Multi-pan continuously tea frying and drying machine

A technology of tea and drying machine, which is applied in the direction of tea treatment before extraction, etc., which can solve the problems of poor tea flow, low tea production efficiency, and insufficient tea aroma, so as to save energy and labor, low tea production cost, and high tea production efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

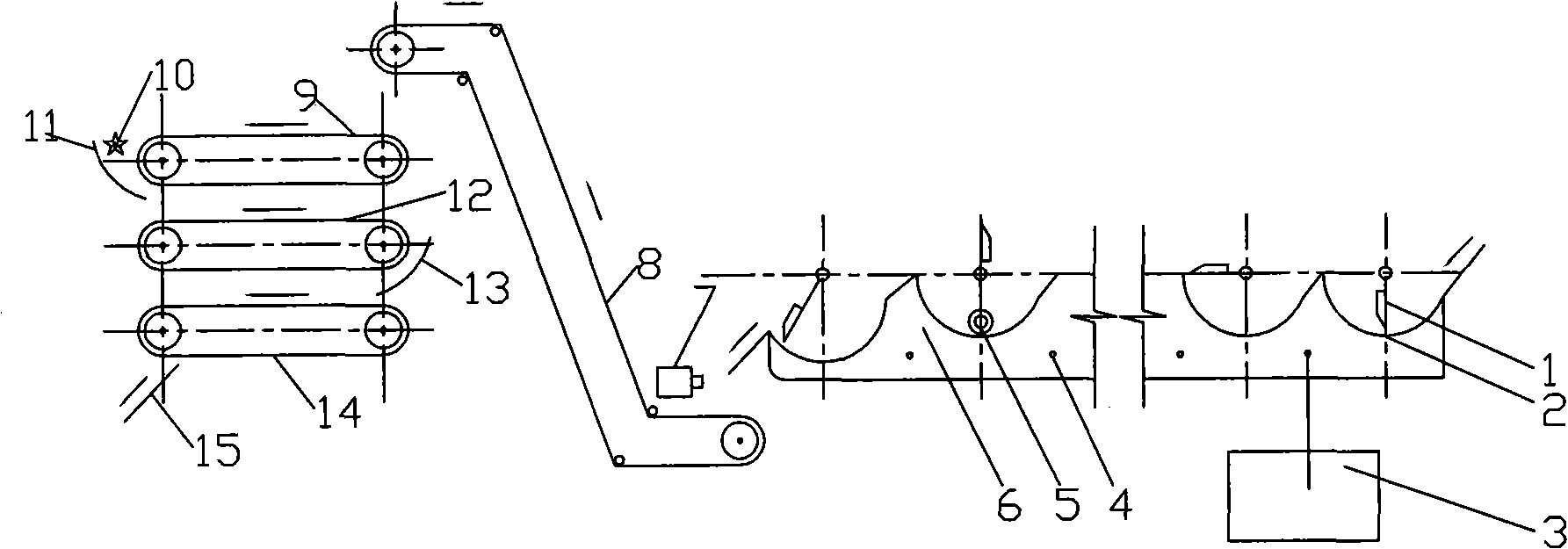

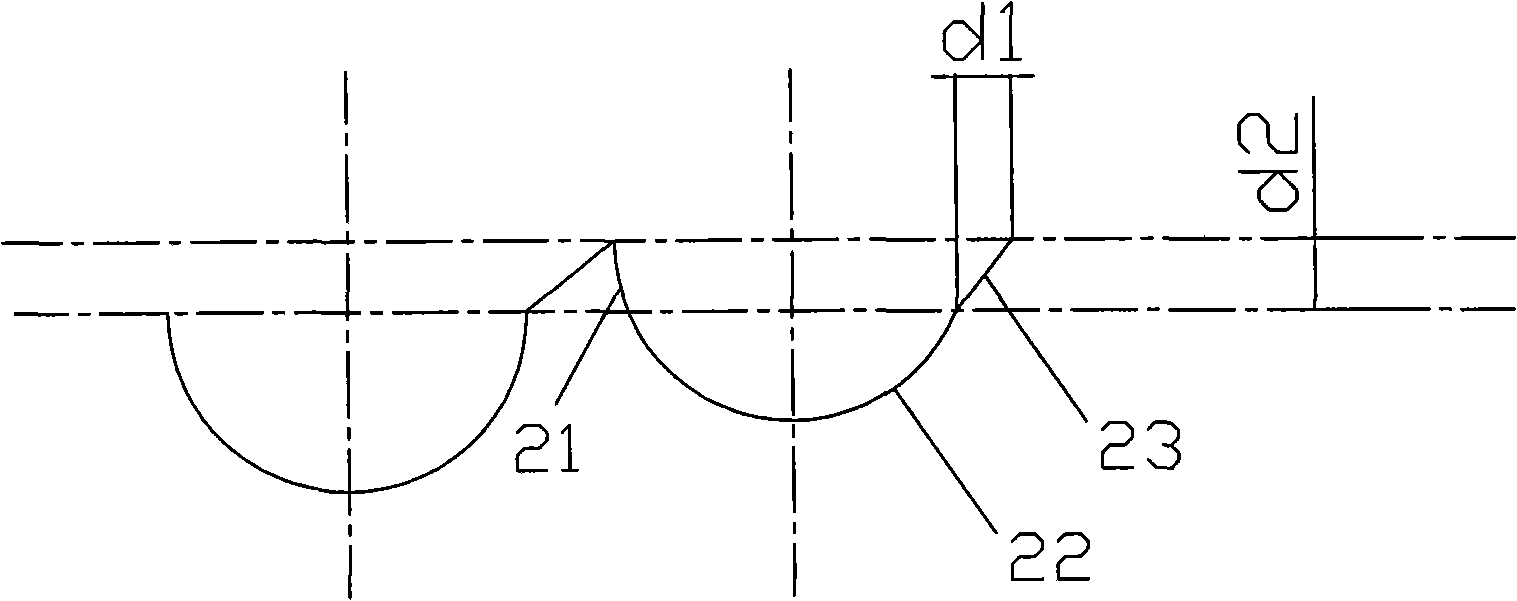

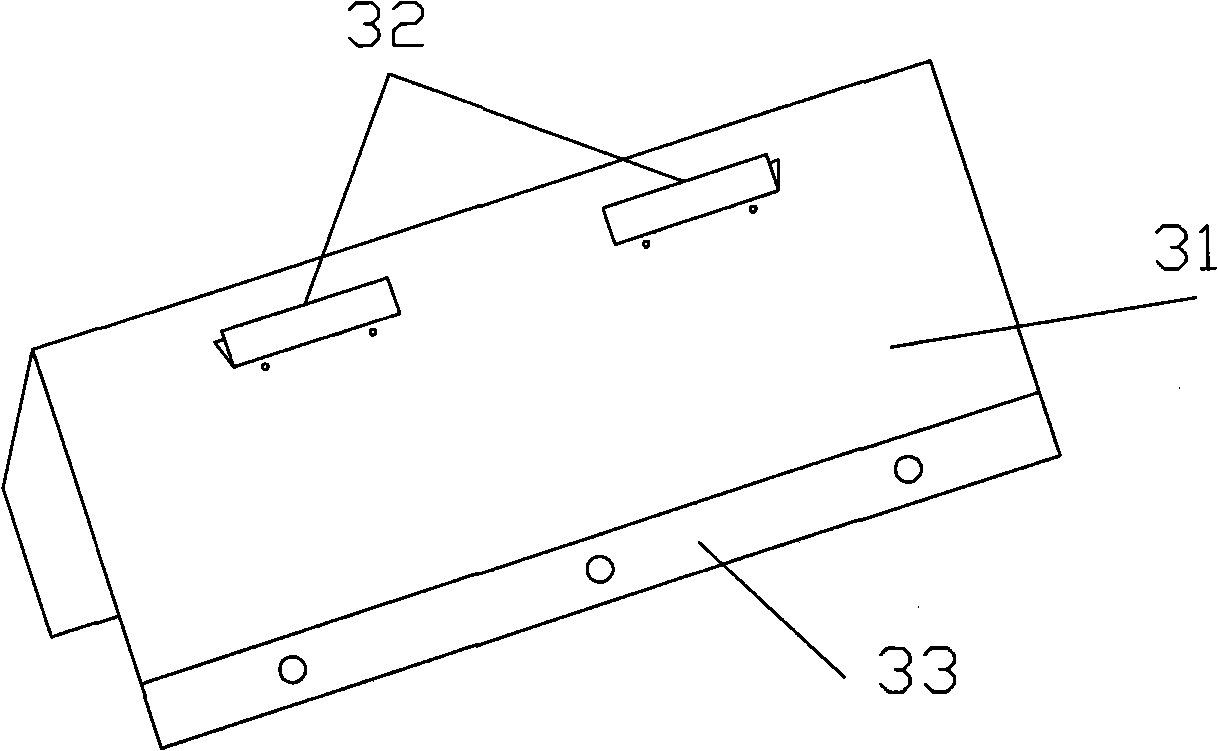

[0029] Example 1, such as figure 1 , 2 , 3, 4, 5, and 6 show a multi-pot continuous tea frying and drying machine, including a tea frying part and a tea drying part. The tea frying part includes a group of circular pots 2 on the body 6, and the drive shaft in the center of each pot 2 is provided with an electric stirrer 1 for stirring and pushing the tea leaves forward. There is a heating device 4; both the electric fryer 1 and the heating device 4 are controlled by the automatic control system 3. The drying part includes a tea delivery device and is controlled by an automatic control system. A tea cooling and annealing device is set between the tea outlet of the fried tea part and the tea inlet of the drying part; the tea delivery device is sealed in the hot roaster equipped with a heating device except for the tea outlet and the tea inlet. inside the oven.

[0030] Such as figure 1 As shown, the cooling and annealing device is an air-permeable conveyor belt machine 8; t...

Embodiment 2

