Automatic resorption type antipollution medicine adding syringe

An anti-pollution and syringe technology, applied in the field of syringes, can solve the problems of inconvenient use, difficulty in moving a push rod by hand, and high manufacturing cost, and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

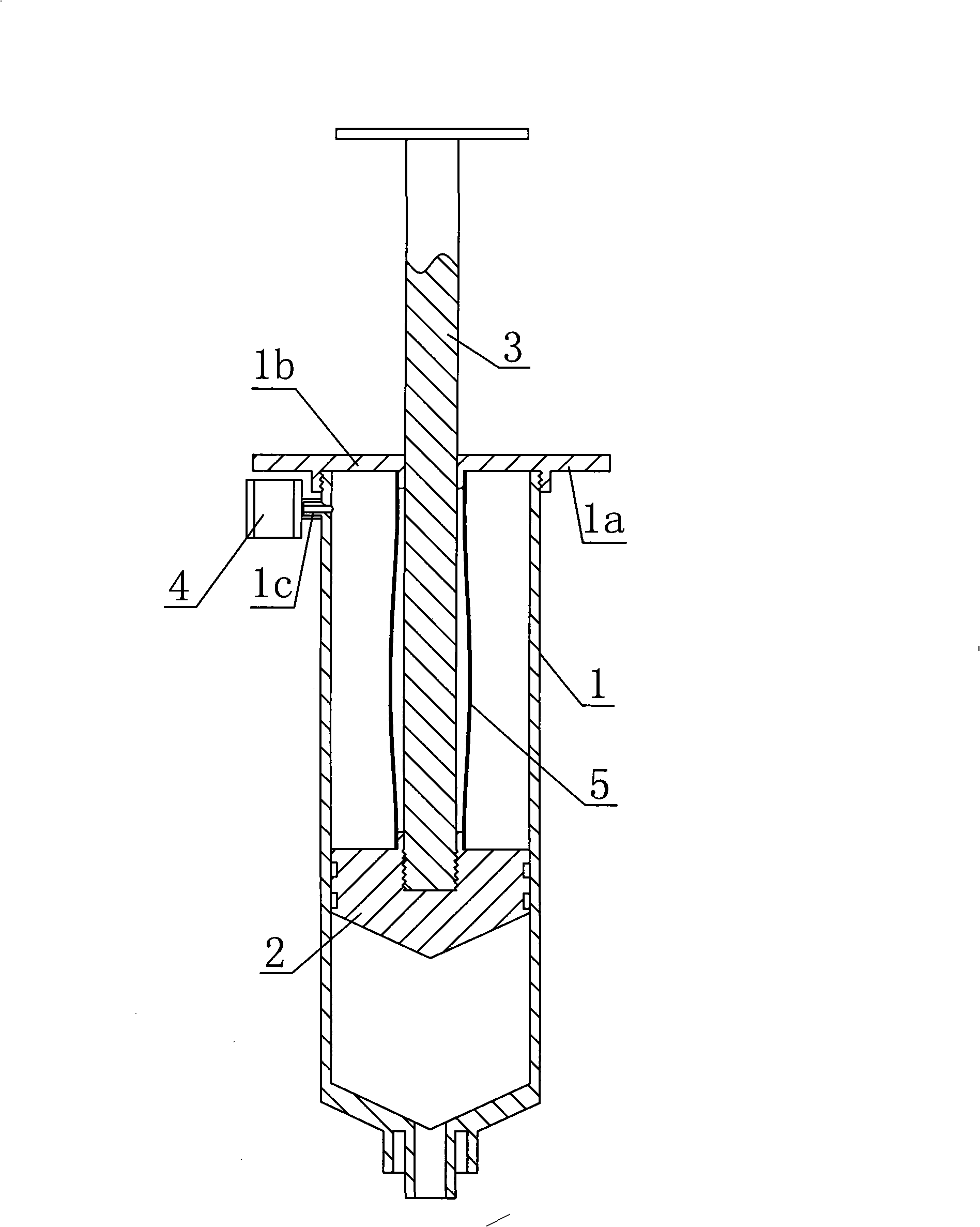

[0016] refer to figure 1 As shown, the automatic back-suction type anti-pollution dosing syringe of the present invention includes a syringe 1, a wing plate 1a arranged on both sides of the rear end of the syringe 1, a piston 2 arranged in the syringe 1, and a piston 2 connected to the lower end of the syringe 1. The columnar push rod 3 is provided with a guide cover 1b at the rear end of the needle cylinder 1. The guide cover 1b in this embodiment is formed by extending inwards from the wing 1a. The wing 1a and the guide cover 1b are connected to the needle. The cylinders 1 are threaded, which makes the processing and combination more convenient; the cylindrical push rod 3 passes through the middle of the guide cover plate 1b, and an air filter 4 is connected to the inner cavity of the syringe 1 near the wing plate 1a at the rear of the syringe 1 , the air filter 4 can adopt the molecular membrane filter commonly used in the prior art, this type of filter can pass through the...

