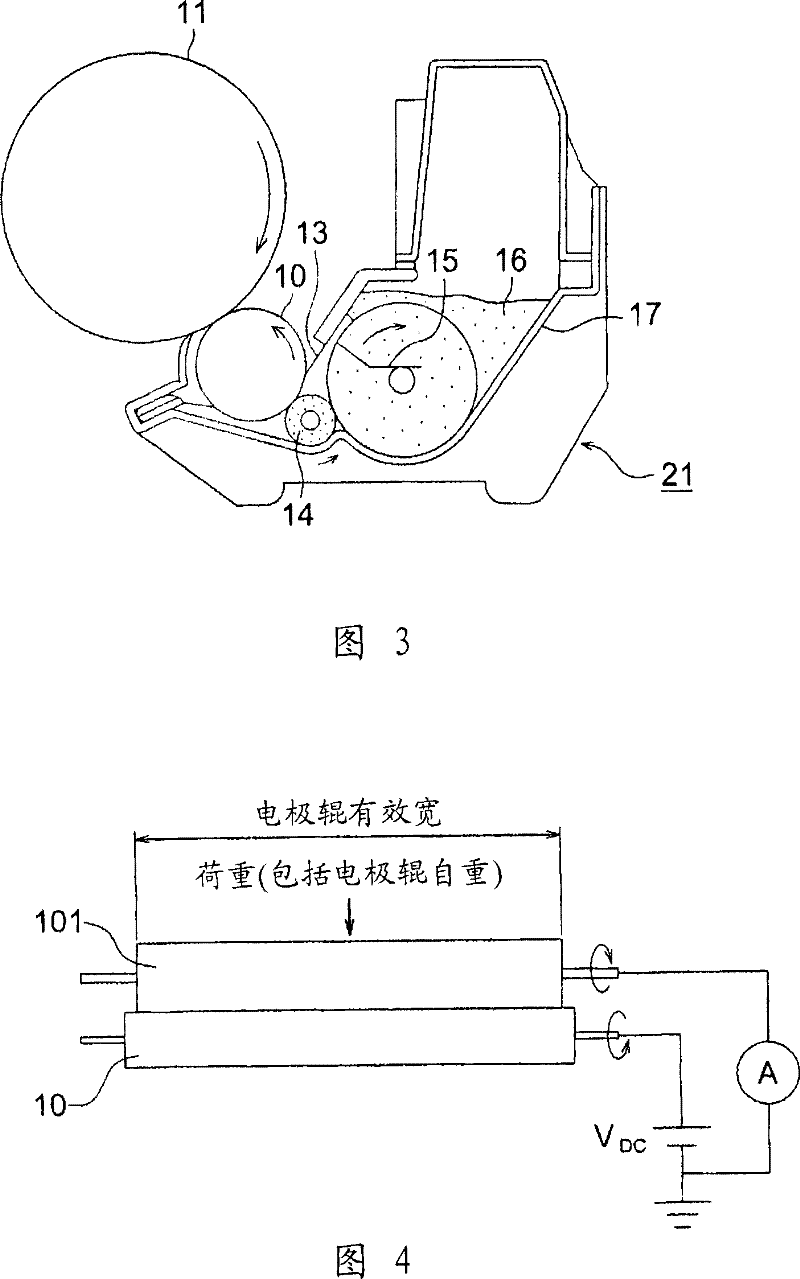

Image

Examples

Embodiment

[0295] Hereinafter, although an Example is given and the embodiment of this invention is demonstrated concretely, this invention is not limited to this. In addition, "parts" in the text means "parts by mass".

[0296] [Developing Roller Coating Solution]

[0297] (polyamide resin liquid)

[0298] (1) Production of polyamide resin-containing layer forming material 1

[0299] Polyamide resin (N-1) was mixed with polyurethane resin (Nitsupolan 5199: manufactured by Nippon Polyurethane Co., Ltd.), 30 parts of Ketchien black (carbon black) was mixed, and isopropyl alcohol was added to produce polyamide resin (N-1) 52% by mass (mass % calculated excluding volatile matter such as solvents in the drying process, the same applies hereinafter) polyamide resin-containing layer forming material 1 .

[0300] (2) Production of polyamide resin-containing layer forming material 2

[0301] Polyamide resin (N-3) was mixed with polyurethane resin (Nitsupolan 5199: manufactured by Nippon Poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com