Separation driving circuit and control method with discharging channel

A technology for isolating drive circuits and discharge paths, applied in electrical components, output power conversion devices, etc., can solve the problems of inability to change voltage, large resistance value of resistor R2, and low level of driving waveform, and achieve the effect of avoiding false conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

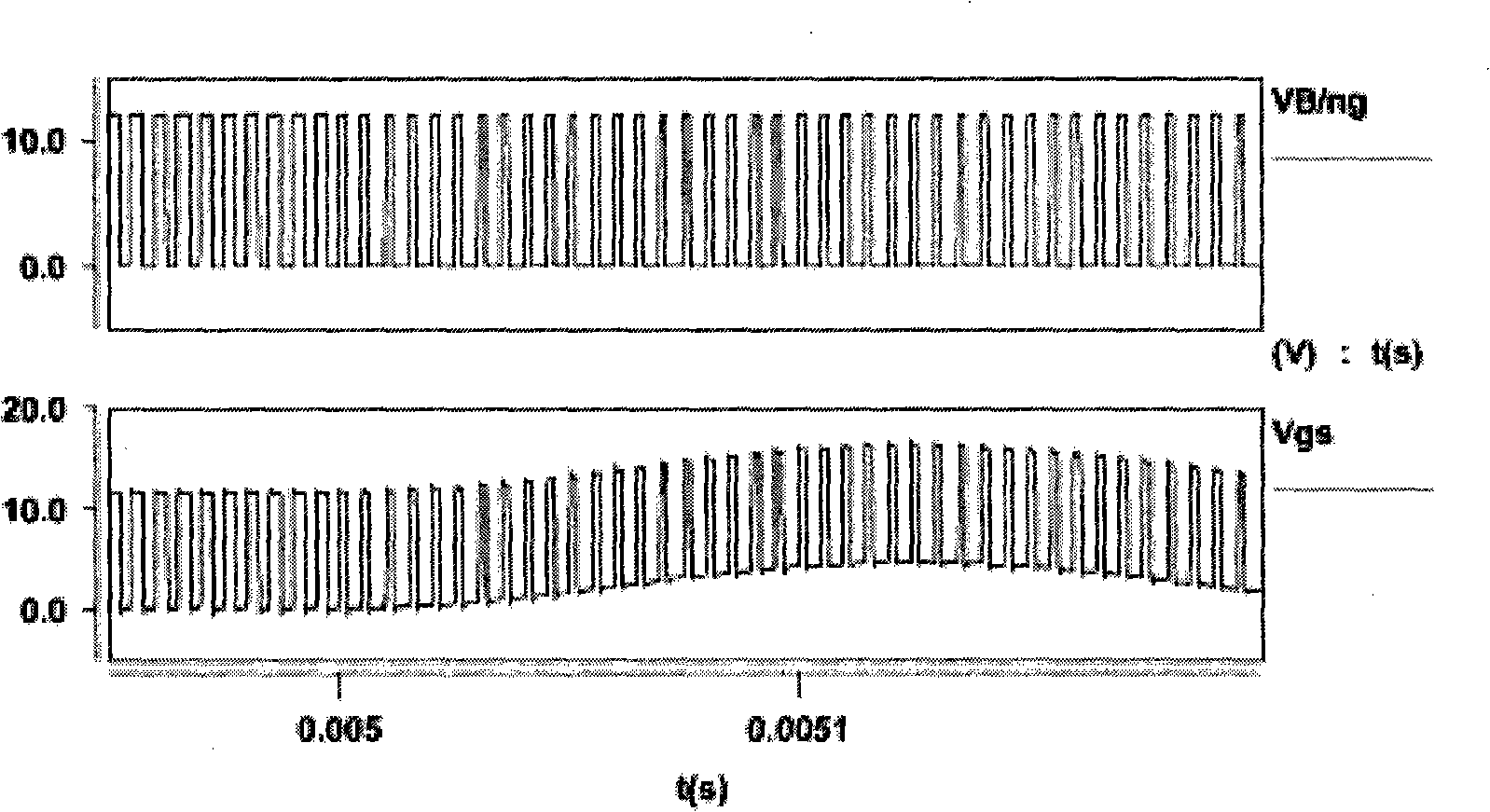

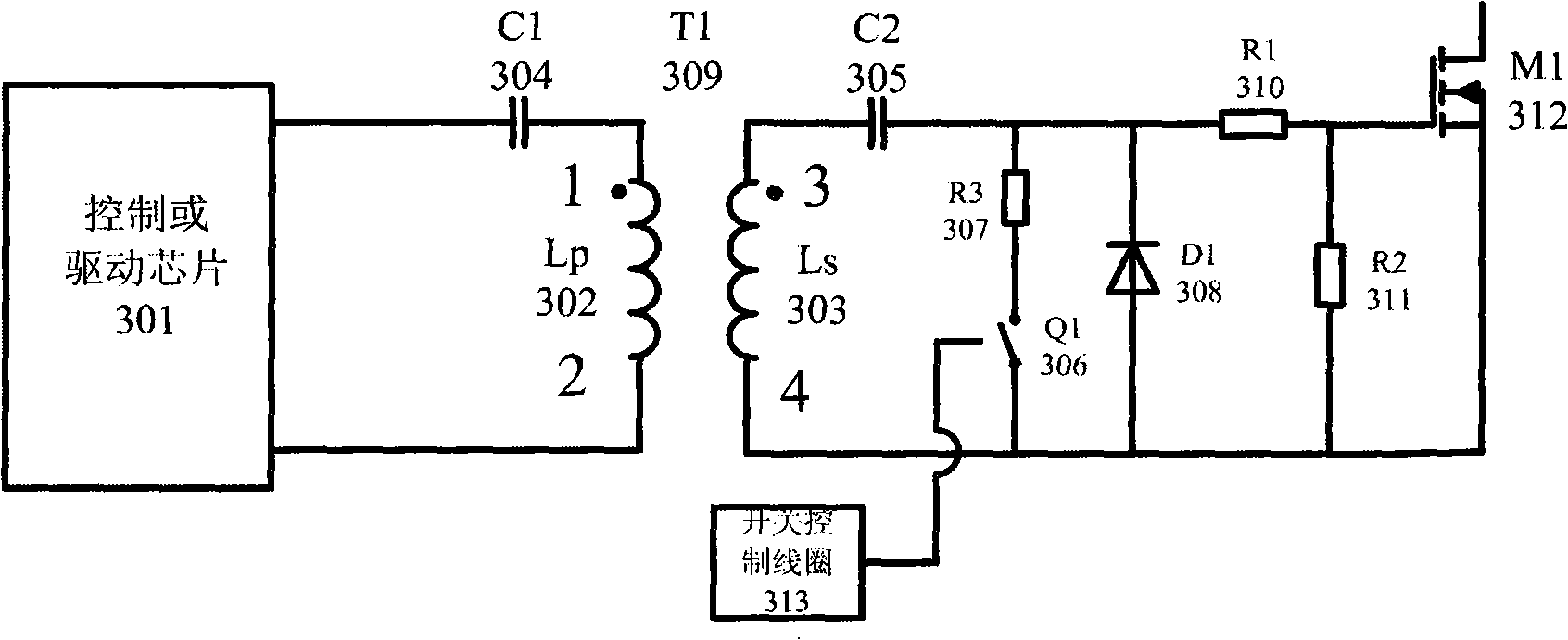

[0029] The technology of the present invention is based on the traditional isolated drive circuit, and a controllable discharge circuit is connected in parallel at both ends of the bootstrap diode 308 on the secondary side. When the duty cycle of the primary side changes rapidly