Embodiment 2

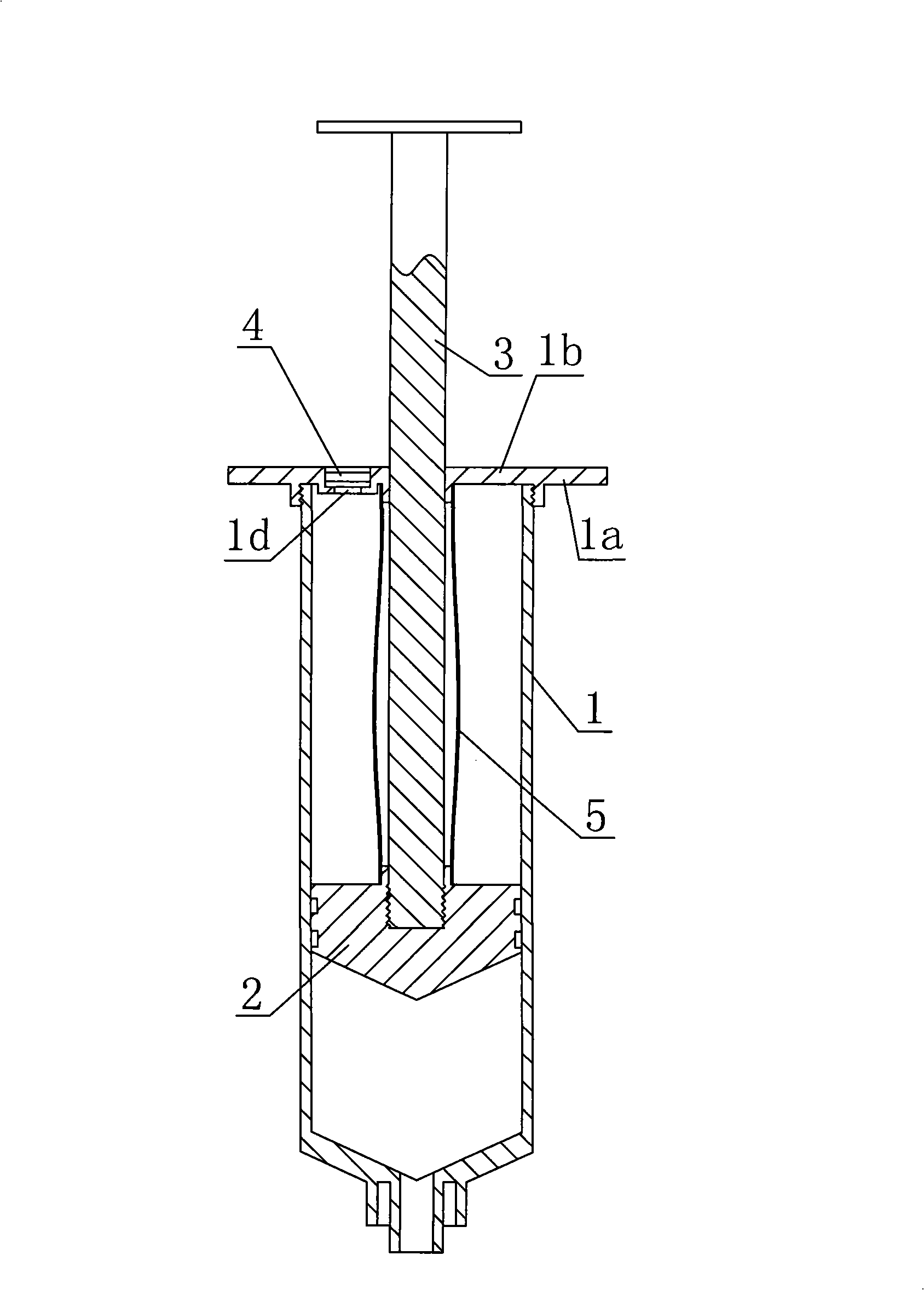

[0018] refer to figure 2 As shown, another automatic back-suction anti-pollution dosing syringe of the present invention is basically the same as Embodiment 1, except that a groove 1d is provided on the guide cover 1b, and the air filter 4 is installed in the groove Within 1d, the effect is exactly the same.

