Steel rail fracture vehicle-carrying non-contact fast monitoring technique

A non-contact, detection technology, applied in railway vehicle shape measuring instruments, railway car body parts, railway auxiliary equipment, etc., can solve the problems of slow monitoring speed, slow speed, high density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

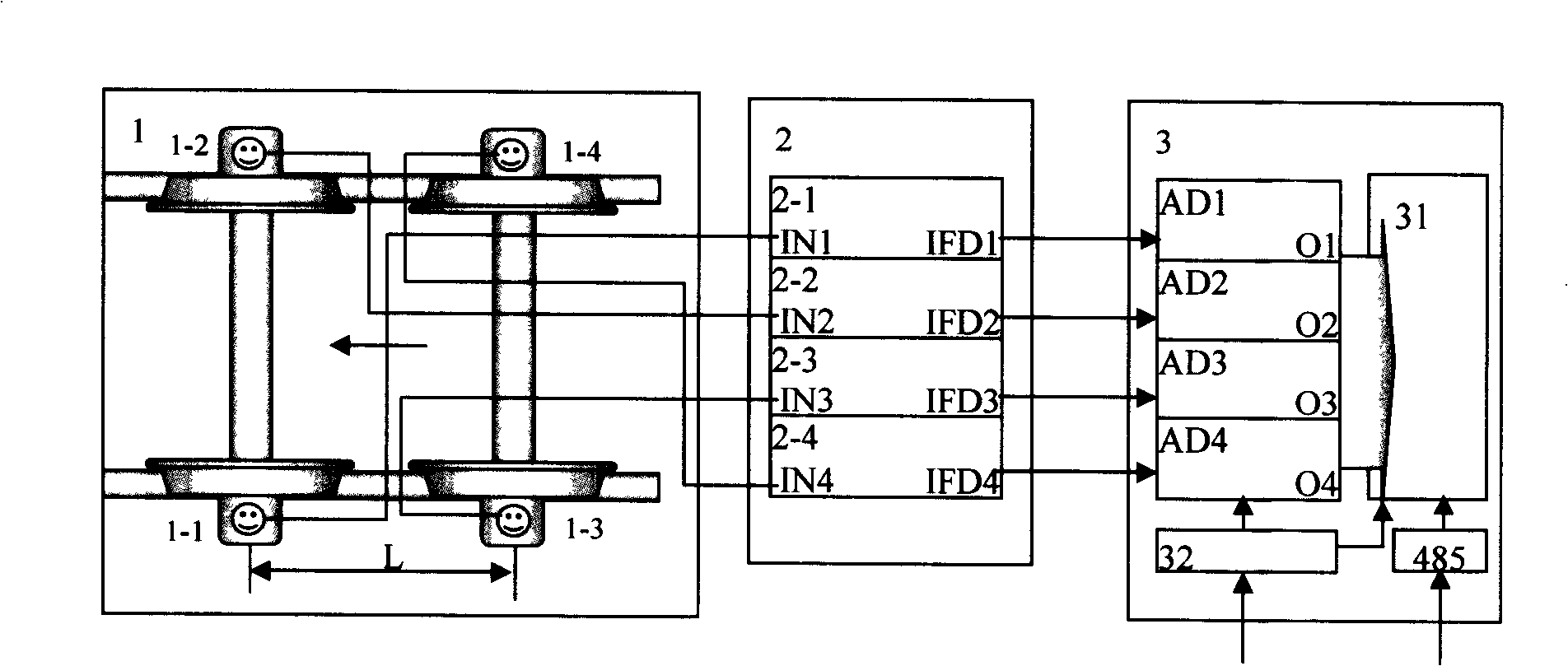

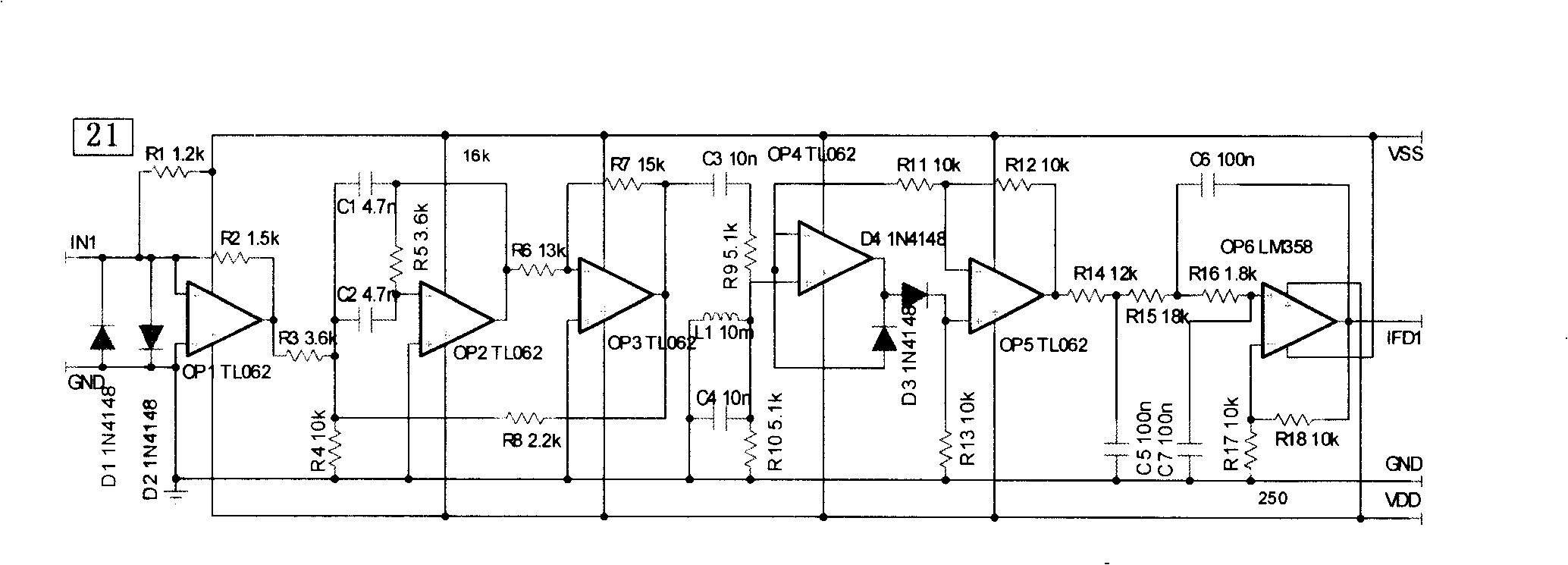

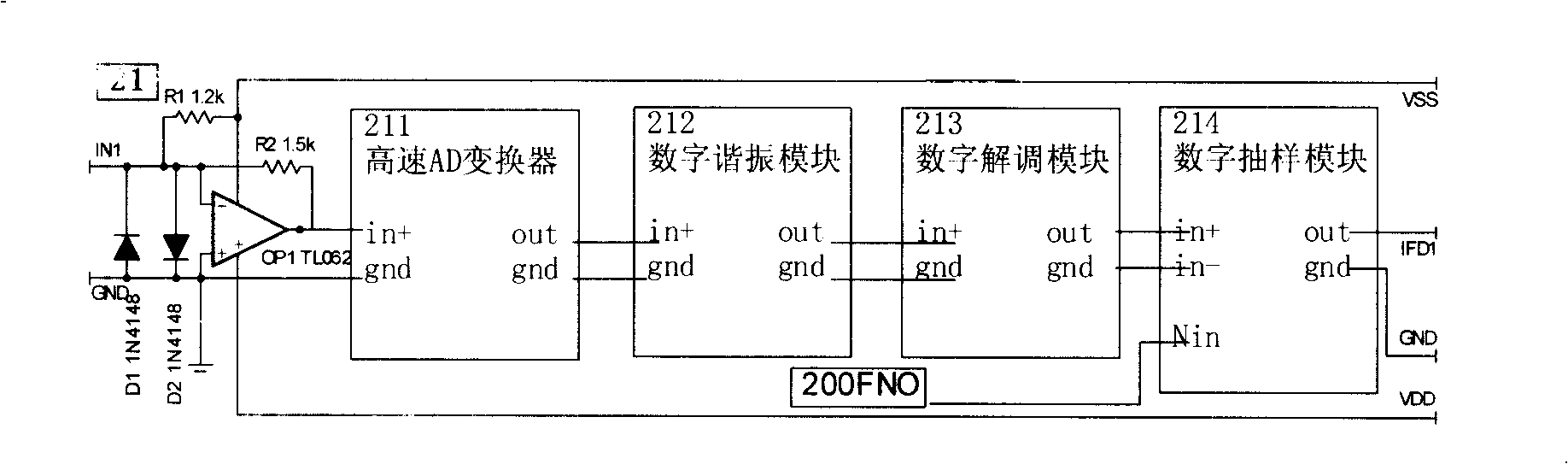

[0030] This vehicle-mounted non-contact rapid detection technology for rail fracture is characterized in that: 2n axle boxes installed on 2n axle boxes of n (n≥2) wheel pairs of locomotives and vehicles are used to detect the impact of broken rails on wheels state sensors 1-1~1-2n, and the signals of the 2n sensors are paralleled and sent to the corresponding matching 2n resonant demodulators 2; then the 2n resonant demodulators output from the 2n resonant demodulator Demodulated signal IFD 1 ~IFD 2n 2n corresponding AD channels AD sent to computer 3 in parallel 1 ~ AD 2n , controlled by the speed control signal output by the speed interface 32, to carry out automatic tracking of the vehicle speed (wheel speed), through uninterrupted continuous sampling to obtain 2n of each track monitored by each sensor and divided into two groups (left group, right Group) continuous samples are sent to the computerized broken rail diagnosis expert system 31 of the monitoring computer, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com