from large to small, the bootstrap capacitor 305 on the secondary side can ensure rapid discharge, so that the low level of the final output driving signal is reduced to zero, preventing false conduction of the subsequent power switch tube.

[0030] The present invention is described below in conjunction with accompanying drawing:

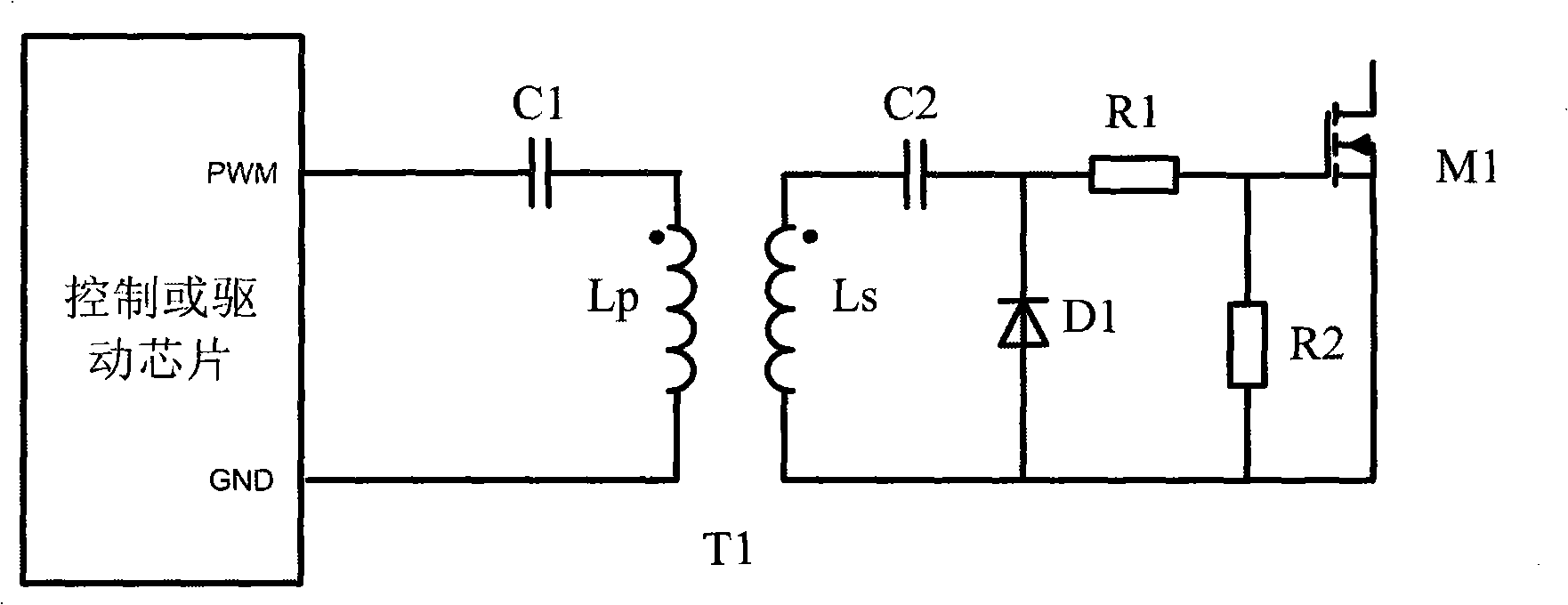

[0031] see image 3 Schematic diagram of the isolated drive circuit with discharge path of the present invention, such as image 3 As shown, the primary side input signal interface, the driving pulse from the control circuit enters the circuit of the present invention; the primary side DC blocking capacitor C1304 is connected to the driving pulse entrance and the primary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com