[0035] Embodiment 2, a multi-pot continuous tea frying and drying machine, including a tea frying part and a tea drying part. Such as Figure 5 As shown, on the drive shaft at the center of the tank in the back section of the tea frying part, the support 52 is movably connected with the pressure roller 51 to shape the tea leaves. The pressing roller is made of an oblong metal body (such as a steel pipe), which can rotate freely in the tank, and utilizes the dead weight of the pressing roller to suppress the fried tea leaves. The weight and installation quantity of the pressing rollers can be determined according to the needs of tea making, and they can be installed in the pot at the appropriate position of the tea frying part. All the other are with embodiment 1.

Embodiment 3

[0036] Embodiment 3, a multi-pot continuous tea frying and drying machine, including a tea frying part and a tea drying part. Such as Figure 8 Shown, described frying tea part also is provided with wiper brush 81 on the drive shaft of front section pot center, and described wiper brush is movably connected on the drive shaft; To remove sticky pot tea juice. The pot wiping brush can also be folded to facilitate use (the pot wiping brush is adjusted to the working position when in use, and placed or stretched to neutral when not in use). Because the inner surface of the pot is often covered with a lot of tea juice in the early stage of greening the tea leaves, which affects the quality of tea frying, so a pot wiper brush is designed to regularly wipe off the tea juice. The pot wiper brush is made of wear-resistant, high temperature resistant, non-toxic, odorless, and slightly elastic materials (such as metal wire, stainless steel screen). All the other are with embodiment 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com