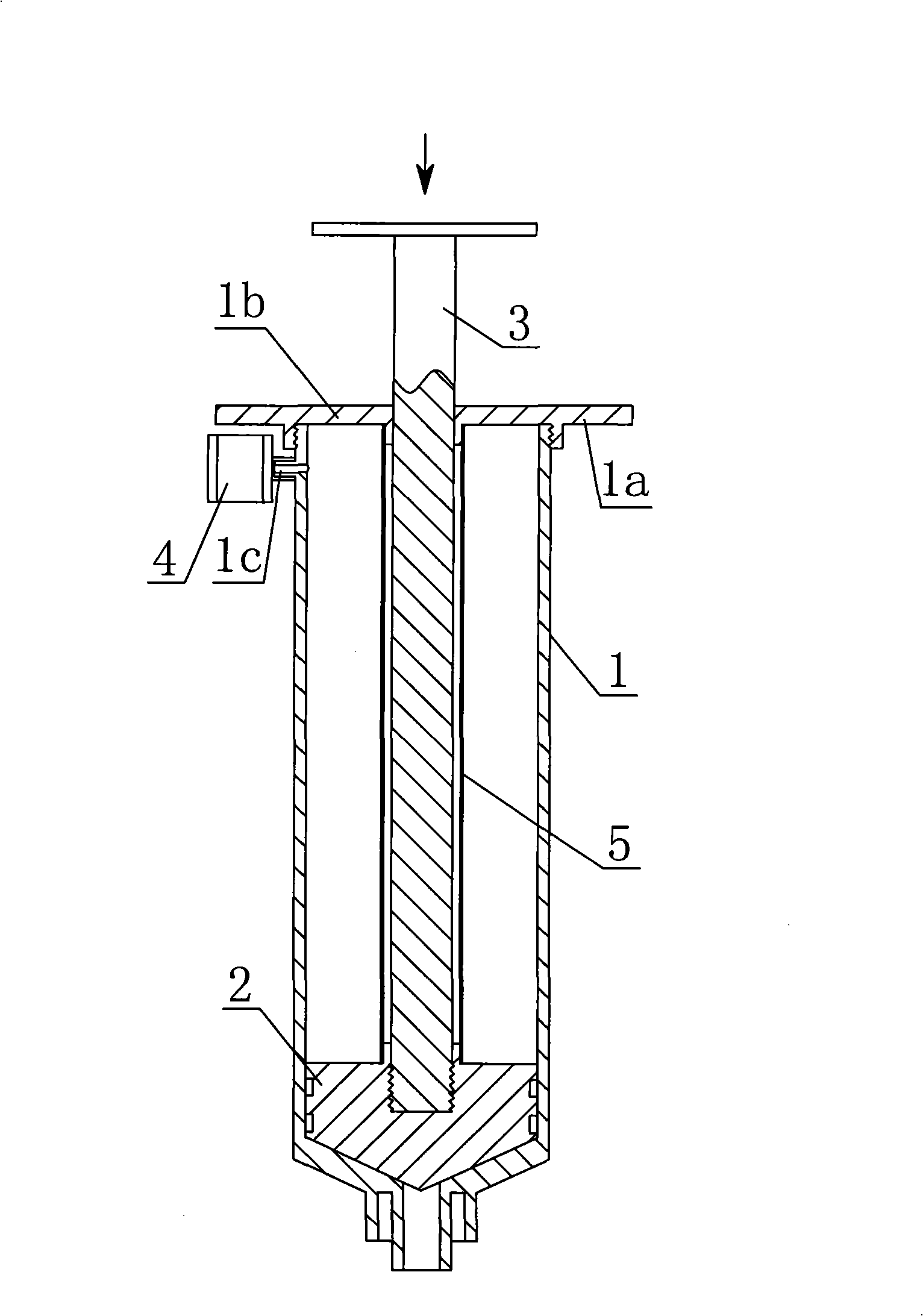

[0019] refer to image 3 , Figure 4 As shown, when the present invention is actually used, the medical personnel can conveniently press down the columnar push rod 3 with one hand, thereby driving the piston 2 to move downward. Under the action of elastic force, it moves upwards, thereby driving the piston 2 to move upwards, realizing the automatic suction of liquid medicine at the beginning stage. If more liquid medicine needs to be sucked, the medical staff will then pull the columnar push rod 3 upwards by hand until the suction is completed. Until the liquid medicine is mixed, then operations such as mixing the liquid medicine and injection are carried out. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com